Perforated steel panels have gained traction in architectural design and functional applications. As industry expert Dr. Emily Zhang notes, “These panels provide both aesthetic appeal and practical utility.” Recent reports indicate a growing demand for such materials, projecting a 12% annual growth rate in the next five years.

Designers favor perforated steel panels for their versatility. They can be used for facades, canopies, and even interior layouts. The ability to control light and air penetration adds value to these structures. However, the implementation process is not without challenges. Finding the right balance between design intent and structural capabilities often requires careful consideration.

Despite the advantages, it’s crucial to reflect on the long-term sustainability of materials. Not all perforated panels are created equal. The choice of steel and the perforation pattern can significantly impact performance and durability. Engaging with industry resources and professionals is essential for making informed decisions.

Perforated steel panels have gained traction in architectural design due to their unique versatility. These panels not only serve aesthetic purposes but also enhance functionality. According to the American Institute of Steel Construction, perforated panels reduce material weight by 30% compared to solid sheets. This contributes to sustainability and efficiency in construction projects.

Using these panels can create dynamic facades that change appearance with light. They help control airflow and noise, improving overall comfort in spaces. The National Institute of Standards and Technology found that perforated materials can decrease energy consumption in buildings by up to 15%. However, the design process can be challenging. Opting for the wrong hole size might lead to insufficient ventilation or unintended visual distractions.

Further, maintenance can pose issues if the panels become dirtied or stained. They require appropriate treatments to maintain longevity. Adjusting for aesthetics versus practicality often leads designers to rethink their initial concepts. Balancing functionality with visual harmony demands a keen eye and thoughtful planning. Perforated panels present an exciting but complex opportunity in modern architecture.

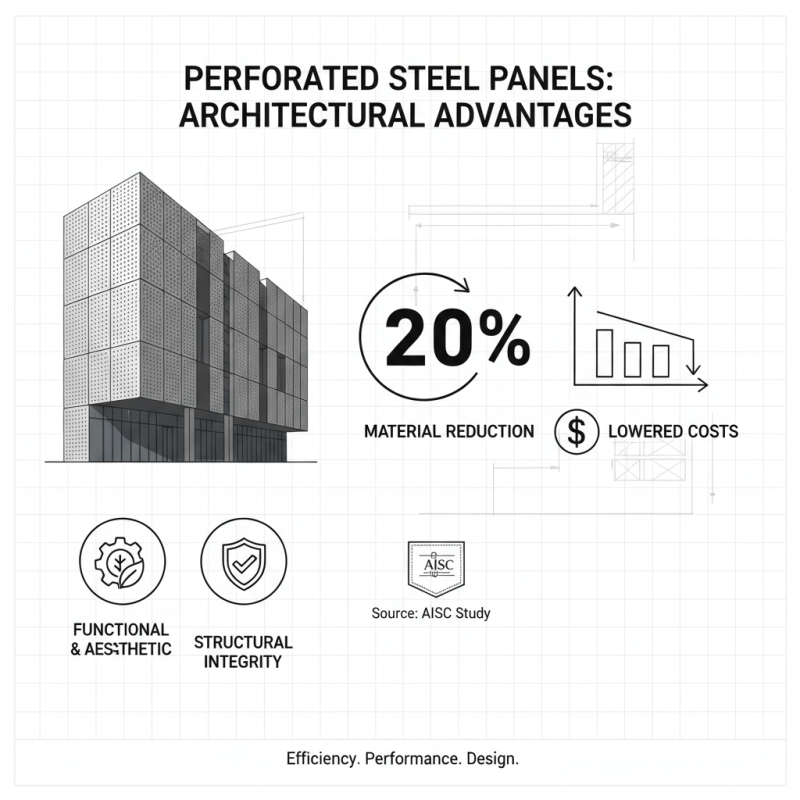

Perforated steel panels offer numerous advantages in architectural design. They’re both functional and aesthetic, blending performance with visual appeal. According to a recent study by the American Institute of Steel Construction (AISC), these panels can reduce material usage by up to 20% while providing adequate structural integrity. This efficiency helps in lowering costs, which is critical in today's competitive construction environment.

The versatility of perforated steel panels allows for various applications. They can be used for facades, sunshades, or even partition walls. These panels can also enhance ventilation and natural light while maintaining privacy. For instance, a report from the National Steel Construction Association (NSCA) states that buildings using perforated panels can achieve up to 25% energy savings in cooling. However, designers must carefully consider panel patterns and hole sizes to balance aesthetics and functionality.

Despite their benefits, challenges exist. The installation process can be tricky. Depending on size, panels might require precise alignment. Some projects face delays due to miscalculations in measurements. Architects need to communicate clearly with contractors to avoid potential issues. Continuous improvement in design practices is essential to maximize the potential of perforated steel panels.

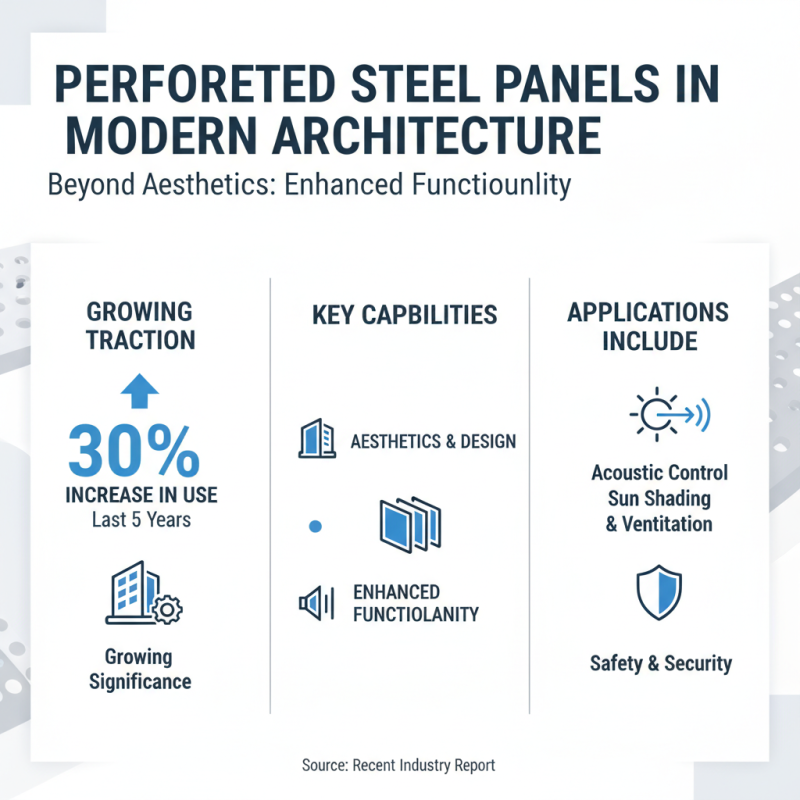

Perforated steel panels are gaining traction in construction. Their capabilities extend beyond aesthetics. They enhance functionality in various applications. According to a recent industry report, perforated metal usage has increased by 30% over the last five years. This rise indicates their growing significance in modern architecture.

These panels offer excellent ventilation. In commercial buildings, they improve air circulation while maintaining privacy. Many architects choose them for facades and interior partitions. The spacing and pattern of holes can be customized. However, ensuring the right design is crucial. Poorly designed panels may compromise structural integrity.

Another functional use is light control. Perforated steel panels can filter sunlight effectively. They reduce heat gain, which lowers energy costs. Yet, achieving the desired light quality can be challenging. Designers must balance openness and shade. Proper calculation of hole size and distribution is vital for success.

Perforated steel panels offer endless design possibilities. They can transform both commercial and residential spaces. The customization options are vast. Designers can create unique patterns that enhance aesthetics while maintaining functionality. According to a report by the Steel Construction Institute, 70% of architects value aesthetics in their material choices. This highlights the importance of perforated designs.

Tips: Consider using complex geometric patterns for a modern look. They can add visual interest to any structure. Incorporate brand logos or motifs for a personalized touch. Remember that balance is key. A highly intricate design may overwhelm the space.

Moreover, perforated panels contribute to sustainability. They can provide natural ventilation and light, reducing energy consumption. However, not all patterns offer the same performance benefits. Some designs can obstruct airflow more than intended. It's wise to test prototypes before full-scale application. A well-informed choice can lead to both beauty and efficiency.

| Design Aspect | Description | Customization Options | Common Patterns |

|---|---|---|---|

| Visual Aesthetics | Enhances building facade by creating dynamic shadows and light play. | Colors, finishes, and perforation sizes. | Geometric, organic, and custom designs. |

| Acoustic Properties | Can absorb sound, reducing noise pollution in urban areas. | Perforation diameter and distribution for sound control. | Honeycomb, wave, and staggered patterns. |

| Sustainability | Recyclable material, low environmental impact. | Recycled steel options and eco-friendly finishes. | Natural themed patterns and motifs. |

| Installation Flexibility | Easily integrated into various architectural forms. | Custom sizes and fixings based on structure. | Panelized designs and modular setups. |

| Maintenance | Durable and low-maintenance option for exteriors. | Coatings that resist rust and corrosion. | Simple and sleek designs that minimize dirt accumulation. |

When installing perforated steel panels, understanding the techniques involved is crucial. Proper alignment is essential for a uniform appearance. Using a level tool ensures panels are straight and even. The installation process typically involves securing panels with bolts or screws. The choice of fasteners depends on the panel size and weight. It’s important to select materials that resist corrosion, especially in outdoor settings.

Maintenance of perforated steel panels can be less complex than expected. Regular inspections help identify wear and tear. The surfaces may require cleaning to remove dirt and grime, which can accumulate over time. In a recent industry report, about 30% of maintenance issues stem from neglecting these inspections. Additionally, some perforated panels may need repainting every 5-10 years, depending on their exposure conditions.

Despite their durability, factors like humidity and pollutants can affect the longevity of perforated steel. Understanding the environmental impact on these panels is critical. There is often a lack of awareness about how pollutants can accelerate corrosion. This emphasizes the need for consistent maintenance checks and an informed approach to installation.