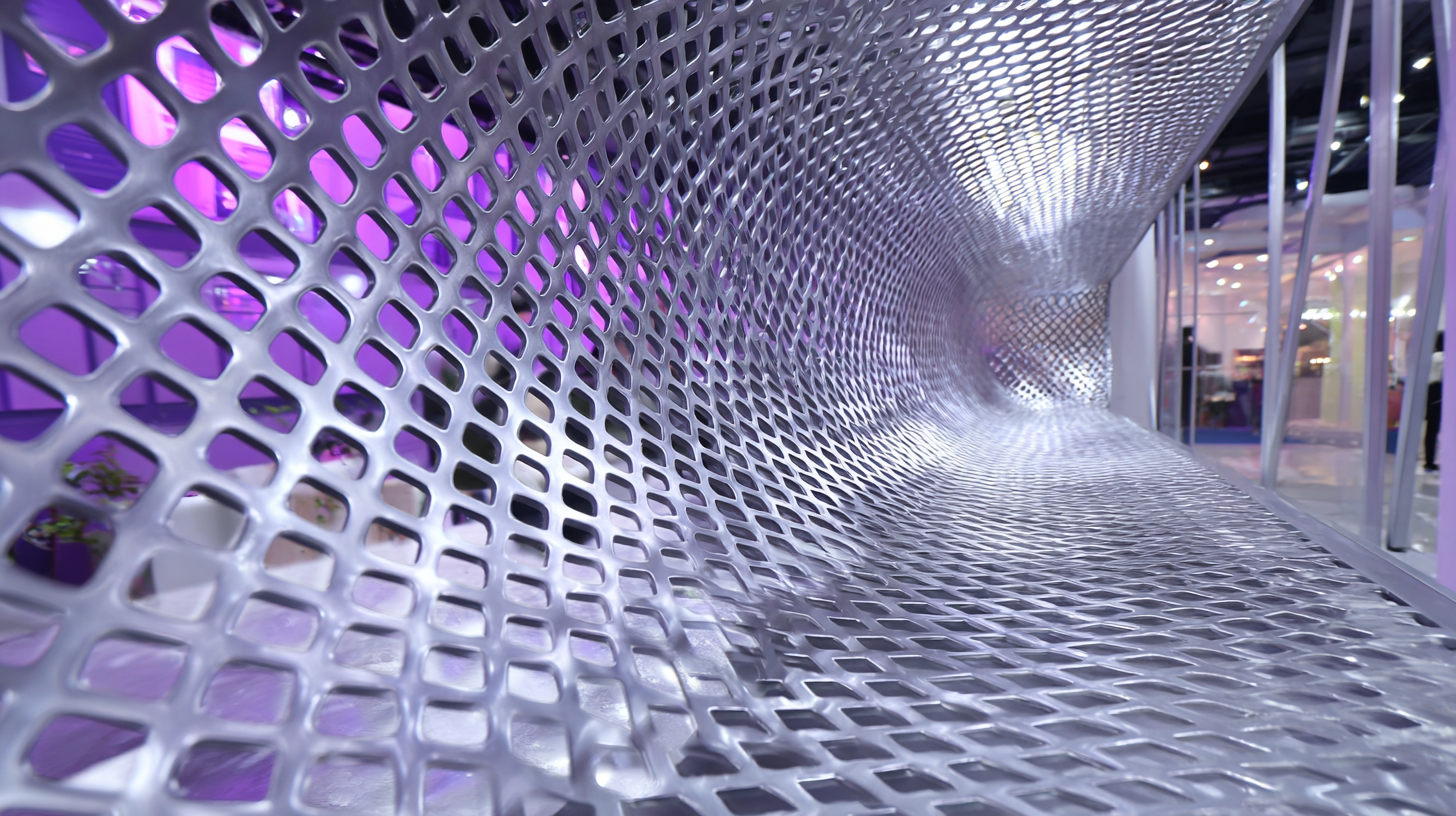

The 2025 China Import and Export Fair, also known as the 138th Canton Fair, serves as a vibrant platform for international trade and innovative solutions across various industries. Among the many exhibits, Perforated Metal Screen Panels stand out as a pioneering solution that combines functionality and aesthetic appeal. These panels, with their unique design and versatile applications, offer architects and designers the opportunity to enhance architectural projects while promoting ventilation and light penetration. As the fair showcases the latest trends and technologies, the incorporation of Perforated Metal Screen Panels not only highlights a shift towards sustainable building materials but also provides insights into their potential for transforming spaces in commercial and residential settings. Attendees can explore how these panels contribute to modern design concepts, making them a focal point of innovation at this year's event.

Perforated metal screen panels are emerging as a transformative element in architectural design, leading to innovative applications that enhance both functionality and aesthetic appeal. For instance, in contemporary projects like the student hub at Niagara College, architects have effectively utilized perforated screens to facilitate passive wayfinding and create a seamless connection between interior and exterior spaces. These panels not only add an engaging visual element but also serve practical purposes, such as light filtration and privacy.

Tips for Incorporating Perforated Metal Screens:

1. Blend with Nature: Consider using perforated panels that mimic natural patterns or textures, allowing structures to harmonize with their surroundings while providing shade and ventilation.

2. Color and Finish Variety: Explore available finishes and colors to complement your building's façade. Whether opting for a sleek metallic sheen or painted options, these screens can elevate your project's overall look.

Architects are increasingly leaning towards metal cladding and innovative screen solutions to adapt to modern demands. The integration of these materials not only enhances the durability of façades but also introduces a dynamic element to the building design—allowing for flexibility and creativity that traditional materials might not offer.

Perforated metal screen panels are becoming increasingly popular in modern construction due to their sustainability benefits. These panels, made from recycled metal and designed with strategically placed holes, not only enhance aesthetic appeal but also contribute to energy efficiency. By allowing natural light and ventilation, perforated metal surfaces reduce reliance on artificial lighting and HVAC systems, thus lowering energy consumption and greenhouse gas emissions.

Moreover, the durability of perforated metal makes it a sustainable choice for building materials. Unlike traditional materials that may need replacing after a few years, perforated metal can withstand harsh weather conditions and is resistant to corrosion. This longevity not only decreases the frequency of replacements but also minimizes waste associated with construction projects. Additionally, many manufacturers prioritize eco-friendly production methods, ensuring that the entire lifecycle of the product—from creation to installation—adheres to sustainability principles. This innovative approach represents a significant leap toward greener building practices in the construction industry.

The Asia-Pacific region is poised for significant growth in the perforated metal market, projected to reach USD 1.5 billion by 2025, according to a recent industry report by Research and Markets. This surge is driven by the growing demand across various sectors, including construction, automotive, and architectural designs. Perforated metal screen panels offer not only aesthetic appeal but also functional benefits such as lightweight construction and enhanced ventilation, making them increasingly popular among architects and engineers.

Innovations in manufacturing processes and design have contributed to the rising adoption of perforated metal solutions. With advancements in technology, manufacturers are now able to create customized panels that meet specific design and performance requirements, which aligns well with current market trends emphasizing sustainability and energy efficiency. The Asia-Pacific market is expected to account for over 35% of global perforated metal consumption, as industries across countries like China and India invest in infrastructure development. This growth points to a robust future for perforated metal applications, highlighting their versatility and capacity to meet modern architectural and industrial needs.

Perforated metal screen panels are gaining traction in urban development projects, thanks to their multifunctional benefits. A recent case study highlights the transformation of a historical building into a creative laboratory, demonstrating how perforated screens can effectively facilitate passive ventilation while maintaining aesthetic integrity. Such designs not only improve air circulation but also provide shading, allowing for more energy-efficient indoor environments. In fact, the U.S. Green Building Council reports that implementing these materials can reduce energy consumption by up to 30%, contributing significantly to sustainability goals.

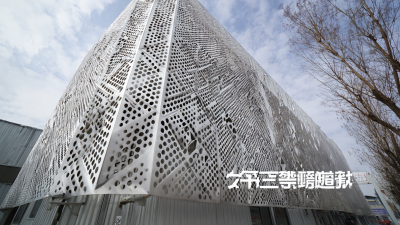

In another instance, a new materials experience center in Shanghai utilizes perforated panels to create a high-tech yet minimalist façade. This project showcases how innovative design can leverage the artistic potential of perforated metal, enhancing the visual appeal of urban structures. The panels can be customized to fit various architectural styles, leading to unique urban landscapes.

Tips: When considering perforated metal screens for your project, explore different hole patterns and sizes to achieve both functionality and desired aesthetics. Additionally, consult local regulations regarding shade and ventilation to ensure compliance while enhancing sustainability. Always prioritize materials that contribute to LEED certification for building projects.

The 2025 China Import and Export Fair is set to showcase groundbreaking advancements in the manufacturing of perforated metal panels, a trend that reflects the industry’s commitment to innovation and sustainability. With technological developments enhancing both efficiency and precision, manufacturers now utilize advanced CNC machining and laser cutting techniques that allow for intricate designs and perfectly executed patterns. This not only elevates aesthetic appeal but also contributes to the functional aspects of perforated metal screens, such as improved airflow and light filtration.

Moreover, the introduction of state-of-the-art materials, including lightweight alloys and corrosion-resistant coatings, has revolutionized the performance standards of perforated metal panels. These enhancements ensure durability and longevity, positioning them as a preferred choice in various applications, from architectural facades to industrial processes. As companies demonstrate their cutting-edge products at the fair, the emphasis on innovative design paired with sustainable practices underscores a significant shift in the metal manufacturing landscape, paving the way for future advancements in the field.

| Application Area | Material Type | Panel Thickness (mm) | Hole Size (mm) | Production Technology | Sustainability Feature |

|---|---|---|---|---|---|

| Architectural Design | Aluminum | 2.5 | 10 | Laser Cutting | Recyclable Material |

| Industrial Applications | Stainless Steel | 3.0 | 8 | Punching | Energy Efficient Production |

| Sound Insulation | Carbon Steel | 1.5 | 5 | CNC Machining | Recyclable and Durable |

| Landscape Architecture | Copper | 2.0 | 15 | Water Jet Cutting | Biodegradable Coating |