In the ever-evolving landscape of industrial materials, the significance of versatile components such as the perforated copper sheet cannot be overstated. As highlighted in the latest report by the Global Copper Association, the copper market is projected to grow at a CAGR of 4.4% through 2027, driven primarily by its unique properties, including excellent conductivity, durability, and malleability.

Perforated copper sheets, specifically, offer a myriad of applications across various sectors, including architecture, HVAC, and electronics, where their aesthetic appeal and functional advantages make them indispensable. This blog will delve into five compelling reasons why incorporating perforated copper sheets in your next project is not just beneficial but essential for optimizing performance and design.

Perforated copper sheets are revolutionizing design flexibility in various industries, from architecture to product design. One significant advantage they offer is their versatility. According to a report from the Architectural Review, perforated metals have increased in demand by over 25% in the last five years, driven by their aesthetic appeal and functional properties. The ability to customize hole sizes and patterns allows designers to create unique visual effects while maintaining optimal performance for sound absorption and airflow.

Moreover, perforated copper sheets contribute to sustainability efforts. The Copper Development Association states that copper is 100% recyclable, and integrating perforated sheets into projects can enhance sustainability without sacrificing style. Whether utilized in decorative facades, privacy screens, or functional barriers, these sheets combine beauty and utility effectively. The balance of light and shadow created by varying hole patterns not only elevates the design but also optimizes energy efficiency in buildings, making perforated copper an essential material for forward-thinking projects.

| Feature | Description | Benefits |

|---|---|---|

| Design Flexibility | Can be tailored to various designs with different hole sizes and patterns. | Allows for unique aesthetics and functionalities, enhancing creative freedom. |

| Lightweight | Perforated sheets weigh less than solid sheets of the same dimensions. | Easier handling and installation, reducing labor costs. |

| Ventilation | Allows for airflow while maintaining structural integrity. | Ideal for applications requiring air circulation without compromising durability. |

| Aesthetic Appeal | Provides a visually striking look that can enhance any space. | Increases the overall value and appeal of design projects. |

| Durability | Copper is resistant to corrosion and tarnish, ensuring longevity. | Reliable for outdoor and indoor applications under various environmental conditions. |

Perforated copper sheets have increasingly become a favorite choice in architectural projects due to their numerous advantages. One of the primary benefits is their aesthetic appeal; the unique pattern of perforations allows for creative design elements while allowing natural light and ventilation. According to a report by Grand View Research, the global demand for perforated metals in construction and architectural applications is expected to grow significantly, projected to reach over $10 billion by 2025. This trend indicates a strong preference for materials that combine functionality with artistic expression, making perforated copper sheets a perfect fit.

In addition to their visual benefits, perforated copper sheets offer excellent durability and corrosion resistance. The natural antimicrobial properties of copper make it an ideal material for environments requiring high hygiene standards, such as healthcare facilities and food-related projects. A study conducted by the Copper Development Association found that surfaces made from copper and its alloys can reduce the survival of certain bacteria by 99.9% within two hours of exposure. This statistic highlights the material's contribution to creating safer architectural environments, thereby enhancing the overall quality and sustainability of building designs.

Perforated copper sheets are increasingly recognized for their capability to enhance airflow in various applications, from HVAC systems to decorative architecture. The strategic placement of holes in the sheets allows for improved ventilation, which is particularly beneficial in industrial settings where excess heat can significantly affect performance. According to a report by the International Journal of HVAC Engineering, systems utilizing perforated materials can see an increase in airflow efficiency by up to 30%, leading to better energy conservation and reduced operational costs.

Moreover, the unique properties of copper serve to amplify these benefits. Copper is known for its excellent thermal conductivity, which means that when combined with perforation, it not only allows air to flow freely but also aids in dissipating heat more effectively. A study published in the Journal of Materials Science indicates that incorporating perforated copper sheets in heat exchange systems can enhance heat transfer rates by 25% compared to traditional solid materials. This dual functionality not only optimizes the efficiency of systems but also extends their lifespan, making perforated copper sheets a critical choice for modern engineering projects focused on sustainability and performance.

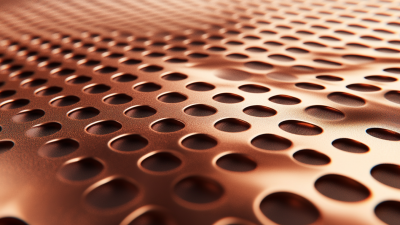

When it comes to selecting materials for your next project, perforated copper sheet stands out for its unique combination of durability and aesthetic appeal. The warm, distinct hue of copper lends an elegant touch to any design, making it a favorite among architects and interior designers. Its versatility is remarkable; whether used in decorative panels, ceiling tiles, or furniture accents, copper sheet adds a layer of sophistication that is hard to replicate with other materials.

Moreover, the durability of copper sheets enhances their practicality. Copper is resistant to corrosion and wear, ensuring that your installations maintain their beauty over time. This longevity makes it a wise investment for projects that require both style and durability.

**Tips for Using Perforated Copper Sheet:**

1. When designing, consider incorporating lighting behind perforated panels. This not only highlights the unique texture of the copper but also creates stunning visual effects throughout the space.

2. Ensure proper surface treatment to maintain the copper's luster and protect it from tarnishing. Regular care will keep your installation looking new and vibrant.

3. Pair copper with complementary materials, like wood or stone, to achieve a balanced and harmonious design that elevates the overall aesthetic of your project.

Perforated copper sheets have become increasingly popular in modern construction, thanks to their unique blend of aesthetic appeal and functional versatility. One of the most prominent applications is in architectural facades, where these sheets can enhance a building's exterior while providing ventilation and natural light. The intricate patterns achievable with perforation not only contribute to visual interest but also enable a structure to blend seamlessly with its surroundings, promoting sustainability in design.

In addition to facades, perforated copper sheets are ideal for environment-friendly solutions in interior spaces, such as acoustic panels and decorative partitions. The inherent properties of copper contribute to sound absorption and thermal regulation, making them perfect for creating comfortable indoor environments. Furthermore, due to their antimicrobial properties, they are increasingly used in hospitals and mass transit systems, ensuring cleanliness and safety while maintaining modern aesthetics. The versatility of perforated copper sheets positions them as an essential material in contemporary construction projects, paving the way for innovation and creativity.