The robust and adaptable nature of materials often dictates their application across various industries, and one such standout is the perforated copper sheet. This innovative material effortlessly merges functionality with aesthetic appeal, making it a popular choice in modern design and industrial settings. Perforated copper sheets not only offer impressive structural integrity but also present a canvas for creative expression, thanks to their unique ability to blend form and function. From architectural facades to artistic installations and acoustic panels, the versatility of perforated copper sheets is unparalleled. In this exploration, we will delve into the diverse applications and benefits of this remarkable material, illuminating its role in shaping contemporary aesthetics and enhancing industrial efficiency, establishing itself as a cornerstone in both design and manufacturing.

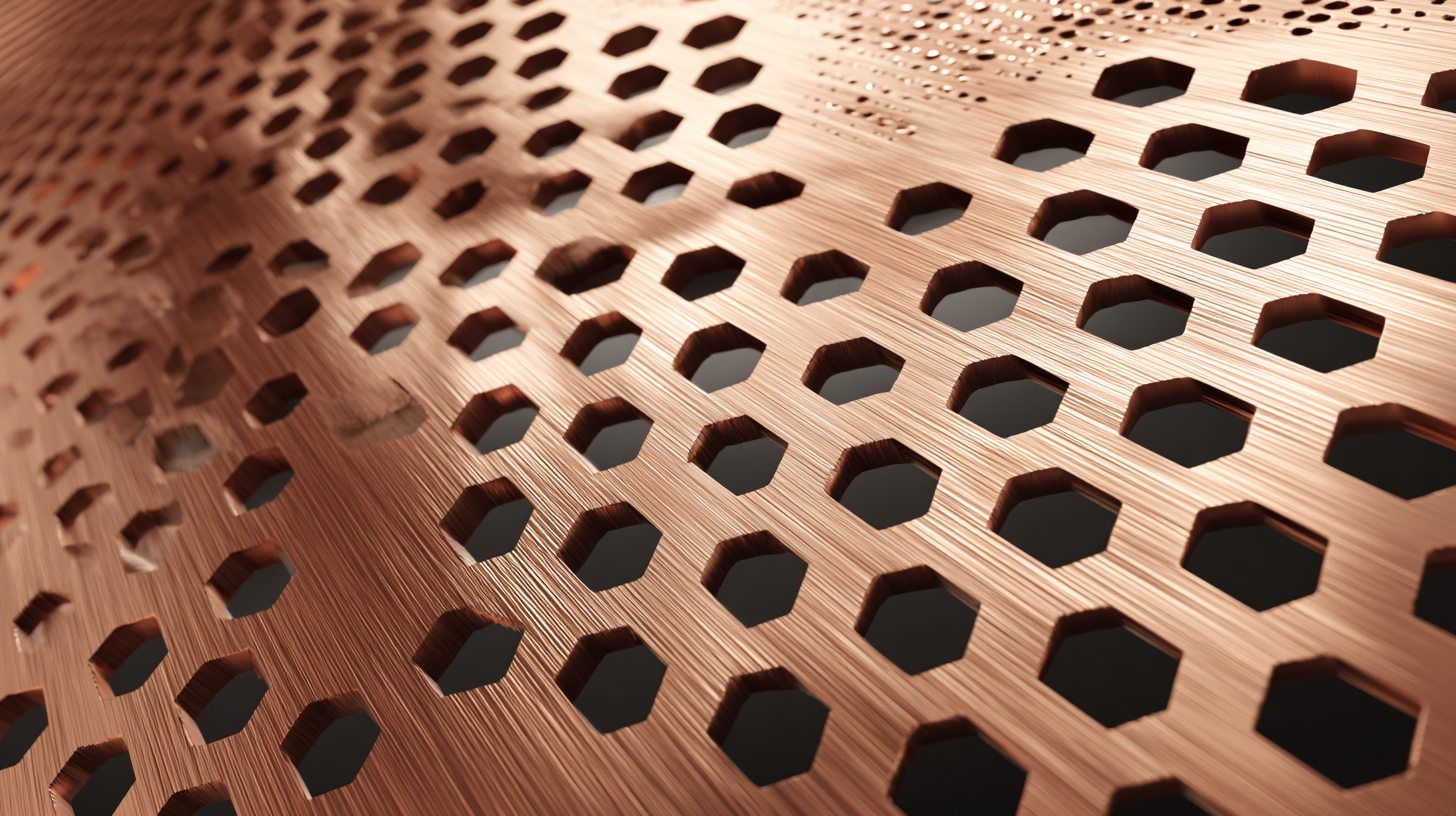

Perforated copper sheets have emerged as a popular choice in contemporary design, celebrated not only for their functionality but also for their unique aesthetic appeal. The intricate patterns created by perforation allow light to filter through, resulting in a dynamic interplay of shadow and illumination that can transform any space. A report by Grand View Research highlights that the architectural segment is one of the key drivers behind the rising demand for decorative metal sheets, estimating growth rates of approximately 5.6% CAGR through 2025. This trend reflects a broader shift within the industry towards incorporating materials that offer both visual interest and practical benefits.

The warm, reddish hue of copper offers a timeless quality that enhances various design elements, from fixtures to façades. According to a recent analysis by the Global Market Insights Group, the versatility of copper's finish contributes to its increasing application in interior and exterior designs, as it seamlessly complements various materials, including wood, glass, and stone. Moreover, the antimicrobial properties of copper make it an ideal choice for high-traffic areas while facilitating modern design’s emphasis on hygiene. As a result, perforated copper sheets not only elevate the aesthetic quality of modern architecture but also align with contemporary needs, reinforcing their place as a staple in both residential and industrial applications.

This bar chart illustrates the various modern applications of perforated copper sheets, showcasing their unique aesthetic appeal and functional versatility across different industries.

Perforated copper sheets have emerged as a versatile material in contemporary architectural design, celebrated for their aesthetic appeal and functional properties. According to a report by the Copper Development Association, the global demand for copper in construction applications is projected to grow at a CAGR of 4.5% between 2023 and 2028. This rise is largely attributed to the increasing use of innovative building materials, including perforated copper sheets, which are favored for their durability, thermal conductivity, and resistance to corrosion.

Architects and designers are leveraging the unique qualities of perforated copper sheets to create striking facades and interior elements. These sheets not only contribute to energy efficiency by allowing natural light to penetrate while reducing heat gain, but they also enhance sound insulation. As noted in a study by the American Institute of Architects, using perforated metals can reduce overall energy consumption in buildings by up to 20%. By integrating aesthetic design with functional benefits, architects are able to create spaces that are not only visually stunning but also sustainable and practical.

Perforated copper sheets have emerged as a pivotal material in modern industrial settings due to their unique combination of functionality and aesthetic appeal. The process of perforation allows for tailored designs that not only reduce weight but also enhance airflow and sound absorption. These attributes make them ideal for applications ranging from architectural facades to ventilation systems in manufacturing plants. In environments where temperature control and noise reduction are essential, perforated copper sheets can provide effective solutions, improving overall operational efficiency.

Additionally, the intrinsic properties of copper, such as its corrosion resistance and antimicrobial characteristics, make these sheets particularly valuable in settings where hygiene is critical, such as food processing and medical facilities. The versatility of perforated copper sheets enables designers and engineers to integrate them seamlessly into various applications, ensuring they meet specific functional requirements while also contributing to the visual identity of the space. Whether used in decorative elements or structural components, the functional benefits of perforated copper sheets continue to be recognized across diverse industrial sectors.

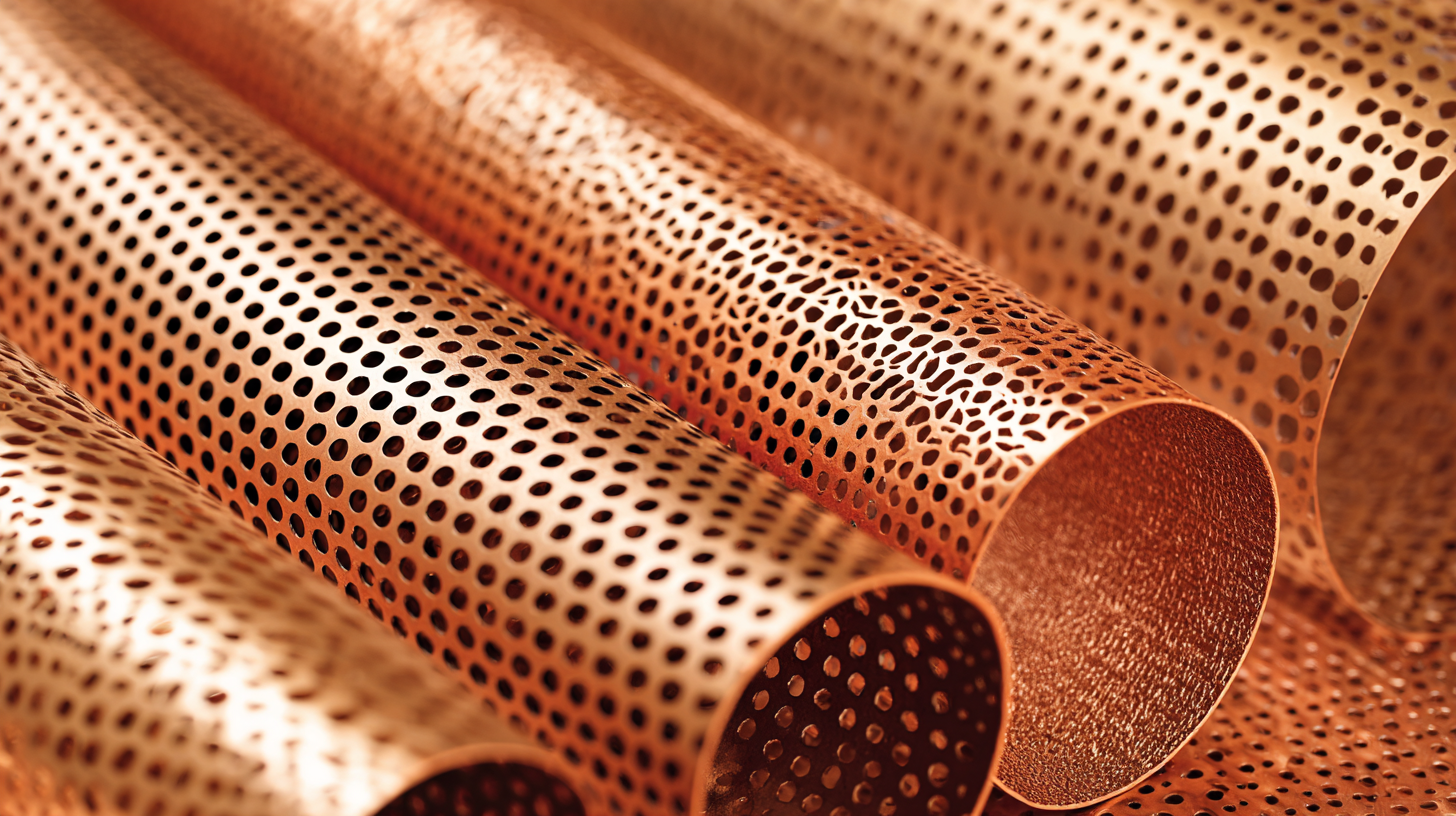

Perforated copper sheets have emerged as a vital material in modern craftsmanship, largely due to their inherent sustainability and durability. According to a report by the Copper Development Association, copper boasts a recycling rate of over 80%, significantly reducing the environmental footprint associated with mining and processing new materials. This high recyclability aligns well with the growing demand for sustainable building practices, as architects and designers seek to incorporate materials that contribute to a circular economy.

Perforated copper sheets have emerged as a vital material in modern craftsmanship, largely due to their inherent sustainability and durability. According to a report by the Copper Development Association, copper boasts a recycling rate of over 80%, significantly reducing the environmental footprint associated with mining and processing new materials. This high recyclability aligns well with the growing demand for sustainable building practices, as architects and designers seek to incorporate materials that contribute to a circular economy.

In addition to their eco-friendly attributes, perforated copper sheets are highly durable. A study published in the Journal of Architectural Engineering highlights that copper can last over 100 years when properly maintained, making it an excellent choice for both aesthetic and functional applications. Its resistance to corrosion ensures that it retains its visual appeal and structural integrity over decades, even in challenging environments. The unique properties of copper also allow for customization in design, providing both beauty and practicality, making it a preferred choice in various modern design applications.

The future of perforated copper sheets is poised for significant growth, driven by their unique characteristics and innovative applications across various sectors. According to a recent report by MarketsandMarkets, the global market for perforated metals is expected to reach $4.56 billion by 2026, with copper sheets playing a key role due to their antimicrobial properties, aesthetic appeal, and excellent conductivity. As designers and engineers increasingly recognize these advantages, the demand for perforated copper sheets in architectural applications, such as facades and interior design elements, continues to rise.

In the manufacturing sector, the versatility of perforated copper sheets is being embraced for industrial processes where airflow regulation and material efficiency are critical. The use of advanced perforation techniques allows for customizable designs that meet specific operational needs. A study by the Freedonia Group highlights that the demand for advanced copper products will grow by over 3% annually through 2025, underscoring the role of perforated designs in enhancing performance and sustainability. As industries seek to innovate and optimize, perforated copper sheets stand out as a material that bridges functionality and modern design, reflecting current trends in eco-friendly manufacturing and aesthetic customization.

| Application Area | Design Benefit | Industry Use | Future Trends |

|---|---|---|---|

| Architectural Elements | Aesthetic Appeal | Building Facades | Sustainable Materials |

| Interior Design | Unique Textures | Decorative Panels | Customization Trends |

| Industrial Filtration | Enhanced Durability | Manufacturing Equipment | Automation Integration |

| Lighting Solutions | Light Diffusion | Fixtures and Shades | Smart Lighting Designs |

| Acoustics | Sound Absorption | Studios and Auditoriums | Innovative Sound Solutions |