The 2025 China Import and Export Fair, also known as the 138th Canton Fair, is poised to showcase a diverse array of products, with a significant focus on innovative building materials, particularly Perforated Steel Panels. As the construction and architectural sectors continue to evolve, the demand for perforated panels is projected to increase, driven by their aesthetic versatility and functional benefits such as enhanced ventilation and sound attenuation. According to a recent market analysis by Grand View Research, the global perforated metal market is expected to reach USD 12.17 billion by 2027, growing at a compound annual growth rate (CAGR) of 5.3% from 2020 to 2027. This trend reflects a broader shift towards sustainable construction practices and the integration of creative design solutions in urban environments. As stakeholders gather at the Canton Fair, exploring the latest advancements in Perforated Steel Panels will be crucial for tapping into emerging market opportunities.

The market for perforated steel panels in China has experienced significant growth in recent years, driven by increasing demand in various industries such as construction, automotive, and manufacturing. These panels are highly valued for their versatility, durability, and aesthetic appeal, making them suitable for applications ranging from façade designs to noise control solutions. As environmental concerns rise, the demand for sustainable materials has further fueled interest in perforated steel, which can be easily recycled and integrated into green building practices.

Today, key players in the Chinese market are focusing on innovation and technology to enhance the production of perforated steel panels. Advances in manufacturing processes have allowed for greater customization, enabling clients to select unique patterns and hole sizes that meet specific project requirements. Additionally, the expansion of e-commerce platforms has made it easier for manufacturers and suppliers to connect with customers, enhancing market accessibility. As the 2025 China Import and Export Fair approaches, stakeholders will be keen to explore these trends and discover new opportunities in this dynamic sector.

The manufacturing of perforated steel panels is witnessing significant advancements, particularly in preparation for the 2025 China Import and Export Fair. Key innovations are focused on enhancing functionality and efficiency, with modern techniques such as laser cutting and automated punching machines coming to the forefront. These technologies allow for greater precision in the creation of intricate patterns and designs, which not only meet aesthetic demands but also improve the structural integrity and overall performance of the panels.

Moreover, sustainability has become a pivotal aspect of innovation in this sector. Manufacturers are now prioritizing eco-friendly practices by utilizing recycled materials and developing finish treatments that reduce environmental impact. Coupled with smart manufacturing processes that leverage artificial intelligence, these advancements aim to optimize production efficiency while minimizing resource consumption. As the industry evolves, the focus on integrating cutting-edge technology with sustainable practices will likely position perforated steel panels as a preferred choice for consumers in various applications, from architecture to automotive designs.

| Trend/Innovation | Description | Expected Impact | Market Demand (2025) |

|---|---|---|---|

| Advanced Manufacturing Techniques | Utilization of automated CNC machines for precise perforation. | Improved accuracy and reduced production time. | High demand projected due to increased customization. |

| Sustainability Initiatives | Focus on eco-friendly materials and production processes. | Enhanced company reputation and consumer trust. | Growing interest in sustainable products across industries. |

| Innovative Design Applications | Creative uses of perforated panels in architecture and interior design. | Increased aesthetic appeal and functional versatility. | Spike in demand for decorative panels in construction. |

| Digital Customization Platforms | Online tools for clients to design custom perforated panels. | Enhanced customer engagement and satisfaction. | Rising trend in personalized design solutions. |

| Improved Coating Techniques | Application of advanced coatings for better durability and aesthetics. | Increased longevity and reduced maintenance costs. | Higher demand in areas prone to corrosion. |

The perforated steel panel market is witnessing significant growth, fueled by the increasing demand for innovative architectural solutions and sustainable building materials. Key players in this industry are focusing on product differentiation and technological advancements to maintain a competitive edge. Companies are investing in research and development to enhance the performance and aesthetic appeal of perforated steel panels, offering various patterns and customizations to meet the specific requirements of diverse projects, ranging from commercial buildings to residential applications.

In this evolving landscape, major competitors are adopting strategic collaborations and partnerships to expand their market reach and improve production capabilities. The competitive dynamics are characterized by the presence of both established manufacturers and emerging startups, each bringing unique strengths to the table. As market players strive to capture a larger share, they are also prioritizing sustainability by incorporating eco-friendly practices in their production processes, which aligns with the global trend towards greener construction solutions. This increasingly competitive environment will likely shape the future trajectory of the perforated steel panel market leading up to the 2025 China Import and Export Fair.

As the 2025 China Import and Export Fair approaches, it is crucial to examine the evolving consumer trends and preferences that are shaping the perforated steel sector. Modern consumers are increasingly prioritizing sustainability and eco-friendliness in their purchasing decisions. This shift drives manufacturers to innovate by utilizing environmentally sustainable methods in the production of perforated steel panels. The market is seeing a rise in demand for products that not only meet aesthetic needs but also contribute to energy efficiency and environmental responsibility.

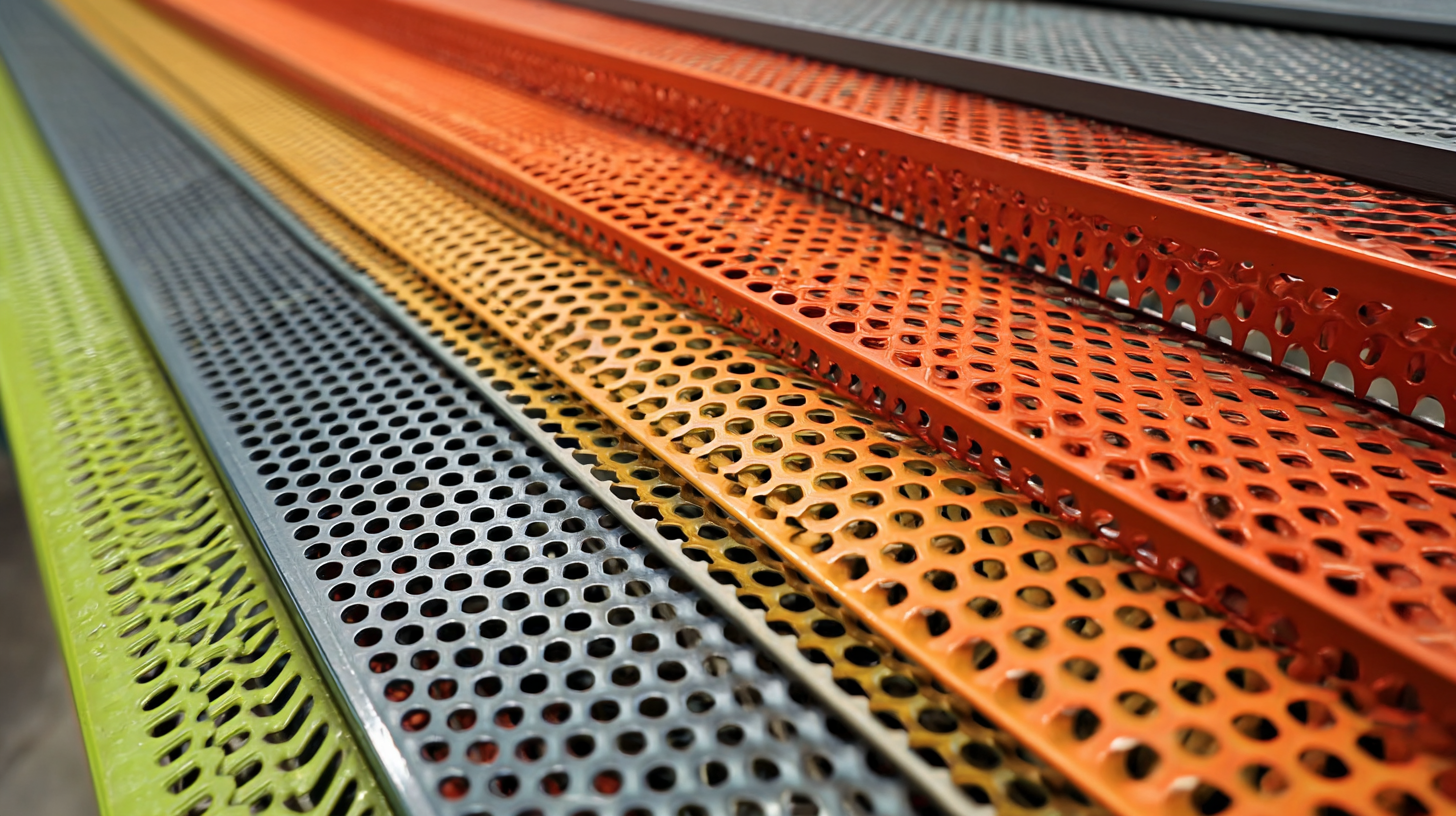

In addition to sustainability, consumers are showing a growing preference for customizability and versatility in perforated steel panels. Businesses are adapting to this trend by offering a variety of styles, sizes, and finishes, enabling clients to tailor products to their specific requirements. This trend reflects a broader movement toward personalization in construction materials, where the functionality and design of perforated panels play a pivotal role in architectural projects. As these consumer preferences continue to evolve, companies are tasked with staying ahead of the curve, ensuring that they meet the diverse needs of their clientele while fostering innovation in the perforated steel market.

As sustainability becomes a pivotal focus in manufacturing, the production of perforated steel panels is undergoing significant transformation. With the global market projected to reach $5.3 billion by 2035, spurred by demand in architecture, automotive, and industrial applications, the emphasis on environmentally friendly practices is more critical than ever. The adoption of sustainable materials and technologies not only positions manufacturers favorably in the marketplace but also responds to the increasing consumer demand for eco-conscious products.

Recent experimental analyses have highlighted the benefits of integrating sustainable cores in structural applications, particularly in sandwich panels. These materials, designed to withstand impact loads while minimizing environmental footprints, represent a shift towards greener production methods. Furthermore, the life cycle assessment comparisons between alkaline and proton exchange membrane electrolyser systems reveal a growing trend in optimizing energy efficiency and reducing carbon emissions within the industry. Such advancements indicate a pathway towards achieving sustainability goals, ultimately benefiting the perforated steel panel market as it adapts to the changing landscape of manufacturing practices.

This chart illustrates the market trends for perforated steel panels from 2021 to 2025, highlighting the rising global demand alongside the increasing percentage of sustainable production practices in manufacturing. The data indicates a significant shift towards sustainability over the years, culminating in a projected demand surge by 2025.