In the competitive landscape of industrial materials, choosing the right perforated stainless steel mesh can significantly impact both performance and longevity. According to a report from the Markets and Markets Research Firm, the global perforated metal market is projected to reach USD 4 billion by 2025, reflecting a robust growth driven by expanding applications across various industries including construction, automotive, and filtration. This underscores the importance of informed decision-making in selecting perforated stainless steel mesh that meets specific project requirements.

As industry expert Dr. John Smith, a respected figure in metal manufacturing, states, “The effectiveness of perforated stainless steel mesh in applications largely depends on understanding its specifications and the environment in which it will operate.” By recognizing the critical elements such as hole size, gauge thickness, and material grade, users can optimize their choices to achieve the desired balance of strength and functionality. This guide will provide you with ten essential tips based on data-driven insights and industry best practices to navigate the complexities of selecting perforated stainless steel mesh.

When selecting perforated stainless steel mesh, it's crucial to understand the various types available in the market. Perforated stainless steel mesh comes in a range of patterns and hole sizes, which can greatly affect its functionality and aesthetic appeal. The most common types include round holes, square holes, and custom shapes, with each type serving different applications. For example, round holes are ideal for applications requiring high airflow, while square holes can provide a balanced approach to drainage and light transmission.

One essential tip for choosing the right type of perforated stainless steel mesh is to consider the application. Depending on whether you need it for architectural purposes, filtration, or safety barriers, different specifications will be more suitable. Additionally, think about the environment where the mesh will be used. For outdoor applications, opting for a mesh with corrosion resistance will ensure longevity and maintain appearance.

Another important factor is the thickness of the material. Thicker mesh can withstand more stress and is typically more durable, making it a good choice for heavy-duty uses. Assessing these elements will help you make an informed decision that meets your specific needs while ensuring you choose the best perforated stainless steel mesh for your project.

When selecting perforated stainless steel mesh, evaluating hole sizes and patterns is crucial due to their impact on functionality and performance. The size of the holes determines the material's ability to filter or allow the passage of air, light, or liquids. For example, larger hole sizes may be suitable for applications requiring high air flow, while smaller holes are ideal for more refined filtration needs. It is essential to align the hole size with the specific purpose of the mesh, ensuring optimal performance for the application in mind.

In addition to hole size, the pattern of perforations plays a significant role in determining the mesh's structural integrity and aesthetic appeal. Different patterns can distribute stress differently and affect the strength of the mesh. Common patterns include staggered and straight arrangements, each providing unique advantages based on load requirements and design preferences. Evaluating these patterns not only helps in enhancing the mechanical properties but can also be a deciding factor in the overall visual outcome of the project. Therefore, carefully considering both hole sizes and patterns is key to making an informed choice when selecting perforated stainless steel mesh.

When choosing perforated stainless steel mesh, durability and corrosion resistance are two critical factors that significantly influence selection. Stainless steel grades vary in their chemical composition, which directly affects their performance in various environments. For instance, 304 stainless steel is commonly used due to its excellent corrosion resistance against moderate atmospheric conditions and many corrosive media. It’s an ideal choice for general applications but may not excel in highly acidic or chloride-rich environments.

In contrast, for more demanding situations, 316 stainless steel may be preferred. It contains molybdenum, which enhances its resistance to pitting and crevice corrosion, making it suitable for marine applications or areas exposed to chlorides. Additionally, further options like duplex stainless steel provide a combination of high strength and superior corrosion resistance, making them an excellent choice for specialized industrial applications. Evaluating the specific environment in which the perforated mesh will be used is crucial for selecting the right stainless steel grade, ensuring longevity and reliability in performance.

| Stainless Steel Grade | Corrosion Resistance | Durability | Common Applications |

|---|---|---|---|

| 304 | Good | Moderate | Food processing, kitchen equipment |

| 316 | Excellent | High | Marine environments, chemical processing |

| 430 | Fair | Moderate | Automotive trim, kitchen utensils |

| 2205 | Very Good | High | Oil and gas industry, pulp and paper |

| 2507 | Exceptional | Very High | Desalination plants, pharmaceutical applications |

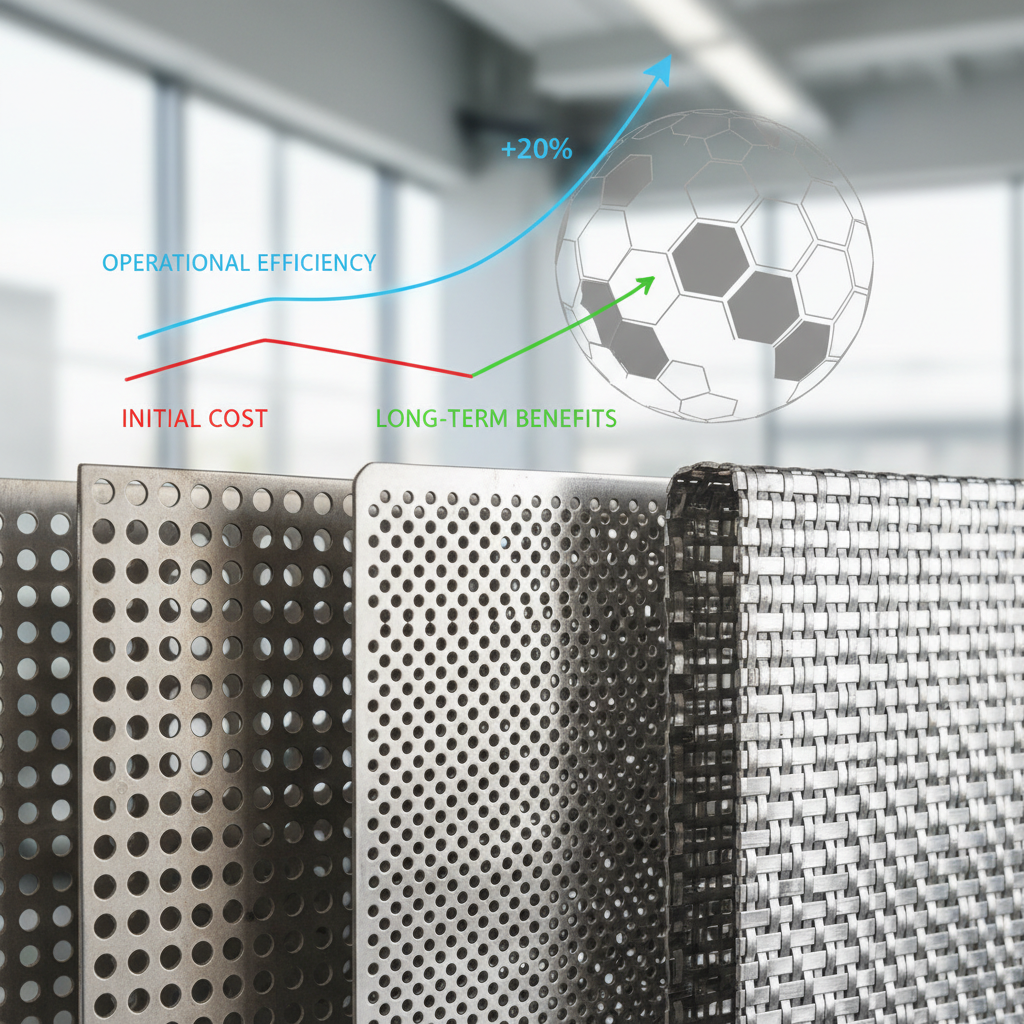

When selecting perforated stainless steel mesh, understanding the cost versus performance dynamics is crucial for optimizing your investment. A recent industry report from the International Stainless Steel Forum indicates that high-quality perforated mesh can improve operational efficiency by up to 20%, which can significantly offset initial costs. This data-driven insight highlights the importance of considering not only the upfront price but also the long-term benefits associated with stronger and more corrosion-resistant materials.

When evaluating options, prioritize your requirements based on specific applications. For example, if airflow and drainage are essential, look for meshes with larger perforation ratios. A 2023 study by Global Market Insights suggests that using heavier gauge stainless steel can improve durability by 15% in demanding environments, providing better value for your money.

In addition to performance, always consider supplier reliability. Establishing partnerships with reputable manufacturers can lead to cost savings over time through reduced maintenance and replacement needs. As you navigate your selection, keep these tips in mind to strike a balance between cost and performance, ensuring you make a wise investment in your perforated stainless steel mesh.

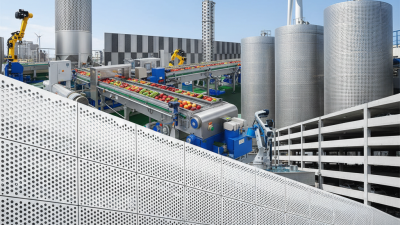

When selecting perforated stainless steel mesh, it's crucial to identify the specific applications that best suit your needs. These versatile materials are commonly used in various industries, including construction, filtration, and architectural design. For instance, in construction, perforated mesh serves as a valuable component in facades or internal partitions, allowing for both functional ventilation and aesthetic appeal. Understanding your project requirements can help you determine the right pattern size and hole configuration that will ensure optimal performance and durability.

In filtration applications, the choice of perforated stainless steel mesh is particularly important. Depending on the type of materials being filtered, such as liquids or solids, different hole sizes and shapes can be specified to achieve desired flow rates and retention characteristics. Additionally, perforated stainless steel is favored for its corrosion resistance, making it ideal for applications in harsh environments, including wastewater treatment and chemical processing. Analyzing the unique demands of your project enables you to select the right mesh configuration, ensuring efficiency and longevity in performance.