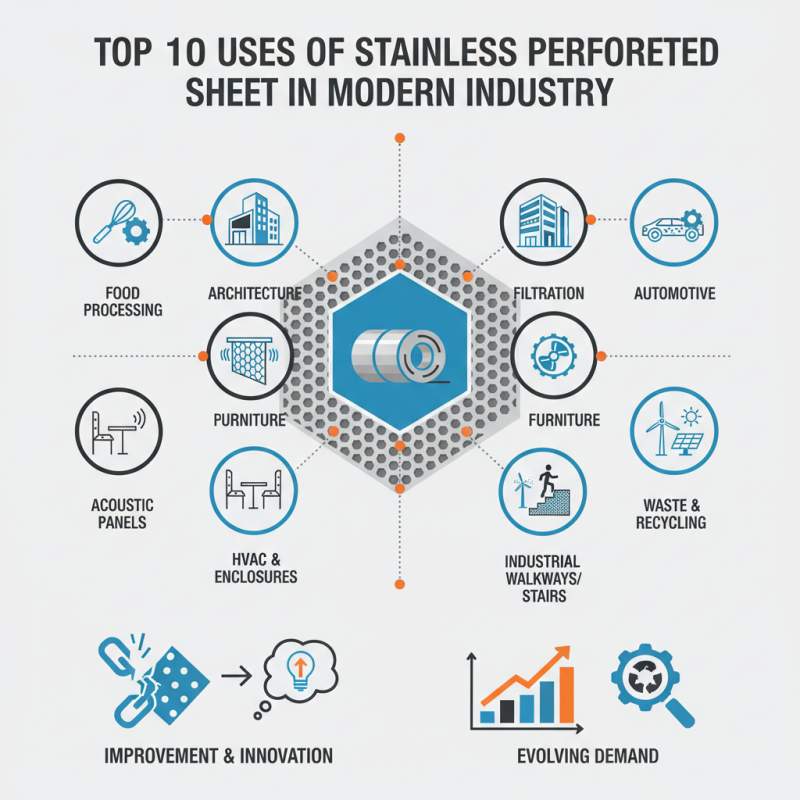

In the realm of modern industry, the versatility of the Stainless Perforated Sheet has gained significant recognition. Its unique characteristics make it invaluable for various applications. These sheets are made from durable stainless steel, providing strength and resistance to corrosion. This makes them an ideal choice for industries that require long-lasting materials.

Consider the food industry, where hygiene is crucial. Stainless Perforated Sheets are used in equipment, ensuring safety and cleanliness. In construction, they provide both support and aesthetic appeal. However, not all sheets are designed equally. Some may lack the desired durability or finish, leading to potential issues. Reflections on these shortcomings can guide improvements.

The applications of Stainless Perforated Sheets extend into filtration, architecture, and automotive sectors. Each use showcases their functionality and practicality. As industries evolve, the demand for innovative solutions continues to grow. Recognizing the imperfections in current offerings presents opportunities for advancement. This makes the exploration of their top uses an exciting journey into modern manufacturing.

Stainless perforated sheets are essential in various filtration systems. They serve as effective barriers, allowing liquids or gases to pass while trapping unwanted particles. The sheets come in various hole sizes and patterns, providing flexibility for specific filtration needs. This versatility is crucial in industries like water treatment, pharmaceuticals, and food processing.

In water filtration, stainless perforated sheets help remove sediments and contaminants. They support the filtration process while ensuring durability against corrosive substances. For example, in food processing, these sheets help maintain hygiene standards. Their smooth surface is easy to clean, reducing the risk of bacterial growth.

However, the design process can be complex. Engineers must carefully choose hole sizes and layouts. Small errors can lead to inefficiencies in filtration. Testing and adjusting are vital steps. Achieving optimal performance requires careful consideration of the material and design. Despite these challenges, the benefits of using stainless perforated sheets in filtration are significant.

Stainless perforated sheets have become a staple in architectural design. Their versatility is unmatched, providing both functionality and aesthetic appeal. These sheets are often used in facades, sunshades, and decorative elements. The ability to customize perforation patterns adds unique character to buildings. Architectures now embrace these designs for their innovative looks.

A recent industry report indicated that the demand for decorative stainless perforated sheets is growing annually by 5%. These sheets not only enhance visual appeal but also improve energy efficiency. They allow natural light while reducing heat gain. This balance captivates architects and designers alike.

Tip: Consider light play when selecting perforation patterns. Different designs can create striking visual effects with changing daylight.

Additionally, stainless perforated sheets are sustainable. They require low maintenance and have a long lifespan, which aligns with eco-friendly building practices. Reflecting on the misuse of these materials, some designs may overcrowd a space, distracting from structural beauty. Achieving harmony is key.

Tip: Always evaluate space and context when choosing design elements. Simplicity often leads to elegance.

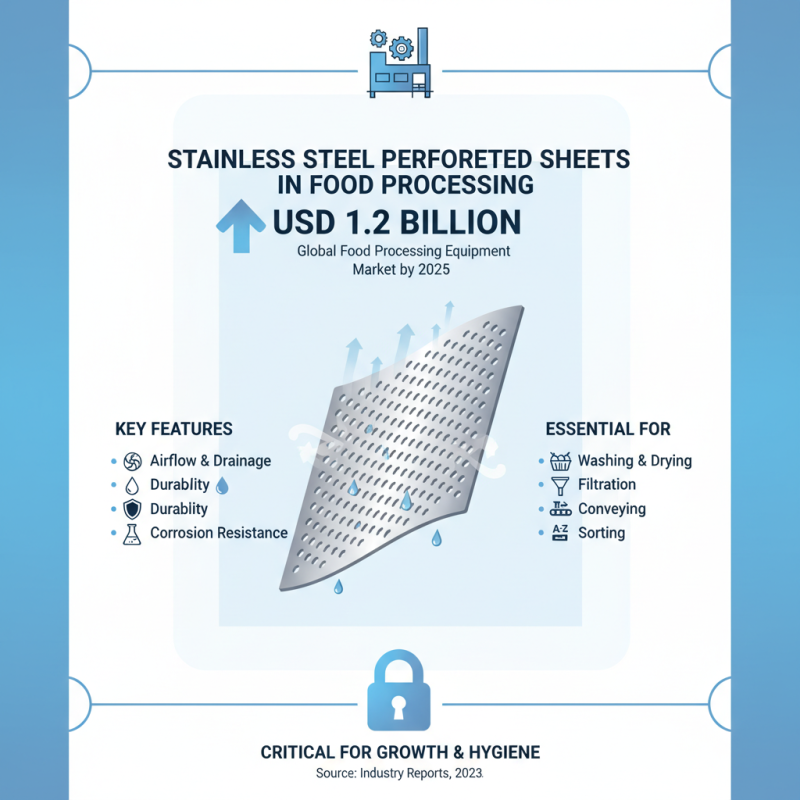

Stainless perforated sheets play a vital role in food processing equipment. Their design features holes that allow for airflow and drainage, making them essential for various applications. According to industry reports, the global food processing equipment market is projected to reach USD 1.2 billion by 2025. In this growth, the use of stainless steel is critical due to its durability and resistance to corrosion.

Many food processing machines utilize these perforated sheets. They ensure hygiene and prevent contamination. For instance, when frying or steaming food, these sheets help with heat distribution, enhancing cooking efficiency. Moreover, they come in various hole sizes, catering to different processing needs. However, not all holes are created equal. Selecting the wrong size can lead to inefficiencies or product loss.

Tips: Always consider the specific requirements of your machinery. Evaluate the material's thickness and hole pattern before making a decision. Small adjustments can lead to better performance. Remember that maintenance is crucial. Regularly inspecting for wear and tear can prevent costly downtimes. It's advisable to keep clean records of your equipment’s performance to spot any unusual trends.

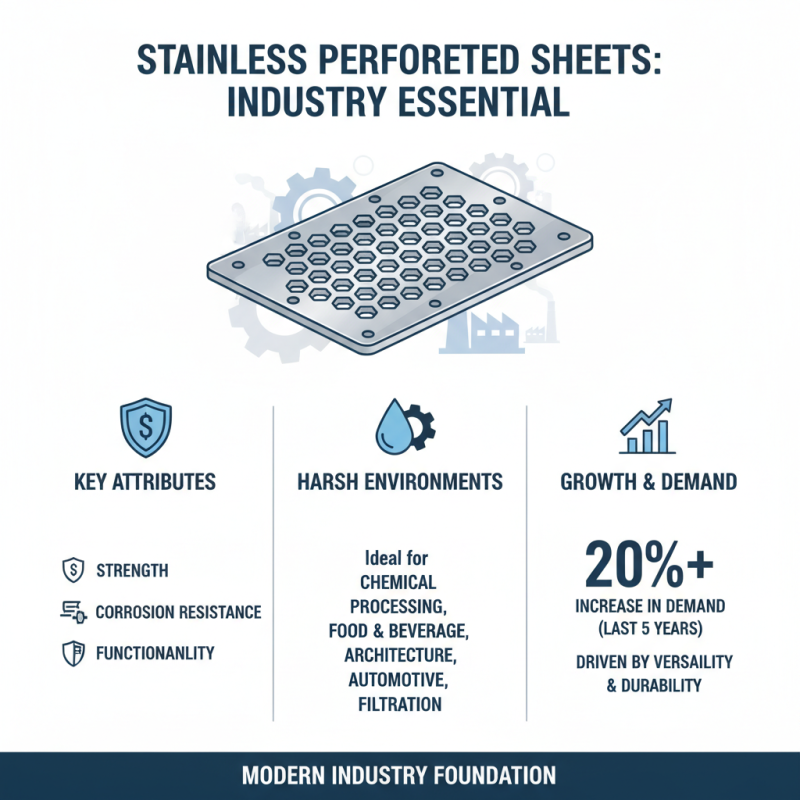

Stainless perforated sheets play a vital role in modern industry. These sheets are valued for their strength and functionality. Their corrosion resistance makes them ideal for harsh environments. According to recent industry data, the demand for stainless perforated sheets has increased by over 20% in the last five years. This growth reflects their importance in various applications.

One of the significant advantages is their lightweight nature. This feature simplifies installation and transportation. Companies benefit from reduced labor costs and better efficiency. For instance, industries often use these sheets for filtration systems, safety guards, and architectural designs. Their design allows for excellent air and light penetration. Yet, not all perforated sheets are created equal. Manufacturers must ensure quality to avoid potential failures.

Tip: When selecting a perforated sheet, consider the hole size and pattern based on specific needs. Improper choices can lead to inefficiencies.

Additionally, stainless perforated sheets are recyclable, aligning with sustainability goals. This makes them more attractive to eco-conscious companies. However, one must ensure proper recycling processes are followed. Poor recycling habits can negate their environmental benefits. Be mindful, as not all recycling centers handle stainless steel effectively.

Tip: Regular maintenance checks can prolong the life of these sheets in industrial applications. Address issues before they escalate.

Stainless perforated sheets have become essential in modern electrical and HVAC systems. Their unique design allows for airflow while providing structural support. According to a report by MarketsandMarkets, the global HVAC market is projected to reach $250 billion by 2026. This growth boosts the demand for effective materials like stainless perforated sheets.

These sheets enhance ventilation efficiency. In HVAC systems, they facilitate the flow of air without compromising filtration. This aspect is critical. A study found that proper ventilation can reduce energy consumption by up to 20%. Stainless perforated sheets also resist corrosion, making them durable for harsh environments. They provide functionality and longevity, which is vital in any industrial setup.

Tips: When selecting materials, consider thickness and hole size. These factors will impact airflow and performance. Also, keep in mind that installation can be complex. Ensure that your design aligns with specific system requirements.

Incorporating stainless perforated sheets into electrical installations can also lead to design challenges. Balancing aesthetics and functionality is not easy. Some systems may suffer from limited space, affecting airflow. Regular assessments are necessary to optimize placements. Be aware that improper adjustments may lead to inefficiency.