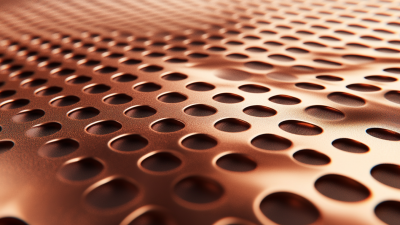

Perforated Mesh Sheet is a versatile material used across various industries. Its unique design features evenly distributed holes, allowing for airflow, light, and drainage. This adaptability makes it invaluable in construction, furniture, and filtration applications.

In construction, Perforated Mesh Sheet can enhance both aesthetics and functionality. It serves as a decorative element while providing necessary structural support. In furniture design, its lightweight nature allows for creative innovations in pieces that promote comfort and style. However, are these designs always practical?

Moreover, the use of Perforated Mesh Sheet in filtration systems demonstrates its efficiency in separating particles. Yet, one must question if this effectiveness comes at a cost to quality. Industries constantly explore new uses, but challenges remain in maintaining durability and cost-effectiveness. Reflecting on these issues can lead to innovative solutions.

Perforated mesh sheets have become essential in construction and architecture. These materials are favored for their strength and lightweight properties. Reports indicate that the market for perforated materials was valued at approximately $2 billion in 2022 and is expected to grow steadily. Designers often opt for these sheets for facades, allowing natural light while maintaining privacy.

In architectural projects, perforated mesh functions as an aesthetic and practical element. It enhances airflow in buildings, contributing to energy efficiency. For instance, buildings with well-designed perforated screens can reduce energy costs by up to 20%. This is important given the increasing focus on sustainable design.

However, the use of perforated mesh is not without its challenges. Ensuring the correct hole spacing requires careful planning. Mistakes in design can lead to inadequate ventilation or compromised aesthetics. Architects must balance function and form. While many projects succeed, others reveal shortcomings. A critical assessment of past applications shows that improvements are often needed.

Perforated mesh sheets play a vital role in automotive manufacturing. These sheets are crafted from various metals and plastics, making them versatile for multiple applications. They are often used in car interiors, helping reduce weight while maintaining strength. The holes allow for airflow, which is essential for cooling systems.

In engine components, perforated mesh aids in filtration. It allows fluids to pass through while capturing unwanted particles. However, the effectiveness is sometimes compromised if the mesh is not adequately designed or maintained. Regular checks are necessary to ensure optimal performance.

Another area of application is sound dampening. Perforated sheets can reduce noise within vehicles, enhancing comfort for passengers. But this too requires careful selection and installation. An incorrect application can lead to ineffective noise reduction, causing discomfort. This highlights the need for manufacturers to be attentive to material choices and designs.

This chart illustrates the utilization of perforated mesh sheets across various industries, highlighting the automotive manufacturing sector as the leading user, followed by construction and food processing. The data reflects the importance of perforated mesh sheets in enhancing product efficiency and functionality.

In the HVAC industry, perforated mesh sheets play a crucial role. They are widely used in ventilation systems to improve air flow. These sheets allow for effective distribution of air throughout a building. The design of the holes helps reduce noise while maintaining strong structural integrity. Access to fresh air is vital for indoor environments, and these sheets help achieve that.

Tips: When selecting perforated mesh, consider hole size and spacing. This affects the air flow rate and noise levels. Standard sizes may not suit all applications. It's essential to evaluate specific needs.

Proper installation is key. Making sure the sheets fit securely can prevent leaks. A poorly sealed mesh can lead to inefficiencies. Regular maintenance is also important to ensure long-lasting performance. Dust and debris can clog perforations, diminishing air quality over time.

Be aware that not all materials will perform the same way. Some may corrode faster, especially in humid environments. Selecting the right material can save time and costs in the long run. Investing in quality perforated mesh can drastically improve HVAC efficiency.

Perforated mesh sheets are transforming modern agriculture. Farmers use these sheets for various applications, enhancing efficiency and productivity. The perforations allow air and sunlight to penetrate while protecting crops from pests. This balance aids in maintaining healthier plants.

Irrigation systems also benefit from perforated mesh. They help distribute water evenly across fields. This application reduces waste and conserves water. However, not all setups yield the desired results. Farmers sometimes struggle with uneven water distribution. Adjustments and trials are often necessary to find the right fit.

In greenhouse construction, perforated mesh sheets are vital. They provide ventilation while maintaining a controlled environment. Overreliance on these materials can lead to issues if not monitored. For example, too much sunlight can harm delicate crops. Observing and adapting to real-time conditions is crucial for success.

| Use Case | Industry | Benefits | Material |

|---|---|---|---|

| Soil Erosion Prevention | Agriculture | Reduces soil loss and protects crops | Steel, Aluminium |

| Crop Protection | Horticulture | Prevents pests and animals from damaging crops | Plastic, Stainless Steel |

| Water Drainage | Landscaping | Facilitates better water flow and drainage | Galvanized Steel, PVC |

| Aeration | Gardening | Improves soil health and root growth | Aluminium, Fabric |

| Anti-Compaction | Agriculture | Maintains soil structure and enhances crop yield | Reinforced Plastic |

| Plant Support | Greenhouses | Stabilizes plants and supports climbing varieties | Metal Mesh |

| Temperature Regulation | Agricultural Storage | Helps to control the microclimate | Aluminium, Composite |

| Material Screening | Processing | Separates various soil and aggregate types | Metal |

| Windbreak | Orchards | Protects young trees from wind damage | Wood, Vinyl |

| Composting Aid | Waste Management | Facilitates airflow and improves decomposition | Steel, Plastic |

Perforated mesh sheets are transforming retail and display design. Their versatility is impressive. Retailers utilize these sheets to enhance product visibility. Think of a clothing store showcasing apparel through stylish displays. The holes in the mesh allow light and airflow, promoting a modern feel.

Studies show that displays using perforated mesh can increase consumer engagement by 30%. This creates a better shopping experience. Visual appeal matters. For example, displays can change rapidly without significant effort. Adaptability is key in retail design today. Sometimes, though, the holes may distract from the product. Finding the right balance is crucial.

In restaurants, perforated mesh offers a unique solution for menu displays. They can suggest freshness and creativity. However, one concern is durability; poorly constructed sheets can bend or tear. Crafting robust designs is challenging. Retailers must be mindful of these issues. Balancing aesthetics with resilience remains a topic for reflection in the industry.