Perforated Screen Panels play a crucial role in various industries. These panels are designed with precise holes that allow for effective filtration and separation processes. Their applications range from construction to agriculture, making them versatile tools.

Industries use Perforated Screen Panels to optimize production. In mining, they help sort materials efficiently. In construction, they can enhance air circulation and control light. However, users often overlook maintenance. Without proper care, the panels can clog and lose efficiency. Regular cleaning is essential for performance.

These panels can be custom-made for specific needs. Various hole sizes and patterns are available. It's important to choose the right configuration for each application. Reflecting on these choices can lead to better outcomes. Attention to detail is key in selecting the ideal Perforated Screen Panels. Users should always consider their unique requirements to achieve maximum benefits.

Perforated screen panels are versatile items widely used in various industries. These panels feature numerous small holes that allow for the passage of air, liquid, or light. Their design makes them suitable for filtration applications, allowing different materials to pass through while blocking others. This feature is important in settings like construction, manufacturing, and even art installations.

The holes in perforated screen panels come in various shapes and sizes. This customization allows designers to choose the best option for their specific needs. For instance, larger holes may enhance airflow, while smaller ones can provide better filtration. Many users note that choosing the right hole size is crucial for achieving desired results. Yet, it can be a trial-and-error process.

In many applications, perforated screens are also used to create aesthetic patterns. Interior designers appreciate these panels for their visual appeal. However, not every design translates well into functionality. Sometimes, a beautiful pattern compromises strength or durability. Users may find themselves pondering the balance between aesthetics and practicality.

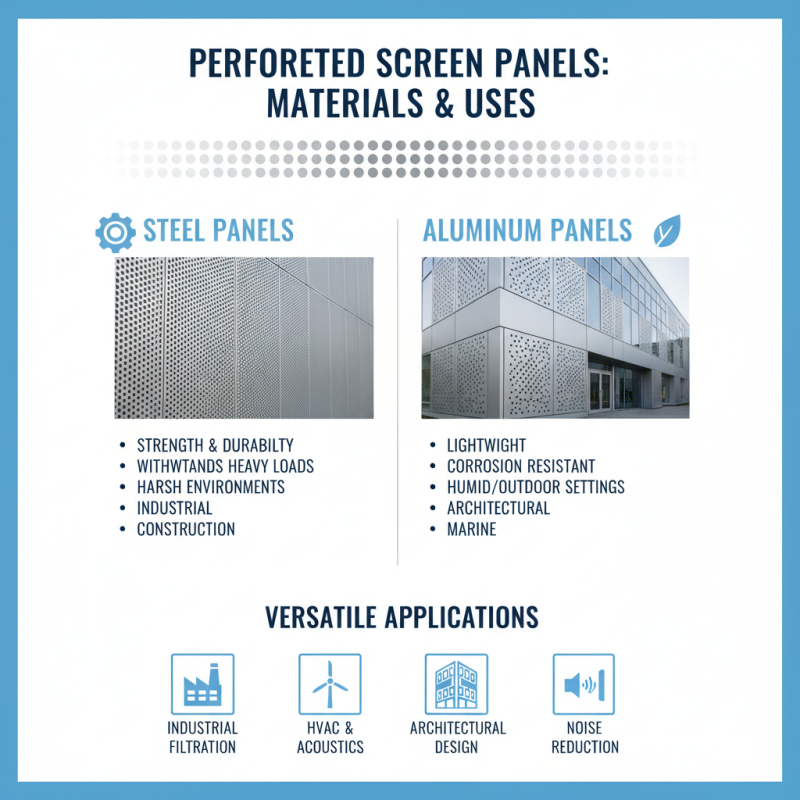

Perforated screen panels are versatile and widely used in various industries. The choice of materials for these panels is crucial for their performance and longevity. Commonly, steel is favored for its strength and durability. It can withstand heavy loads and harsh environments. Aluminum is another popular choice, known for its lightweight and corrosion resistance. This makes aluminum panels ideal for applications in humid or outdoor settings.

In addition to steel and aluminum, plastic materials like polycarbonate are also commonly utilized. They are often chosen for their impact resistance and transparency. These features allow for versatile design options while maintaining structural integrity. Wood can sometimes be used, though it’s less common due to its susceptibility to weathering and wear.

Choosing the right material often depends on the specific application. Too often, decisions are made based solely on cost, overlooking the long-term implications. It's important to consider factors like longevity and environmental conditions. Users may find themselves reflecting on choices made in haste, especially when performance issues arise. Emphasizing quality materials can lead to better outcomes in the long run.

Perforated screen panels are essential across many industries. These panels are made from various materials. They have holes that allow for air, liquid, or light passage. This feature is critical in applications ranging from construction to agriculture.

In the mining sector, perforated screen panels serve a vital role. They help sift and separate various materials. According to industry reports, up to 80% of mining operations rely on this technology for efficiency. These panels improve the quality of mined products. In the architecture world, they provide aesthetic solutions. They can enhance building facades and improve ventilation. Their patterns can be both functional and visually appealing.

Tip: Always consider the material's durability. Different environments require different grades of materials. In the food industry, perforated panels help in packaging and processing. They allow for proper airflow during production. However, maintaining hygiene standards is crucial. Regular inspections can prevent contamination.

Tip: Look for custom designs that fit your specific needs. Not all applications are the same. With careful planning, perforated screen panels can solve unique challenges. Quality and efficiency matter the most.

Perforated screen panels are versatile tools widely used in various industries. These panels feature a series of holes, allowing for both visibility and airflow. The design can be customized according to specific needs. Their lightweight nature makes them easy to install. This flexibility opens up many possibilities in different settings.

One significant benefit of using perforated screen panels is their ability to enhance space utilization. In offices, these panels can act as room dividers while maintaining an open feel. This is crucial for collaborative environments. Moreover, the added airflow helps with ventilation, creating a more comfortable workspace. They are also effective in controlling noise levels in busy areas.

Another advantage is their durability. Made from robust materials, they resist wear and tear, making them a reliable choice for long-term use. While they are effective, some users report issues with cleaning. Dust can accumulate in the holes, requiring regular maintenance. Balancing durability with aesthetic appeal can sometimes be a challenge when designing these panels. Overall, exploring these aspects can help achieve better functionality.

Perforated screen panels are versatile tools in various industries. When installing these panels, proper alignment is crucial. Misalignment can lead to inefficiencies and increased maintenance costs. According to industry reports, correct installation can boost performance by up to 15%.

Maintenance is key to extending the lifespan of perforated screen panels. Regular inspections help identify wear and tear early. Notably, about 20% of panel failures are due to accumulated debris or clogging. Effective cleaning schedules can mitigate these issues. Remember, a clean screen is a productive screen.

**Tips:**

- Always use the recommended tools to avoid damage.

- Schedule inspections quarterly to catch potential issues early.

- Don’t overlook small repairs; they can prevent larger failures.