In the realm of industrial applications and architectural design, the importance of using the right materials cannot be overstated. Perforated Stainless Steel Mesh is a highly versatile component, admired for its unique combination of strength, aesthetic appeal, and practical functionality. Industry expert Dr. Emily Carter, a leading consultant in material sciences, emphasizes, "The integration of Perforated Stainless Steel Mesh not only enhances structural integrity but also introduces a design element that can elevate the overall aesthetic of any project."

This innovative material plays a critical role in various sectors, including construction, filtration, and audio engineering. By allowing for airflow and light transmission while maintaining durability, Perforated Stainless Steel Mesh meets diverse project requirements. Moreover, its customizable perforation patterns offer designers unprecedented flexibility, enabling them to balance form and function seamlessly. As projects demand more environmentally friendly and sustainable solutions, Perforated Stainless Steel Mesh emerges as an essential choice that aligns with modern design principles and practical applications.

Understanding the myriad benefits and applications of Perforated Stainless Steel Mesh is crucial for professionals aiming to achieve both visual and structural excellence in their work. As the industry continues to evolve, the role of this material will become even more pivotal, proving that its benefits extend far beyond mere aesthetics, significantly impacting project outcomes across various fields.

Perforated stainless steel mesh is a versatile material commonly used in various industries, known for its durability and functionality. This type of mesh is created by puncturing a sheet of stainless steel with precise holes, resulting in a grid-like pattern that can vary in hole size and spacing. The composition of perforated stainless steel is primarily made from high-grade stainless steel alloys, which provide resistance to corrosion, rust, and wear over time. This composition makes it particularly suitable for outdoor and industrial applications where exposure to harsh environments is a concern.

The defining characteristic of perforated stainless steel mesh lies in its ability to balance strength with lightweight properties. The holes can be customized to meet specific project requirements, allowing for optimal airflow, drainage, or light filtration, depending on the intended use. This adaptability extends from architectural designs to filtration systems, giving engineers and designers a reliable option for innovation. The combination of aesthetic appeal and practical functionality ensures that perforated stainless steel mesh remains an essential component in countless projects across various fields.

Perforated stainless steel mesh is a versatile material widely used across various industries due to its unique properties. One of the key benefits is its superior durability, which is crucial for projects that demand resilience against harsh environmental factors. According to a report by the International Stainless Steel Forum, stainless steel has a lifespan exceeding 100 years in most applications, significantly reducing the need for replacements and maintenance over time. This longevity makes it an excellent investment for construction, architectural, and manufacturing projects.

Another notable advantage of perforated stainless steel mesh is its ability to allow for light and airflow while maintaining structural integrity. This is particularly beneficial in ventilation systems and architectural designs that require aesthetics without sacrificing functionality. A study published in the Journal of Architectural Engineering highlights that using perforated materials can increase energy efficiency in buildings by up to 30%, thanks to improved ventilation and natural lighting.

Tip: When selecting perforated stainless steel mesh for your project, consider the hole size and pattern, as these factors can greatly influence both performance and appearance. Additionally, always choose grade 304 or 316 stainless steel, particularly for outdoor applications, to ensure maximum corrosion resistance and longevity.

Perforated stainless steel mesh is widely utilized across various industries due to its unique properties, such as strength, durability, and versatility.

In architectural applications, it serves as a modern design element for facades, allowing natural light while providing privacy and protection from external elements.

The intricate designs possible with perforated sheets can enhance aesthetic appeal, making them a popular choice for building exteriors and decorative panels.

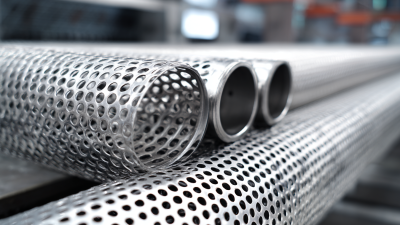

In the manufacturing sector, perforated stainless steel mesh is essential for filtration and separation processes.

It is commonly employed in the food and beverage industry for processing and packaging, where hygiene and cleanliness are critical.

The mesh not only facilitates airflow and drainage but also helps in maintaining product integrity by preventing contamination.

Additionally, in the automotive industry, this material is used for noise reduction and ventilation in vehicle components, demonstrating its multifaceted applications across different fields.

When selecting perforated stainless steel mesh for your projects, several key factors must be considered to ensure optimal performance and durability. First and foremost, the gauge of the mesh plays a critical role in its strength and application suitability. According to industry reports, thicker gauges are often recommended for heavier-duty applications, while lighter gauges can be suitable for decorative uses or where weight is a concern. Understanding the specific load requirements of your application, as well as environmental factors such as exposure to moisture or chemicals, can guide you in selecting the appropriate gauge.

Proper maintenance and care of perforated stainless steel mesh products are crucial for ensuring their longevity and functionality in various applications. Regular cleaning is essential to prevent the buildup of dirt, grease, and contaminants that can compromise the material's appearance and performance. A mild detergent mixed with warm water can be used to clean the mesh, followed by a thorough rinse to remove any residue. For more stubborn stains, non-abrasive cleaners are recommended, as abrasive materials can scratch the surface and degrade the mesh over time.

In addition to regular cleaning, it's important to conduct inspections for any signs of wear or damage. This includes checking for rust spots, which, although rare in stainless steel, can occur under certain conditions. If rust is detected, it should be addressed promptly to prevent further deterioration. Additionally, when using perforated stainless steel in environments exposed to harsh chemicals or extreme weather, applying a protective coating can enhance durability. By following these maintenance tips, you can maximize the lifespan and performance of your perforated stainless steel mesh, ensuring it remains a reliable component in your projects.