The global market for perforated aluminum sheets is witnessing a significant transformation, driven by innovative applications and emerging trends across various sectors. According to a recent report by MarketsandMarkets, the market for metal perforation is projected to reach USD 1.8 billion by 2025, with a notable growth rate attributed to the increasing demand in construction, automotive, and aerospace industries. Innovations in perforation technology are enhancing the aesthetic and functional potential of perforated aluminum sheets, making them versatile solutions for architects and engineers. This evolution not only meets the growing consumer preferences for sustainability and lightweight materials but also aligns with the global push towards energy efficiency. As we analyze the trends and innovations shaping this market, it becomes evident that perforated aluminum sheets are set to play a pivotal role in the design and construction landscape of the future.

The demand for perforated aluminum sheets is experiencing significant growth globally, driven by their versatile applications across various industries, including construction, automotive, and aerospace. According to a recent report from Market Research Future, the perforated aluminum sheet market is projected to grow at a CAGR of approximately 6.5% from 2020 to 2025. This growth is largely fueled by the increasing focus on lightweight materials that provide durability and strength, particularly in the automotive sector where fuel efficiency is a primary concern.

Supply dynamics are also evolving as manufacturers increasingly adopt innovative technologies to enhance production processes. Industries are embracing automated systems, allowing for greater precision in perforation and ensuring higher quality standards. Additionally, the rise of sustainable practices is leading to a preference for recycled aluminum, which contributes to the circular economy while meeting regulatory compliance. For manufacturers, keeping an eye on these trends is crucial for staying competitive.

Tip 1: Businesses should invest in smart manufacturing technologies to optimize their perforation processes and reduce waste, which can lead to significant cost savings.

Tip 2: Engaging in strategic partnerships with suppliers who prioritize sustainability can enhance your market positioning and appeal to environmentally conscious consumers.

Tip 3: Regularly analyze market reports and trends to stay ahead in the industry, as consumer preferences can shift rapidly, impacting demand dynamics significantly.

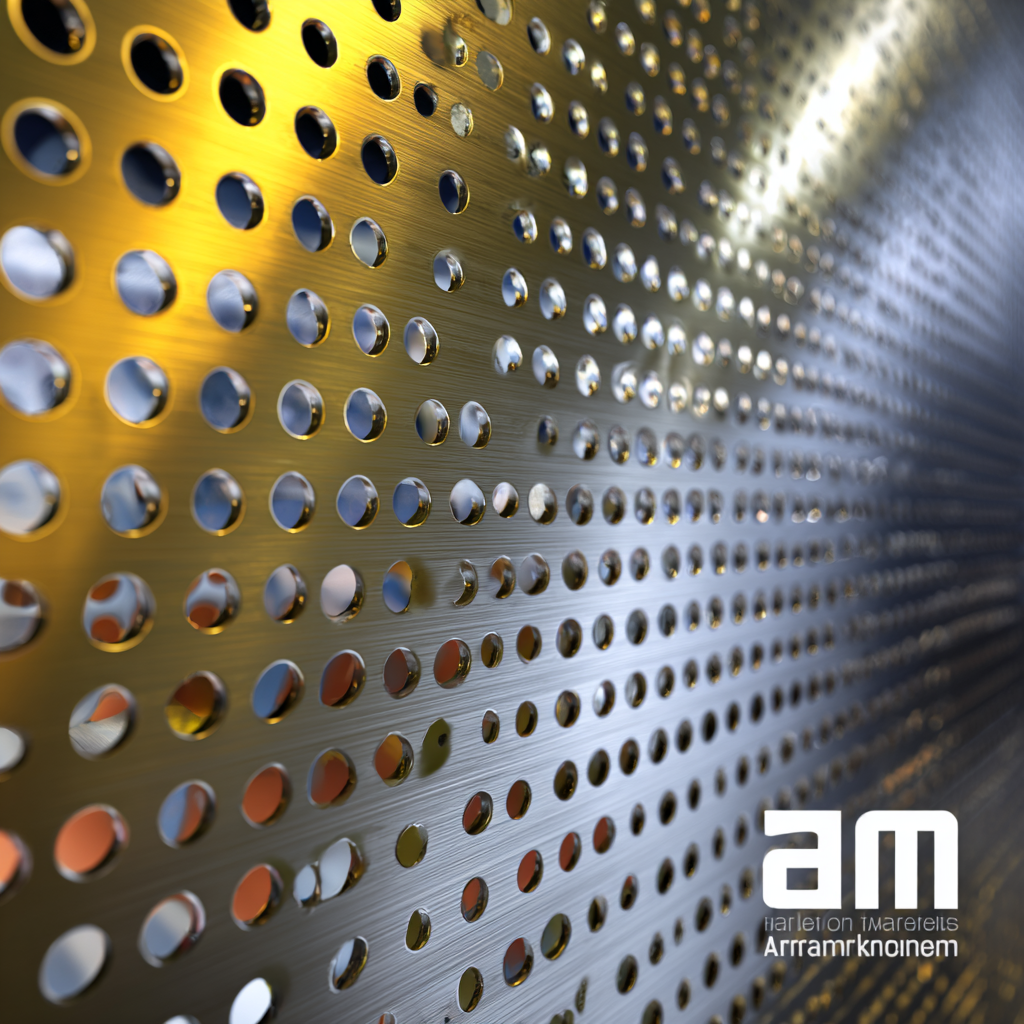

The landscape of aluminum sheet manufacturing is witnessing significant innovations that are enhancing both performance and durability, particularly in the realm of perforated aluminum sheets. One of the key advancements is the development of advanced coating technologies that not only improve corrosion resistance but also provide aesthetic customization options. These innovative coatings ensure that the aluminum sheets maintain their quality and appearance even in the most demanding environments, making them ideal for a wide range of applications, from architectural facades to industrial uses.

The landscape of aluminum sheet manufacturing is witnessing significant innovations that are enhancing both performance and durability, particularly in the realm of perforated aluminum sheets. One of the key advancements is the development of advanced coating technologies that not only improve corrosion resistance but also provide aesthetic customization options. These innovative coatings ensure that the aluminum sheets maintain their quality and appearance even in the most demanding environments, making them ideal for a wide range of applications, from architectural facades to industrial uses.

Another transformative trend is the introduction of new alloy compositions that enhance the mechanical properties of aluminum sheets. By leveraging cutting-edge metallurgical techniques, manufacturers are producing alloys that offer superior strength while maintaining lightweight characteristics. This allows for greater versatility in design without compromising structural integrity. Additionally, these innovations are driving sustainability efforts in the industry, as manufacturers seek to optimize materials to reduce waste and energy consumption during production. As these trends continue to evolve, the future of aluminum sheet manufacturing looks promising, with enhanced products that meet the increasing demands of various sectors.

The market for perforated aluminum sheets continues to expand, driven by their versatile applications across various industries. Key sectors such as construction, automotive, and aerospace leverage the unique properties of perforated aluminum sheets, which include lightweight yet robust durability, corrosion resistance, and aesthetic appeal.

In construction, these sheets are increasingly used for facades, ceiling tiles, and architectural panels, blending functionality with modern design trends.

In addition to construction, the automotive industry utilizes perforated aluminum sheets for components that require weight reduction without sacrificing strength.

This trend aligns with the industry's push towards more fuel-efficient and environmentally friendly vehicles.

Meanwhile, in aerospace, the ability to customize hole patterns based on specific design requirements has made perforated aluminum sheets integral to the manufacturing of various aircraft parts. As innovations continue to emerge in this segment, businesses are focusing on enhancing product quality and exploring new applications to stay competitive in the global market.

The aluminum industry is undergoing a significant transformation as sustainability trends and recycling practices become increasingly vital. By 2025, the push towards secondary aluminum will redefine the sector, aligning with global demands for eco-friendly materials. Experts highlight that a notable shift towards digitalization, combined with enhanced recycling technologies, will play a critical role in optimizing aluminum production processes. With a projected global consumption of over 100 million tonnes by 2025, the emphasis on sustainability and resource efficiency is paramount.

Innovations in bauxite mining and aluminum scrap recycling are key to achieving these sustainability goals. Modern practices focus on minimizing environmental impact while enhancing recovery rates. Reports indicate a surge in the aluminum can market, driven by the growing consumer preference for recyclable packaging. Countries like Romania have made significant strides, achieving recycling rates of nearly 74 percent for aluminum cans. As green aluminum gains traction, it supports the broader endeavor of decarbonizing various industries by reducing the carbon footprint associated with traditional aluminum production.

The competitive landscape of the perforated aluminum sheet market is evolving rapidly, driven by innovation and strategic growth initiatives from leading manufacturers. According to a recent market report by Grand View Research, the global perforated aluminum sheet market was valued at approximately $2.5 billion in 2020 and is expected to expand at a compound annual growth rate (CAGR) of over 5% by 2025. Key players such as Ryerson Holding Corporation and Elirial SA are adopting advanced manufacturing technologies and strategic partnerships to enhance their market position.

In addition, companies are increasingly focusing on product diversification and customization to meet the specific needs of various industries, including construction, automotive, and aerospace. For instance, manufacturers are investing in digital technologies for precision engineering and sustainability practices to minimize waste. A report by Market Research Future highlighted that more than 60% of new product developments in the perforated aluminum sector involve environmentally-friendly materials and processes, reflecting a shift towards sustainable practices that resonate with consumer preferences.

This competitive strategy not only fosters innovation but also strengthens brand loyalty among consumers, positioning these manufacturers favorably in a rapidly changing market environment.