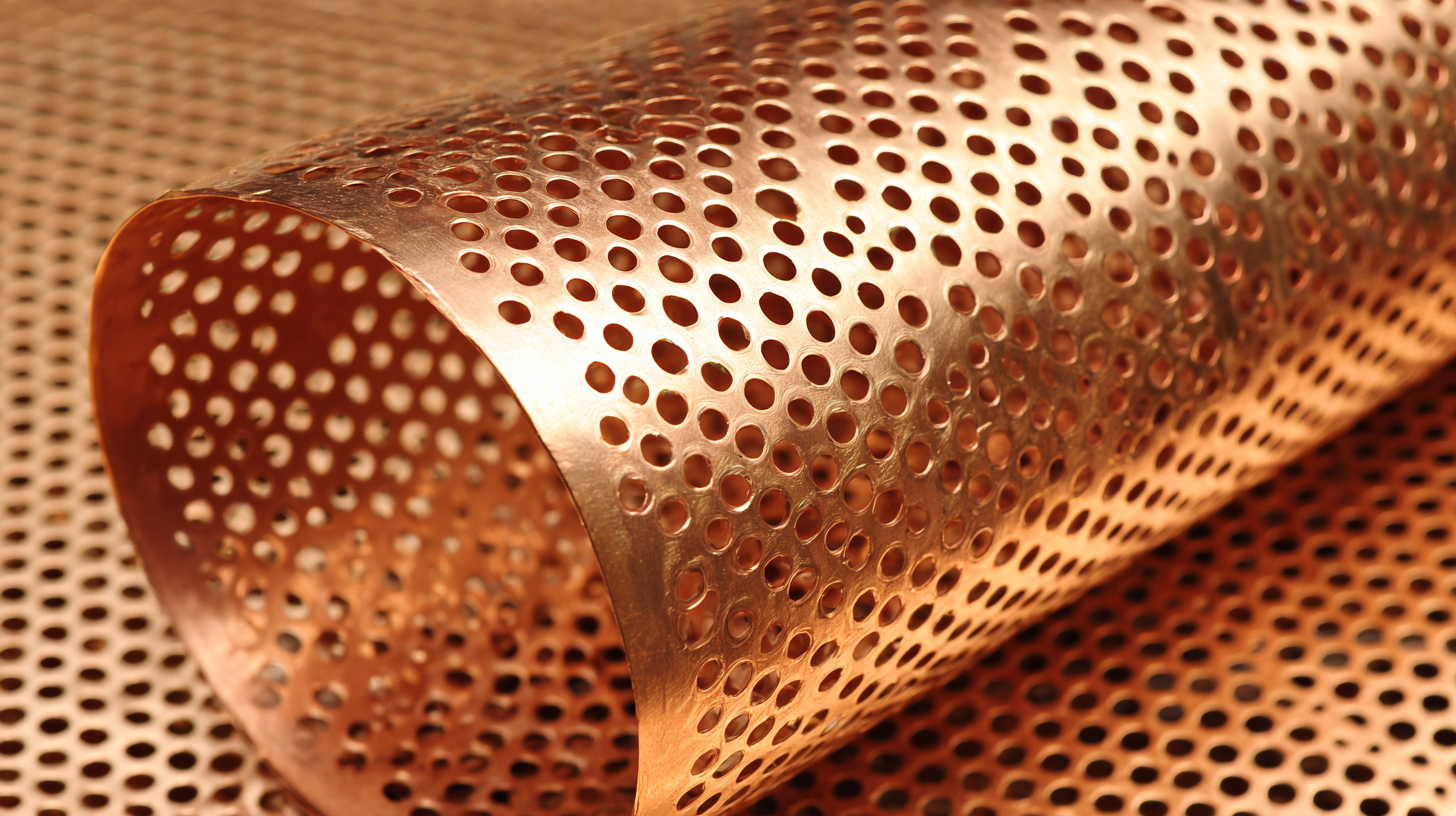

Selecting the right perforated copper sheet for your project is essential to ensuring optimal performance and aesthetic appeal. Perforated copper sheets are widely used in various industries, ranging from architecture to electronics, due to their unique combination of durability, flexibility, and conductivity. However, with a myriad of options available on the market, choosing the appropriate sheet can be a daunting task.

This guide aims to simplify the selection process by focusing on key technical specifications that influence the functionality and suitability of perforated copper sheets for specific applications. By understanding factors such as hole size, sheet thickness, and the pattern of perforation, you can make an informed decision that meets both your project's requirements and your desired aesthetic.

Whether you are looking to enhance sound absorption, reduce weight, or improve air flow, this detailed overview will provide the insights necessary to select the ideal perforated copper sheet for your needs.

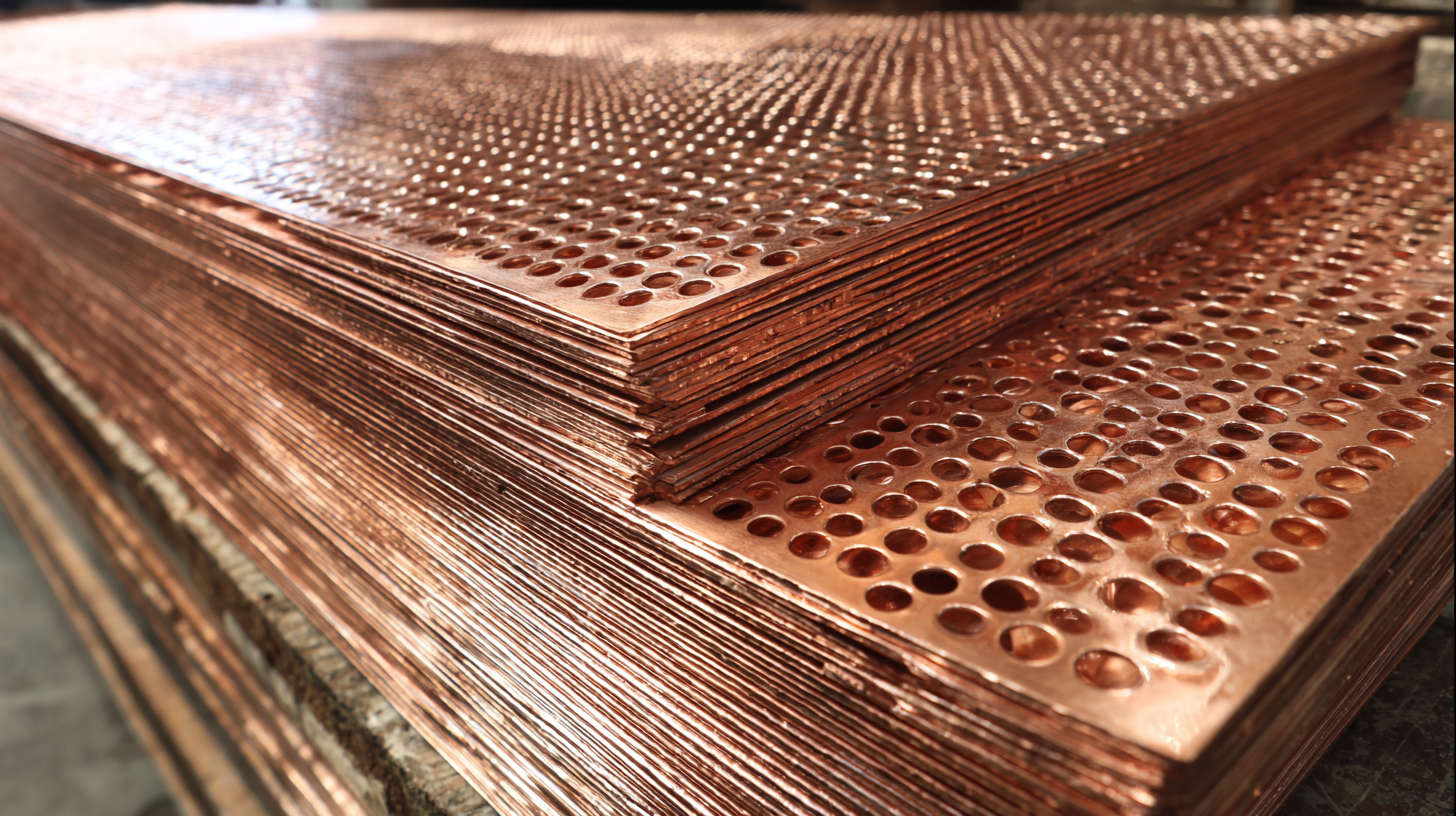

When selecting the appropriate perforated copper sheet for your project, the thickness of the sheet is a crucial factor that influences both functionality and durability. Thicker sheets generally offer greater strength, making them ideal for applications where structural integrity is paramount, such as in architectural designs or heavy-duty machinery components. However, heavier materials may not be suitable for all projects, particularly where flexibility or weight is a concern. Therefore, carefully assessing the requirements of your application is essential.

In addition to strength, the thickness of the perforated copper sheet affects the sheet's ability to conduct heat and electricity. For projects involving thermal management or electrical applications, optimizing the thickness to ensure efficient performance is critical. Moreover, the specific perforation pattern—combined with the selected thickness—can alter airflow and sound absorption characteristics, making it vital to consider how these parameters interact depending on the intended use. Ultimately, striking the right balance between thickness, performance, and project requirements ensures successful outcomes in applications utilizing perforated copper sheets.

| Thickness (mm) | Hole Diameter (mm) | Percentage of Open Area (%) | Material Grade | Typical Applications |

|---|---|---|---|---|

| 0.5 | 2.0 | 35 | C11000 | Indoor decorative applications |

| 1.0 | 3.0 | 40 | C11000 | Air handling systems |

| 1.5 | 4.0 | 45 | C11000 | Architectural features |

| 2.0 | 5.0 | 50 | C11000 | Marine applications |

| 3.0 | 6.0 | 55 | C11000 | Industrial applications |

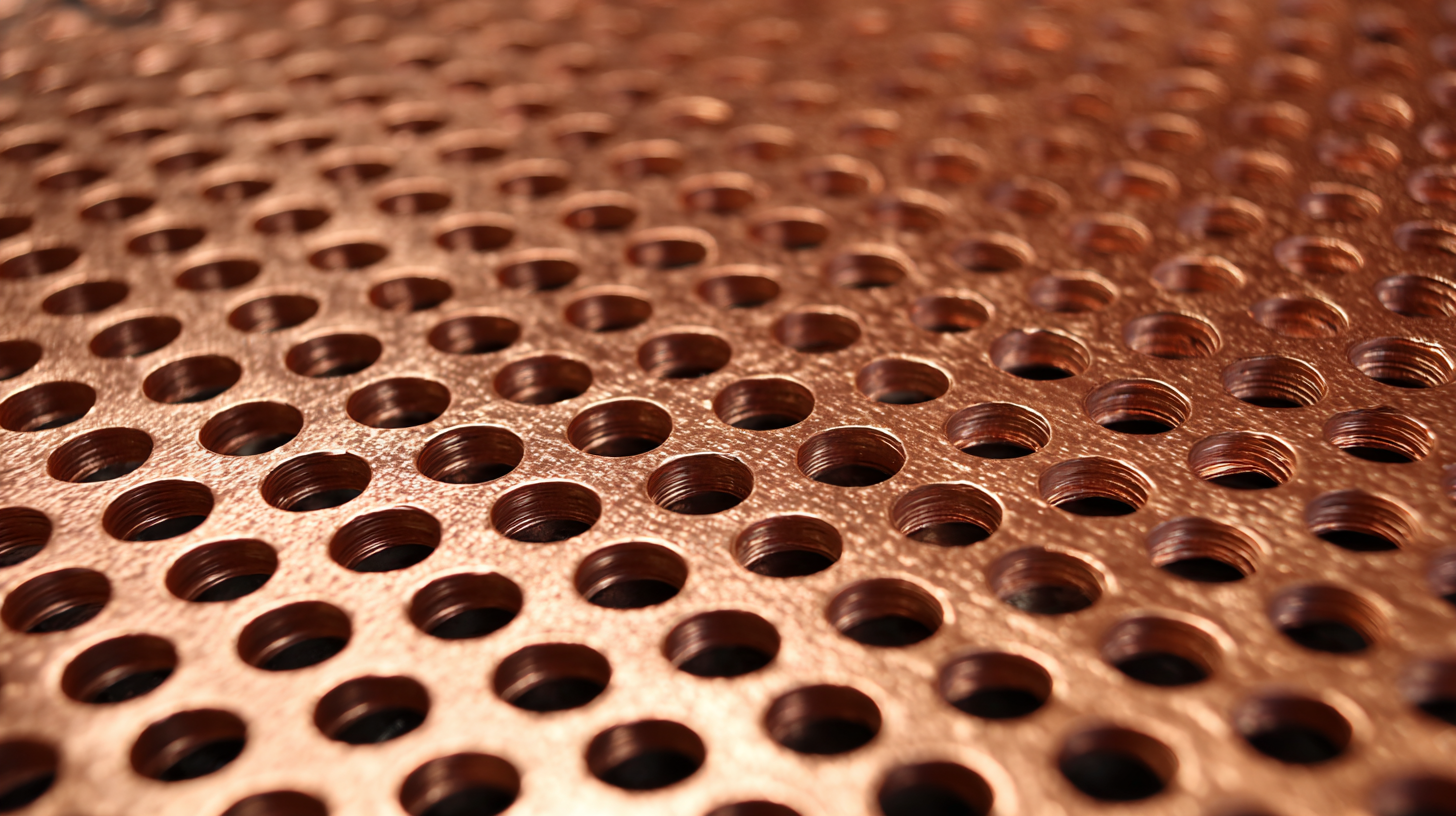

When selecting a perforated copper sheet for your project, understanding the significance of hole size and pattern is crucial for achieving optimal performance. The hole size directly affects airflow, drainage, and structural integrity. For instance, studies reveal that a reduction in hole diameter can lead to a significant increase in material strength and durability, particularly in applications requiring high resistance to wear and impact. A common optimal hole size for various applications ranges from 1mm to 15mm, depending on the specific requirements of the project.

In addition to hole size, the hole pattern plays an essential role in the sheet's functionality. A staggered pattern can enhance the sheet’s aesthetic appeal while improving strength distribution. According to a report from the Copper Development Association, perforated sheets featuring a staggered hole pattern can improve material stiffness by up to 20% compared to linear patterns.

**Tips:** When choosing a perforated copper sheet, consider both your mechanical needs and aesthetic preferences. Always cross-reference the specific performance data for the chosen hole sizes and patterns with industry standards to ensure compatibility with your project. Additionally, consulting a supplier's technical specifications can provide valuable insights tailored to your application’s needs.

This chart illustrates the air flow efficiency of different perforated copper sheets based on hole size. As the hole size increases, the air flow efficiency generally improves, reaching a peak at 4mm, before slightly declining at 5mm.

When selecting a perforated copper sheet for your project, understanding the metal alloy composition is crucial as it significantly influences the material's durability and corrosion resistance. Copper alloys, such as brass or bronze, each possess unique properties that affect their suitability for various applications. For instance, alloys with higher zinc content tend to exhibit improved strength and resistance to wear, making them ideal for projects that demand high durability. Conversely, pure copper excels in conductivity and malleability but may require additional protective coatings to ensure longevity in corrosive environments.

When selecting a perforated copper sheet for your project, understanding the metal alloy composition is crucial as it significantly influences the material's durability and corrosion resistance. Copper alloys, such as brass or bronze, each possess unique properties that affect their suitability for various applications. For instance, alloys with higher zinc content tend to exhibit improved strength and resistance to wear, making them ideal for projects that demand high durability. Conversely, pure copper excels in conductivity and malleability but may require additional protective coatings to ensure longevity in corrosive environments.

Corrosion resistance is another vital aspect driven by alloy composition. The presence of elements like nickel or tin can enhance stability and resistance to oxidation, which is particularly important in humid or salt-laden atmospheres. When evaluating which perforated copper sheet to use, it's essential to consider the environmental conditions it will face. Assessing these specifications will help ensure the selected material not only meets aesthetic and functional requirements but also withstands the test of time, minimizing maintenance and replacement costs in the future.

When selecting a perforated copper sheet, understanding the perforation percentage is crucial for meeting both functional and aesthetic demands. The perforation percentage determines the amount of open area in the sheet, which directly impacts fluid flow and the material's visual appearance. For projects requiring high airflow, such as ventilation systems or decorative screens, a higher perforation percentage is ideal. This ensures that air or liquids can pass through efficiently, reducing resistance and increasing performance.

On the other hand, aesthetic considerations may lead to a preference for lower perforation percentages, creating a more solid appearance while still allowing for some degree of openness. This balance between visibility and functionality is essential, especially in design-driven applications such as architectural facades or interior elements. When assessing perforation patterns, it's also important to consider the shape, size, and distribution of the holes, as these factors contribute significantly to the overall visual appeal. Thus, the right choice of perforation percentage not only fulfills operational requirements but also enhances the aesthetic value of the project.

When selecting a perforated copper sheet for your project, understanding the comparative manufacturing techniques is crucial. Traditional techniques often include punching, laser cutting, and water jet cutting. Punching remains the most widely used method due to its efficiency and cost-effectiveness, especially for bulk production. According to industry reports, approximately 65% of perforated metal production utilizes punching techniques, highlighting its dominance in the market.

Conversely, laser cutting provides high precision and the ability to create intricate patterns with less material wastage. This method is increasingly favored in custom applications where detail is paramount. Reports from metalworking associations indicate that the use of laser cutting in perforated sheets has increased by 30% in the past five years due to advancements in technology. Water jet cutting, while less prevalent, offers a unique advantage in processing thicker sheets and avoiding thermal distortions, making it suitable for specialized projects where material integrity is critical. Understanding these manufacturing techniques allows for better selection based on the specific requirements of your project, optimizing both performance and aesthetics in the final product.