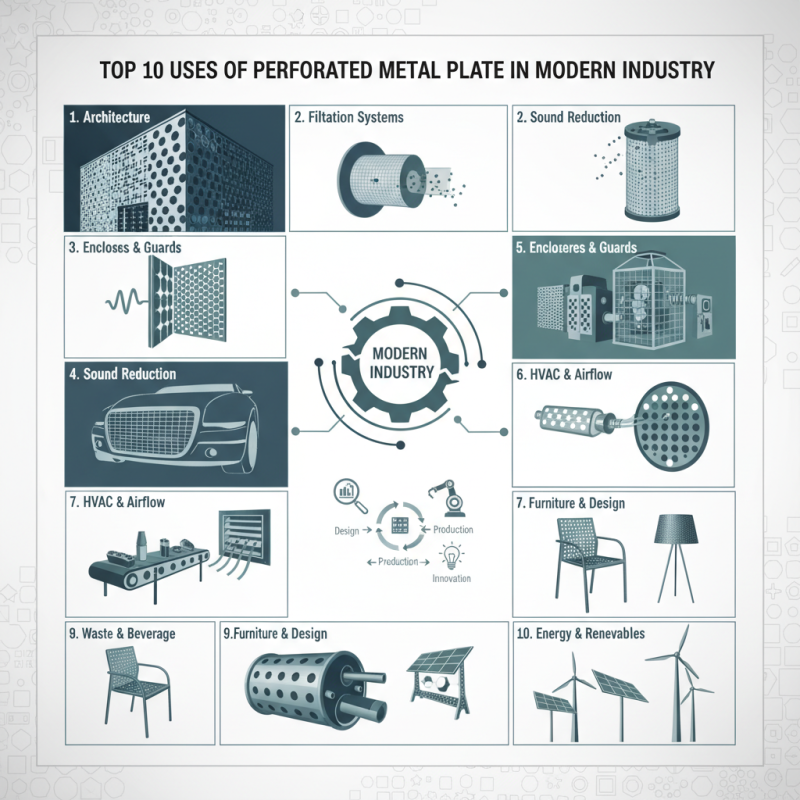

Perforated metal plates have become vital in various industries. Their versatility and functionality make them essential materials for modern applications. Dr. Emily Carter, a leading expert in industrial materials, states, "Perforated metal plates offer unmatched benefits in design and efficiency."

These plates feature a series of holes that provide structural integrity while allowing for airflow and visibility. In architectural designs, they enhance aesthetics and light diffusion. In manufacturing, they play crucial roles in filtration systems and sound reduction. Yet, not every application fully exploits their potential. Designers often overlook specific patterns that could maximize strength or reduce material costs.

Challenges also exist in production. The quality of perforation affects performance. Inadequate techniques may compromise durability or lead to defects. As industries evolve, a deeper understanding of perforated metal plates is essential. Reflection on past applications may unlock new innovations.

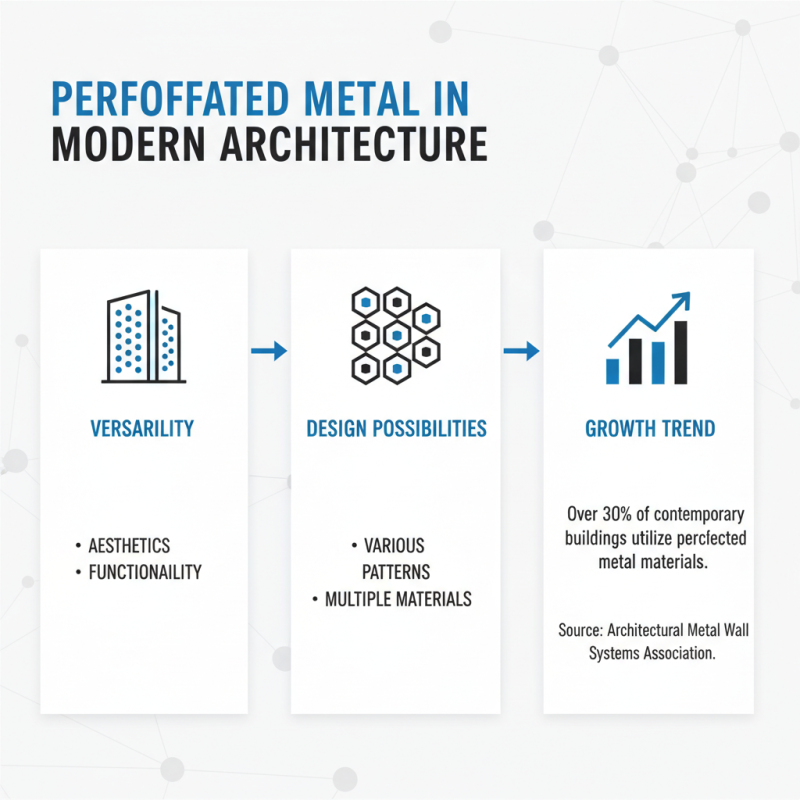

Perforated metal plates have gained traction in modern architecture. Their versatility contributes significantly to both aesthetics and functionality. These plates often come in various patterns and materials, which enhances design possibilities. A report by the Architectural Metal Wall Systems Association indicates that over 30% of contemporary buildings now incorporate perforated materials. This trend showcases the importance of innovation in architectural design.

In urban settings, perforated metal plates serve multiple roles. They can be used for facades, privacy screens, and outdoor furniture. The perforation not only allows light and air circulation but also reduces heat absorption. According to recent studies, buildings utilizing these plates can achieve energy savings of about 15%. This is a win-win for both the environment and building operations. However, some architects have faced challenges in balancing aesthetics with functionality, sometimes compromising on one aspect.

Moreover, implementing perforated metal in design doesn’t come without its concerns. Maintenance can be tricky, especially in high-traffic areas. Accumulation of dirt can detract from the visual appeal. Additionally, correct selection of hole patterns is crucial. Poor choices can lead to undesirable structural weaknesses. Designers must weigh these factors carefully when integrating perforated materials into their projects, ensuring a holistic approach to modern architecture.

Perforated metal plates play a crucial role in industrial filtration systems. They provide both strength and versatility. Often made from materials like stainless steel or aluminum, these plates are designed with precise holes. This design allows for effective separation of particles from liquids or gases. According to industry reports, using perforated metal can enhance the filtration process by up to 30% compared to traditional methods.

In environmental filtration applications, perforated plates contribute significantly to water purification. They allow water to flow while capturing contaminants. This is crucial for industries relying on clean water for production. Interestingly, some studies suggest that the efficiency of these systems can diminish over time if maintenance is neglected. Regular checks are essential to ensure optimal performance.

Moreover, perforated plates are used in air filtration systems to capture dust and pollutants. In industrial settings, they can reduce airborne particles significantly. Data reveals that systems using these plates can achieve a 50% reduction in particulate matter. However, the effectiveness may decrease with increased buildup on the plate surface. Thus, periodic cleaning is important to maintain their efficacy and extend their lifespan.

Perforated metal plates play a significant role in sound absorption and acoustics across various industries. These plates feature numerous holes, allowing sound waves to pass through. This unique design reduces noise pollution in crowded environments. According to a report by the International Journal of Acoustics and Vibration, perforated panels can absorb up to 60% of sound energy when strategically placed.

In industrial settings, their application can be seen in manufacturing plants and commercial buildings. They help control reverberation and provide a more pleasant auditory space. When installed in walls or ceilings, these panels can significantly diminish echo effects. However, achieving optimal performance often requires careful design and placement, a task that is not always straightforward.

A study published in the Journal of Building Acoustics highlights the importance of customizing perforation patterns. Depending on factors like hole size and spacing, the effectiveness can vary widely. Inadequate design may lead to unexpected acoustic issues. Thus, collaboration with acoustics experts becomes critical for achieving the desired results.

This bar chart illustrates the various applications of perforated metal plates across different industries, showcasing their crucial role in sound absorption and acoustics.

Perforated metal plates play a vital role in automotive manufacturing and parts production. Utilizing lightweight materials can reduce vehicle weight, improving fuel efficiency. Data shows that a reduction of even 10% in weight can enhance fuel economy by up to 5%. This change is essential for meeting increasingly strict emissions standards.

The versatility of perforated metal allows for innovative designs in car components. These plates can be used in exhaust systems and engine covers, aiding in heat dissipation. Reports indicate that perforated designs improve structural integrity while decreasing material usage. This fact leads to a potential 15% reduction in production costs.

However, there are challenges. Creating custom perforated patterns takes time and precise engineering. Some manufacturers struggle with balancing performance and cost. Ensuring quality control during the production of perforated parts is also difficult. The automotive industry must reflect on these issues to fully leverage the benefits of perforated metal.

| Application | Industry | Functionality | Material Used |

|---|---|---|---|

| Automotive Grilles | Automotive | Airflow and Aesthetic Design | Aluminum, Steel |

| Sound Deadening Panels | Automotive | Noise Reduction | Steel, Stainless Steel |

| Weight Reduction Components | Automotive | Lower Overall Weight | Aluminum |

| Screens for Radiators | Automotive | Protection Against Debris | Stainless Steel |

| Exhaust System Parts | Automotive | Heat Resistance and Noise Control | Stainless Steel |

| Interior Trim | Automotive | Aesthetic Appeal | Aluminum, Plastic Coating |

| Protective Mesh Covers | Automotive | Defense Against Small Objects | Steel |

| Battery Holder Frames | Automotive | Secure Battery Placement | Aluminum |

| Lighting Fixtures | Automotive | Illumination Aids | Aluminum, Steel |

| Ventilation Grids | Automotive | Airflow Management | Steel |

Perforated metal plates have found significant applications in food processing and packaging. Their unique design allows for optimal airflow while maintaining structural integrity. This feature is particularly beneficial in drying processes. For instance, fruits and vegetables can be dried uniformly, enhancing quality and flavor. The perforations facilitate even heat distribution, which is essential in achieving desired moisture levels.

In packaging, perforated metal sheets are used to create breathable containers. These containers help prolong the shelf life of food products. They allow gas exchange, which prevents spoilage. However, manufacturers must be cautious. If the perforations are too large, they may expose food to contaminants. It's a delicate balance that requires careful consideration.

This material also plays a vital role in filtration systems within food processing plants. Custom-designed perforations allow for efficient separation of unwanted particles. Nonetheless, the need for regular maintenance and cleaning cannot be overlooked. Over time, debris can accumulate, affecting performance. Thus, while perforated metal is innovative, users must remain vigilant to ensure optimal operation and food safety.