In today's rapidly evolving industrial landscape, the significance of Perforated Stainless Steel Mesh cannot be overstated. According to a report by MarketsandMarkets, the global market for perforated metals is projected to reach USD 1.5 billion by 2025, fueled by its increasing adoption across diverse sectors such as construction, automotive, and food processing. This versatile material not only enhances functionality but also improves aesthetic appeal, making it a preferred choice for architects and engineers alike. With applications ranging from filtration systems to architectural facades, Perforated Stainless Steel Mesh offers unparalleled durability and resistance to corrosion, ensuring longevity and safety in various environments. As industries continue to innovate, the demand for this material is set to grow, highlighting its importance in ongoing technological advancements and sustainable practices.

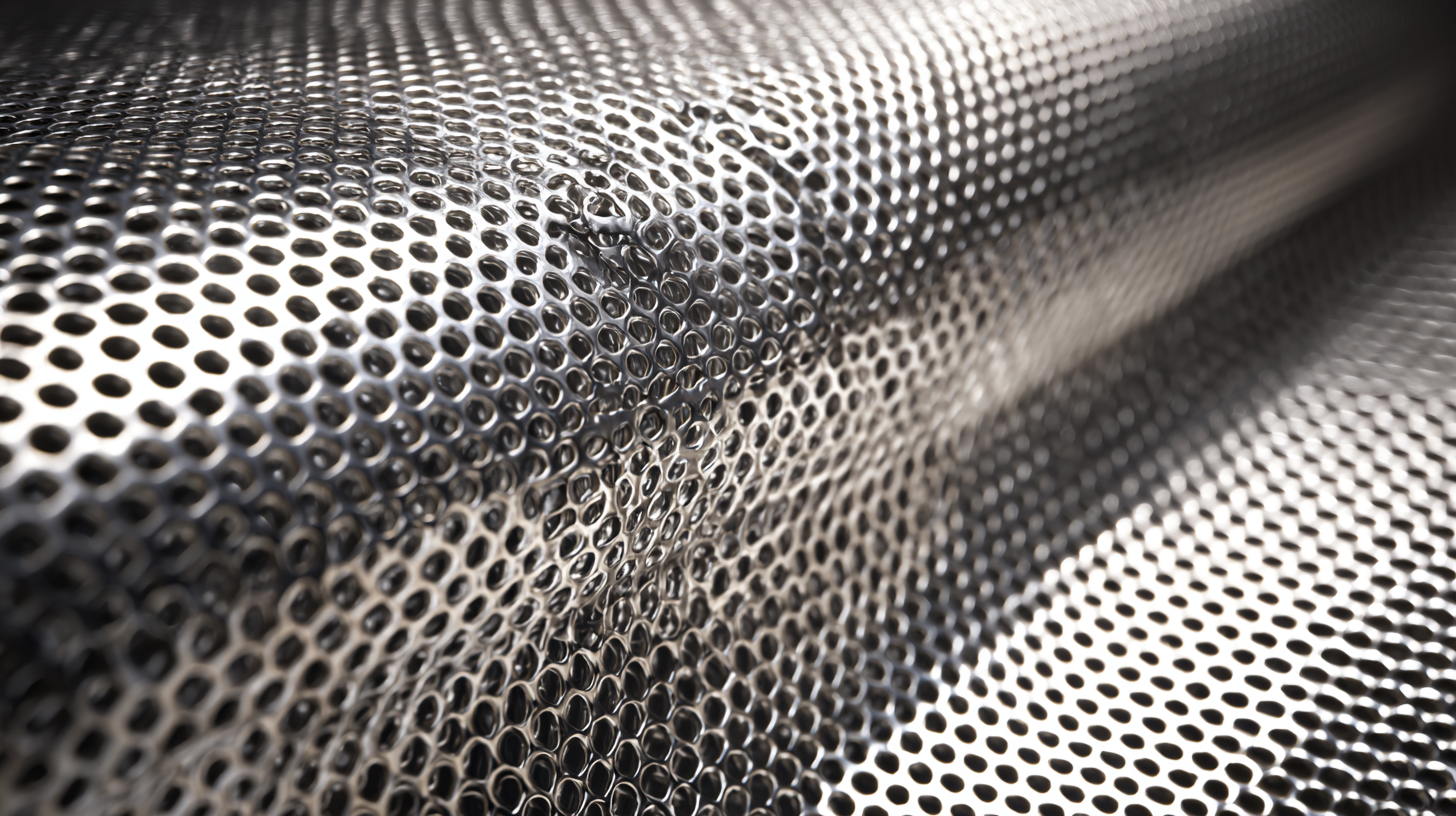

Perforated stainless steel mesh is renowned for its remarkable versatility and strength, making it an essential material across various industries. One of the key features of this mesh is its unique perforation pattern, which can be customized to meet specific requirements. This allows manufacturers to control factors such as airflow, light transmission, and fluid flow, which are critical in applications ranging from architecture to filtration systems. With its corrosion resistance and durability, perforated stainless steel mesh can withstand harsh environments, ensuring longevity and reliability in industrial use.

In addition to its functional benefits, the aesthetic appeal of perforated stainless steel mesh cannot be overlooked. Its sleek appearance enhances architectural designs, providing both safety and style in applications like facades, railings, and interior partitions. The mesh can also be utilized in various creative ways, such as art installations and decorative elements, further expanding its application range. Moreover, its easy maintenance and recyclability contribute to sustainable practices in manufacturing and construction, aligning with the growing environmental consciousness across industries.

Perforated stainless steel mesh is revolutionizing the construction and architecture industries with its unique blend of aesthetic appeal and functionality. Used in a variety of applications, from facades to acoustic panels, this versatile material offers both durability and design flexibility. According to a report by Smithers Pira, the global market for architectural mesh is projected to reach USD 3.3 billion by 2026, highlighting its growing importance in modern architectural projects.

One innovative application is its use in building facades, where it not only enhances visual interest but also improves energy efficiency. The perforations allow for natural ventilation, reducing the need for artificial climate control systems. A study published in the Journal of Building Physics found that buildings utilizing perforated mesh can see energy savings of up to 20%.

Tips: When considering perforated stainless steel mesh for your project, think about the size and layout of the perforations – they can significantly affect both the aesthetic quality and functional performance. Additionally, always opt for high-grade stainless steel to enhance longevity and resistance to environmental challenges. Choose a supplier who provides custom solutions for unique project needs to truly leverage the versatility of this material.

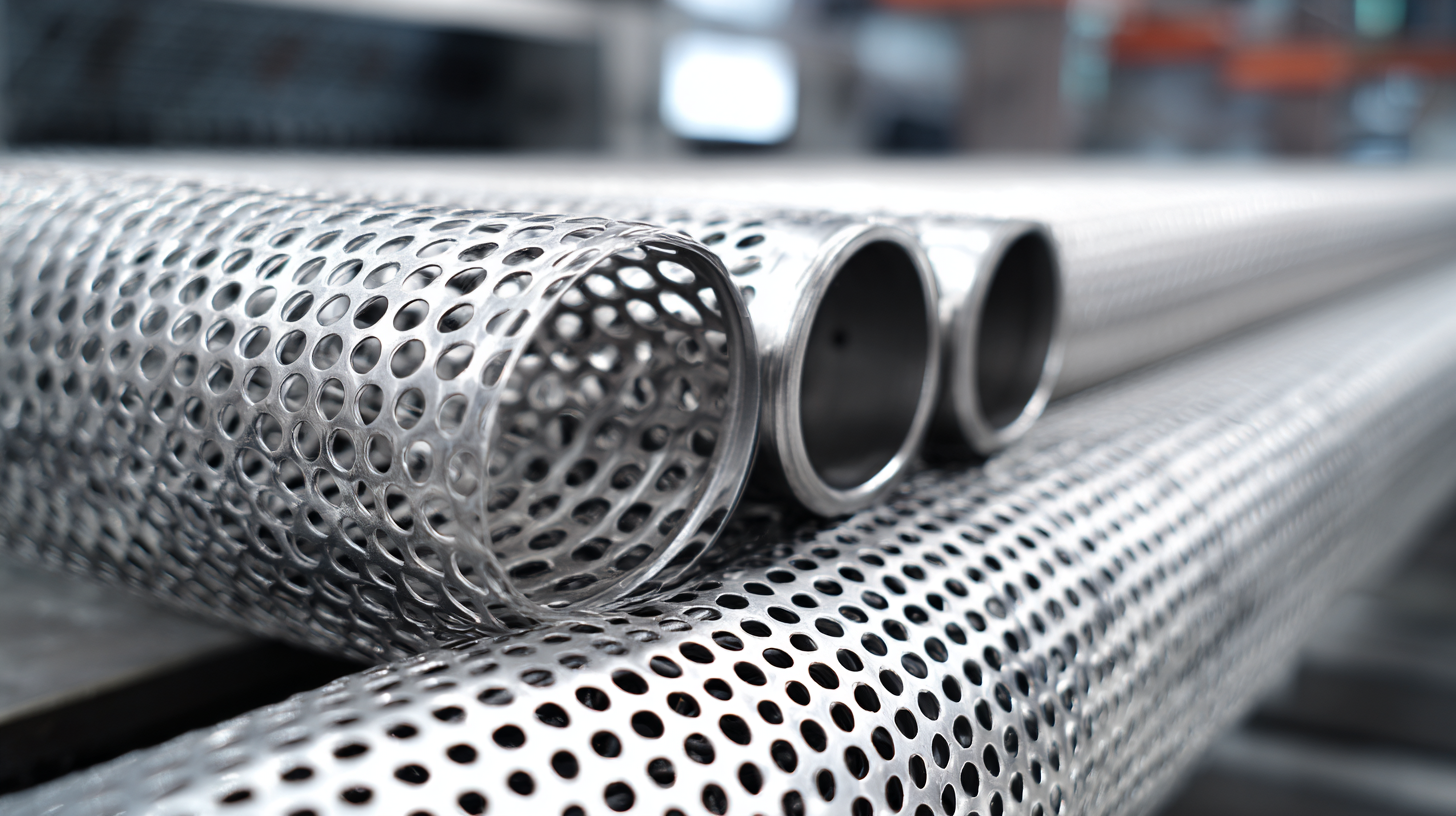

Perforated stainless steel mesh plays a crucial role in filtration and separation processes across various industries, thanks to its durability, corrosion resistance, and customizable openings. In the water treatment sector, for instance, the Global Water Treatment Market is projected to reach USD 1,232 billion by 2027, demonstrating the increasing reliance on effective filtration systems. The precision engineering of perforated mesh allows for optimal flow rates while effectively trapping particulate matter, making it an essential component in ensuring clean drinking water.

Perforated stainless steel mesh plays a crucial role in filtration and separation processes across various industries, thanks to its durability, corrosion resistance, and customizable openings. In the water treatment sector, for instance, the Global Water Treatment Market is projected to reach USD 1,232 billion by 2027, demonstrating the increasing reliance on effective filtration systems. The precision engineering of perforated mesh allows for optimal flow rates while effectively trapping particulate matter, making it an essential component in ensuring clean drinking water.

In the food processing industry, perforated stainless steel mesh is indispensable for ensuring hygiene and safety standards. According to a report by ResearchAndMarkets, the global food safety testing market is expected to grow to USD 29 billion by 2025. The ability of perforated mesh to facilitate air circulation while preventing contamination positions it as a vital tool in processes like drying and cooking. Furthermore, its resistance to heat and chemicals ensures longevity and reliability in equipment utilized for filtration and separation tasks, contributing to improved efficiency in production lines.

The automotive industry is undergoing a significant transformation, and one of the key players in this evolution is perforated stainless steel mesh. This innovative material, known for its strength and durability, is increasingly being utilized to enhance vehicle performance and design. Its lightweight yet robust nature allows for improved fuel efficiency without compromising structural integrity. The versatility of perforated stainless steel mesh means it can be integrated into various automotive components, from body panels to interior elements, providing both functional and aesthetic benefits.

Moreover, the outstanding corrosion resistance of stainless steel makes it an ideal choice for automotive applications, where exposure to various environmental factors can lead to degradation. Recently, advancements in materials technology, such as concrete-filled stainless steel tube members, are also highlighting the high strength and durability that perforated stainless steel can bring to the table. This tech not only increases resilience but also enhances safety features in vehicles. As the automotive industry continues to innovate, perforated stainless steel mesh stands out as a crucial element in driving progress toward more efficient, durable, and attractive vehicles.

This chart depicts the impact rating of perforated stainless steel mesh within the automotive industry across several key factors, including weight reduction, cost efficiency, aesthetic appeal, durability, and noise reduction. The values range from 1 to 10, showcasing how perforated stainless steel mesh contributes to various aspects of automotive manufacturing.

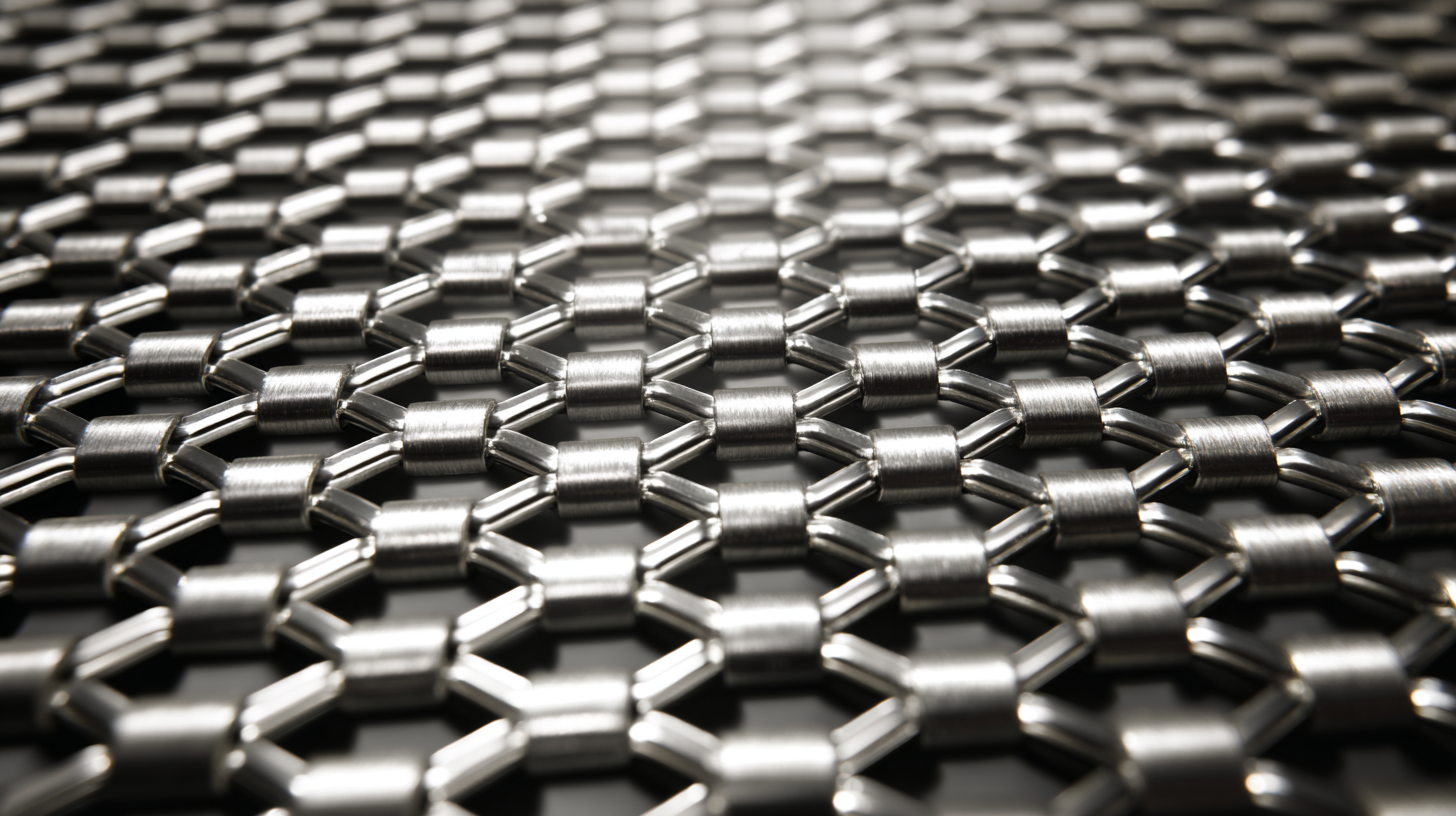

As we approach 2025, the perforated stainless steel mesh industry is poised for significant advancements driven by innovation and increasing demand across various sectors. Recent reports from Market Research Future highlight a projected growth rate of 4.5% annually in the industrial mesh market, emphasizing the expanding applications in construction, automotive, and filtration systems. Key trends include the integration of smart technologies, where perforated mesh can be combined with sensors for real-time monitoring, enhancing both functionality and efficiency.

Sustainability also plays a pivotal role in shaping the future of perforated stainless steel mesh technology. A recent study by Allied Market Research notes that sustainable materials are gaining traction, with an anticipated market share increase of up to 30% for eco-friendly mesh solutions by 2025. This shift not only meets the growing environmental standards but also reduces lifecycle costs for manufacturers and consumers alike. Innovations in manufacturing processes are expected to yield more resilient and versatile products, further broadening the scope of applications in industries ranging from filtration to architectural design.