The selection of the right materials is crucial for the success of any project, and when it comes to choosing the appropriate Stainless Steel Perforated Sheet, the decision can significantly impact both functionality and aesthetics. According to a report from the Global Stainless Steel Market, the demand for stainless steel products, particularly perforated sheets, has risen steadily, with an annual growth rate projected at 5.7% through 2027. This is largely due to their versatility in applications ranging from architectural designs to automotive components. As projects increasingly require materials that offer durability, corrosion resistance, and aesthetic appeal, understanding the specifications, types, and benefits of Stainless Steel Perforated Sheets becomes essential. In this guide, we will explore key factors to consider in selecting the best perforated sheet to meet your project needs effectively.

When choosing stainless steel perforated sheets for your project, several critical factors must be considered to ensure optimal performance and durability. First, the material grade is fundamental. For instance, 304 stainless steel is often used for its excellent corrosion resistance and formability, making it a popular choice for both indoor and outdoor applications. According to the International Stainless Steel Forum, approximately 50% of stainless steel produced globally is of grade 304, emphasizing its reliability and widespread use in various industries.

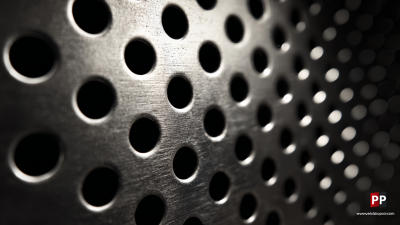

Additionally, the hole pattern and size play a significant role in determining the functionality of the perforated sheet. The pitch and percentage of open area affect not just aesthetic appeal but also performance characteristics. A report by the Metal Industries Association shows that a well-designed perforated sheet can enhance airflow by up to 25%, making it ideal for applications in HVAC systems and industrial filters. Undertaking careful consideration of these factors, such as load-bearing capabilities and environmental conditions, is essential in selecting the right stainless steel perforated sheet for specific project needs.

When selecting the best stainless steel perforated sheet for your project, understanding the different grades of stainless steel is crucial. Each grade offers unique properties that cater to various applications. For instance, 304 stainless steel, known for its excellent corrosion resistance and formability, is widely used in kitchen equipment, food processing, and chemical applications. Its versatility makes it an ideal choice for many projects, balancing affordability and performance.

On the other hand, 316 stainless steel stands out in environments that require heightened resistance to corrosion, particularly those containing chlorides, like marine applications. This grade is often employed in chemical processing equipment and medical devices, where durability and hygiene are vital. By recognizing the characteristics of different stainless steel grades, you can ensure that the chosen perforated sheet not only meets the aesthetic requirements of your design but also performs effectively under the specific conditions of its intended use.

When selecting a stainless steel perforated sheet for your project, the hole size and pattern play a crucial role in determining both performance and aesthetics. For instance, recent studies have shown that varying perforation patterns significantly affect the load-carrying capacity and the capability-to-weight ratio of cold-formed steel cantilever beams. In engineering assessments, it was found that specific hole configurations can enhance structural integrity while reducing material usage, making them a preferred choice for sustainable design.

When selecting a stainless steel perforated sheet for your project, the hole size and pattern play a crucial role in determining both performance and aesthetics. For instance, recent studies have shown that varying perforation patterns significantly affect the load-carrying capacity and the capability-to-weight ratio of cold-formed steel cantilever beams. In engineering assessments, it was found that specific hole configurations can enhance structural integrity while reducing material usage, making them a preferred choice for sustainable design.

Furthermore, the pattern of perforations can influence daylighting and visual comfort in architectural applications. Research indicates that non-uniform perforated solar screens outperform uniform ones in terms of natural light diffusion, achieving superior daylighting with the same perforation ratios. Patterns such as periphery-center and bottom-top are particularly effective in maximizing light entry while maintaining aesthetic appeal. By thoughtfully aligning hole size and arrangement with project goals, architects can create facades that successfully merge function and design, contributing to a contemporary architectural landscape that values both utility and visual impact.

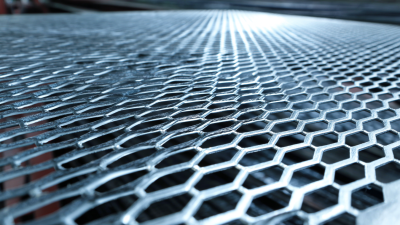

When selecting a stainless steel perforated sheet for your project, understanding the comparative analysis of thickness and durability is crucial. The thickness of the sheet directly influences its strength and flexibility. Thicker sheets, while offering greater durability, may be more challenging to work with and could require specialized tools for cutting and shaping. A gauged approach to thickness is essential, as a balance must be struck between the strength needed for the application and the ease of installation.

Durability, on the other hand, is determined by both the material properties and the design of the perforations. For instance, a sheet with a higher percentage of open area can provide excellent ventilation and drainage while maintaining structural integrity. However, this can also impact the overall strength of the sheet. It's important to consider the specific environmental conditions the sheet will face, such as exposure to corrosive substances or extreme temperatures, to ensure the chosen material will sustain its performance over time. Ultimately, assessing these factors will lead to a selection that fulfills both functional requirements and longevity.

| Thickness (mm) | Hole Size (mm) | Open Area (%) | Material Grade | Durability Rating |

|---|---|---|---|---|

| 0.5 | 2.0 | 40 | 304 | Moderate |

| 1.0 | 3.0 | 50 | 316 | High |

| 1.5 | 4.0 | 60 | 430 | Low |

| 2.0 | 5.0 | 70 | 304 | Very High |

| 2.5 | 6.0 | 80 | 316 | Extreme |

When embarking on a mobile app development project in 2025, understanding the cost factors and budgeting strategies is crucial for achieving the right balance between quality and affordability. One of the primary considerations is the complexity of the app. More sophisticated functionalities typically demand advanced skills and longer development timelines, which directly correlate with increased costs. Therefore, defining the essential features early in the planning phase can help streamline the process and prevent budget overruns.

Additionally, the choice of development platforms and technologies can significantly affect project expenses. Opting for cross-platform solutions may seem cost-effective initially, but it is essential to evaluate their long-term performance and maintenance implications. Adequate budget allocation for ongoing support and updates can mitigate future complexities and ensure that the app remains relevant in a fast-evolving digital landscape. By carefully analyzing these factors, project managers can effectively maintain quality while keeping their budgets intact.