In an era of increasing demand for versatile and sustainable building materials, perforated metal screen panels have emerged as a vital solution across various industries. According to a recent market report by Research and Markets, the global perforated metal market is projected to reach USD 2.84 billion by 2025, growing at a CAGR of 5.2% from 2020. This growth is fueled by their applications in architectural designs, noise control, and filtration systems, where not only functionality but aesthetic appeal is essential. Leading manufacturing factories in China are at the forefront of this innovation, providing premium perforated metal screen panels that meet international quality standards. As industries continue to evolve, these panels offer unique properties that balance resilience and design flexibility, making them a preferred material for modern construction and renovation projects.

Premium perforated metal screen panels have become a go-to choice for a range of industrial and architectural applications due to their unique combination of strength, versatility, and aesthetic appeal. According to a recent report from MarketsandMarkets, the global perforated metal market is projected to reach USD 1.27 billion by 2025, reflecting the rising demand driven by sectors such as construction and automotive, where lightweight and durable materials are crucial.

Choosing premium perforated metal screen panels offers several advantages. Their ability to provide airflow while maintaining privacy makes them ideal for projects where ventilation is essential, such as in facades and partition walls. Additionally, these panels are customizable in terms of hole size, shape, and density, allowing architects and designers to achieve specific visual effects and performance criteria. A study by Research and Markets found that 56% of architects prefer using perforated metal for its design flexibility and functional benefits, solidifying its status as a must-have in modern construction.

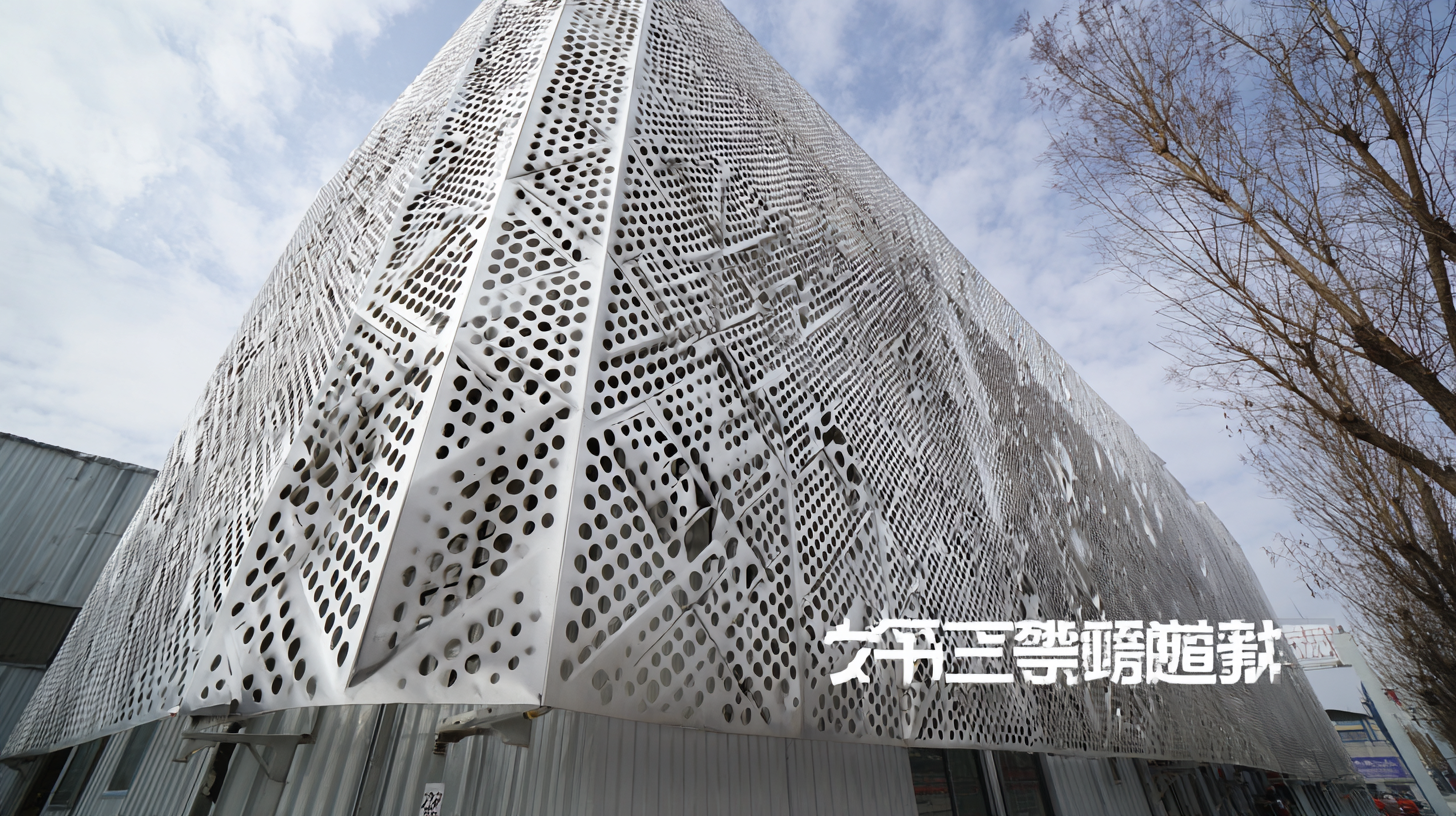

In recent architectural trends, the innovative use of perforated metal screens is transforming modern design by introducing both functionality and aesthetic appeal. A notable example is the residential tower completed by a local architecture studio in Brooklyn, featuring a wavy, perforated-metal facade that adds dynamic movement to the structure. This approach not only enhances visual interest but also allows for light and air to permeate the building, exemplifying how perforated materials can redefine urban aesthetics.

Similarly, the new atrium designed by SHoP Architects showcases the airy quality achievable through the strategic use of perforated elements. By bridging indoor and outdoor spaces, these designs improve the overall ambiance and usability of the environment. This trend reflects a broader movement towards enhancing building facades, as seen in various recent projects that incorporate modern interpretations of traditional architectural concepts, such as the mashrabiya. These adaptations elevate perforated screens from mere structural components to vital contributors of design innovation and cultural symbolism in contemporary architecture.

When sourcing premium perforated metal screen panels, cost-effective strategies are essential for optimizing both quality and budget. One of the most effective methods is to engage directly with manufacturers in China, known for their advanced production capabilities and competitive pricing. By bypassing middlemen, buyers can negotiate better prices and ensure that they are receiving authentic, high-quality materials tailored to their specific needs.

In addition to direct sourcing, leveraging technology can enhance the procurement process. Utilizing virtual platforms that connect manufacturers and buyers can facilitate real-time communication and negotiation, leading to favorable terms. Online marketplaces and trade fairs also provide opportunities to observe product quality and build relationships with suppliers, ensuring a reliable supply chain. These strategies not only reduce costs but also improve overall satisfaction by securing exactly what is needed for any project.

The manufacturing process behind high-quality perforated metal screens is evolving rapidly, driven by technological advancements and innovative techniques. One prominent method is hydroforming, which utilizes high-pressure fluids to shape sheet metal into complex geometries. This nonconventional approach not only enhances the precision of the formed parts but also reduces material waste, making it a sustainable choice in modern manufacturing. According to recent industry reports, hydroforming has been shown to improve yield rates significantly, achieving up to 30% more efficiency compared to traditional deep drawing techniques.

Another transformative process in producing perforated metal screen panels is fine blanking. This method allows for the creation of intricate metal shapes with minimal burrs and a smooth surface finish, essential attributes for high-quality screens. With advancements in machine learning, manufacturers are optimizing stamping operations, leading to greater precision and consistency. Research indicates that the integration of AI in manufacturing processes can boost production speed by 20% while maintaining stringent quality standards. The combination of these state-of-the-art techniques positions manufacturers to meet the growing demands for custom perforated metal solutions in various industries, from construction to automotive applications.

Maintaining perforated metal screen panels is essential to ensure their longevity and functionality. First and foremost, regular cleaning is crucial. Dust, debris, and environmental pollutants can accumulate on the surface, leading to corrosion over time. Gentle washing with mild soap and water, followed by a thorough rinse, will keep the panels looking new. For tougher stains, a soft brush can be used to avoid scratching the surface.

Another best practice involves inspecting the panels for signs of damage or wear. Over time, exposure to the elements may result in rust or deformation. Early detection allows for timely repairs, which can prevent more extensive issues down the line. Additionally, applying a protective coating periodically can enhance resistance against corrosion, especially in harsh weather conditions. By adhering to these maintenance tips, you can ensure that your perforated metal screen panels not only maintain their aesthetic appeal but also perform effectively for years to come.

| Dimension (mm) | Hole Shape | Material Type | Thickness (mm) | Surface Treatment | Maintenance Tips |

|---|---|---|---|---|---|

| 1000 x 2000 | Round | Aluminum | 1.5 | Powder Coated | Clean with mild soap and water. |

| 1200 x 2400 | Square | Stainless Steel | 2.0 | Galvanized | Avoid abrasive cleaners. |

| 800 x 2000 | Hexagonal | Mild Steel | 1.0 | Anodized | Regular checks for rust. |