When embarking on a project that requires the use of a Perforated Copper Sheet, making the right choice is crucial for achieving the desired outcome. According to industry expert Dr. Emily Carter, a metallurgical engineer with over 20 years of experience, "The key to selecting the perfect perforated copper sheet lies in understanding both the specifications of your project and the unique properties of copper." This statement emphasizes the importance of combining technical knowledge with material characteristics to optimize performance.

Copper's versatility and aesthetic appeal make it a favored choice across various industries, from architectural applications to decorative elements. However, with numerous options available on the market, it can be overwhelming to determine which perforated sheet best suits your needs. Factors such as hole size, pattern, thickness, and finish play a significant role in influencing both functionality and visual impact. To navigate these considerations effectively, understanding the specific requirements of your project is essential. In this guide, we will outline the top ten tips for selecting the best Perforated Copper Sheet, ensuring that your project not only meets but exceeds your expectations.

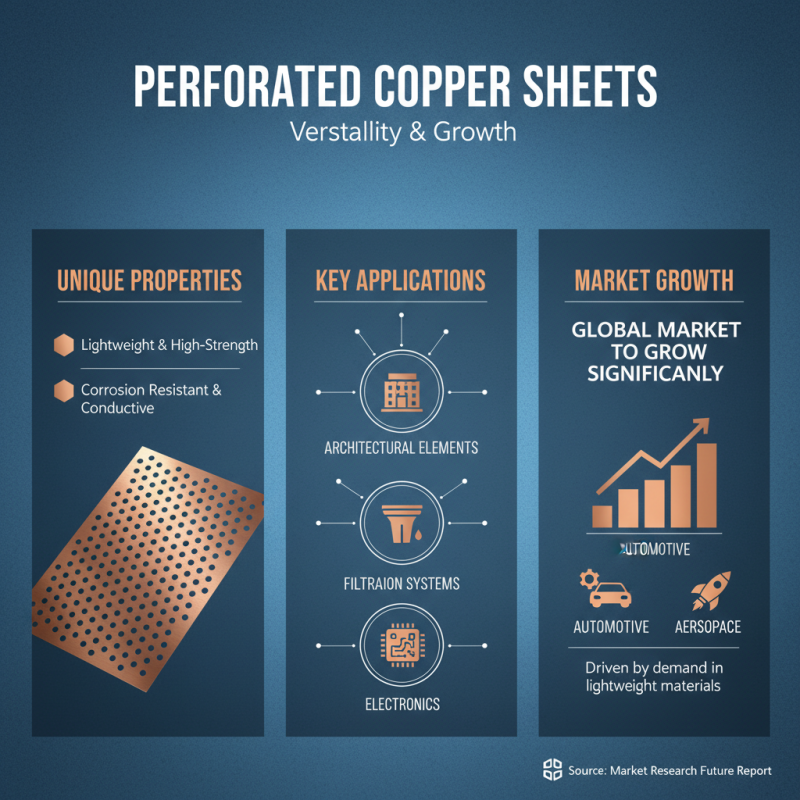

Perforated copper sheets have gained popularity across various industries due to their unique properties and versatility. These sheets are often used in architectural elements, filtration systems, and electronics, making them essential in modern construction and manufacturing. According to a report by Market Research Future, the global market for metal perforations is expected to grow significantly, driven by rising demands in the automotive and aerospace sectors, where lightweight and high-strength materials are crucial.

When selecting the best perforated copper sheet for your project, it is vital to consider the intended application. For instance, if you plan to use the sheet in a filtration system, make sure to assess the hole size and pitch to ensure optimal flow and filtration efficiency. A report from the American Institute of Steel Construction notes that proper perforation design can enhance the mechanical properties of the copper, leading to better performance under various conditions.

Another critical factor to take into account is the thickness of the copper sheet. Thicker sheets provide more durability and resistance to wear, which is essential in environments exposed to harsh conditions. Proper advice from experts in the industry often emphasizes that balancing the material’s weight and strength can lead to more cost-effective solutions.

When selecting perforated copper sheets for your project, several key factors must be considered to ensure you make the best choice. First, the intended application greatly influences the material specifications. For example, perforated copper sheets are widely utilized in architectural applications, thermal management, and electronic equipment, where heat dissipation and conductivity are critical. Industry reports indicate that the demand for perforated metals, including copper, is expected to grow at a CAGR of 5.2% from 2023 to 2030. This increasing utilization highlights the importance of selecting sheets that meet your specific performance requirements.

One tip for selecting the best perforated copper sheets is to pay attention to the hole size and pattern. The hole diameter, spacing, and overall pattern can impact not only aesthetics but also functionality, such as airflow and light penetration. For instance, a study published by the Metal Research Institute found that optimal perforation configurations can enhance heat transfer efficiency by up to 25%, making appropriate hole choices vital for projects requiring thermal management.

Additionally, consider the thickness and finish of the copper sheet. Thicker sheets typically provide greater durability and structural integrity, while surface treatments can significantly affect corrosion resistance and appearance. Per industry standards, the gauge of the sheet should align with specific load-bearing requirements to prevent deformation during use. By focusing on these essential factors, you can ensure that the perforated copper sheet you choose is the ideal fit for your project's needs.

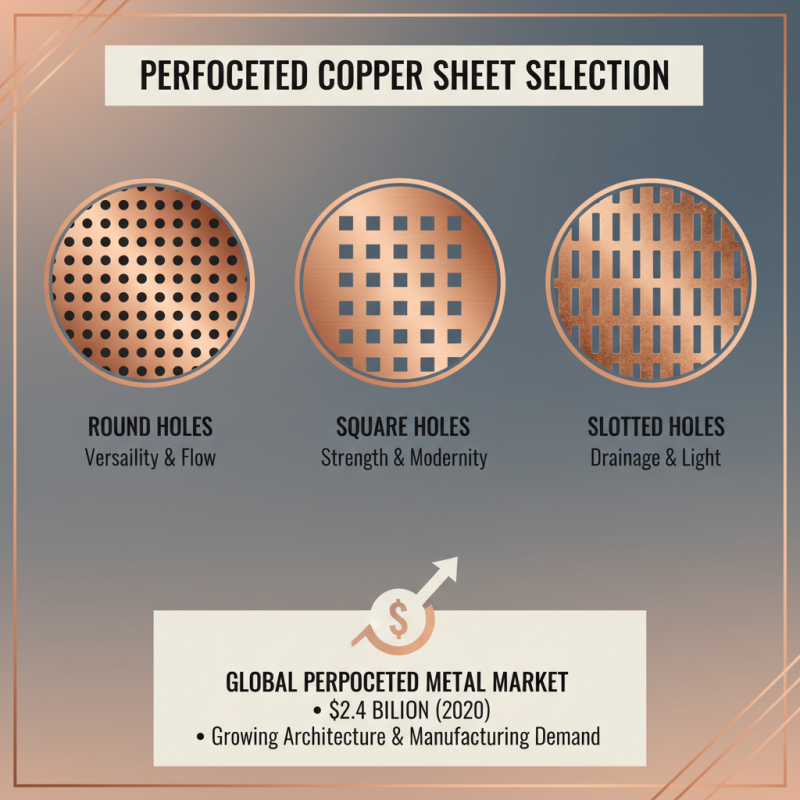

When selecting a perforated copper sheet for your project, one crucial consideration is the hole pattern. The arrangement and size of these holes significantly impact both the functionality and aesthetics of the copper sheet, making it essential to evaluate the various options available. According to a report by Grand View Research, the global perforated metal market was valued at approximately $2.4 billion in 2020 and is projected to expand further, driven by increased demand across multiple industries, including architecture and manufacturing.

Different hole patterns, such as round, square, and slotted, cater to diverse applications and preferences. Round holes, for instance, are often employed for ventilation and filtration purposes, while square holes may offer a more rigid structure beneficial in load-bearing applications. Recent studies indicate that architects and engineers frequently choose specific hole patterns based on not only functional requirements but also aesthetic appeal. For example, a 2021 survey reported that 67% of professionals in the construction sector prefer custom hole layouts to enhance their project designs, highlighting the evolving needs of industries that utilize perforated materials.

Furthermore, the spacing between holes, known as pitch, is another essential factor to consider. A tighter pitch can increase structural integrity and strength, making it suited for harsh environments, whereas a wider pitch may be preferable for applications requiring more light or airflow. Research shows that a well-chosen hole pattern can contribute to reduced material costs by optimizing the use of copper without compromising durability, which is vital in today’s resource-conscious economy. Thus, careful evaluation of hole patterns can lead to more effective project outcomes while maximizing the benefits of perforated copper sheets.

When selecting the best perforated copper sheet for your project, one of the most critical factors to consider is the material’s thickness and weight. The thickness of the copper sheet affects not only its durability but also its ability to withstand various forms of stress, including bending and impact. A thicker sheet generally offers better resistance to deformation, making it suitable for applications that require structural integrity, such as architectural elements or industrial components. However, it's essential to strike a balance, as an overly thick sheet may add unnecessary weight to your project, complicating installation and handling.

Weight is another crucial consideration, especially in applications where mounting and support structures play a significant role. A lighter perforated copper sheet can facilitate more straightforward installation and reduce the load on supporting frameworks. Understanding the specific demands of your project can guide you in choosing a sheet that optimally balances thickness and weight. For instance, if your project requires frequent mobility or repositioning, a lightweight option may be more advantageous.

Therefore, assessing both thickness and weight in relation to your project requirements will help ensure optimal performance and longevity of the selected material.

When it comes to budgeting for your perforated copper sheet projects, understanding the factors that influence pricing is crucial. According to a recent report from the Copper Development Association, the cost of copper has fluctuated between $3.50 to $4.50 per pound over the past year due to market demands and global supply chain disruptions. This variability means that project managers need to closely monitor market conditions and plan their finances accordingly. Estimating total costs should not only include material prices but also factors such as shipping fees, cutting services, and potential wastage during fabrication.

Sourcing high-quality perforated copper sheets requires a strategic approach. Engaging with reputable suppliers who specialize in metal fabrication can yield better deals and higher quality materials. Industry analysis from MetalMiner suggests that networking with suppliers at trade shows or industry conferences can provide access to bulk purchasing discounts and updated pricing trends. Additionally, considering local suppliers may save on transportation costs and lead times, allowing for a more efficient procurement process. By being informed about market dynamics and establishing solid relationships with suppliers, you can make more effective budgetary decisions that align with your project requirements.

| Tip No. | Tip Description | Key Considerations | Estimated Cost (per sq ft) |

|---|---|---|---|

| 1 | Determine Your Thickness Needs | Consider durability and application. | $5.00 - $15.00 |

| 2 | Choose the Right Hole Size and Pattern | Impact on appearance and functionality. | $4.00 - $12.00 |

| 3 | Consider Corrosion Resistance | Environment and exposure factors. | $6.00 - $15.00 |

| 4 | Evaluate Sheet Size | Maximize material use and minimize waste. | $5.50 - $14.00 |

| 5 | Research Supplier Credibility | Check reviews and ratings. | N/A |

| 6 | Request Samples | Evaluate quality firsthand. | N/A |

| 7 | Compare Pricing Across Suppliers | Get the best deal. | $5.00 - $13.00 |

| 8 | Consider Customization Options | Personalize for specific requirements. | $7.00 - $16.00 |

| 9 | Understand Delivery Times | Plan for project timelines accordingly. | N/A |

| 10 | Check Return Policies | Essential for ensuring satisfaction. | N/A |