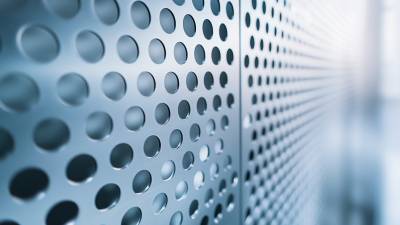

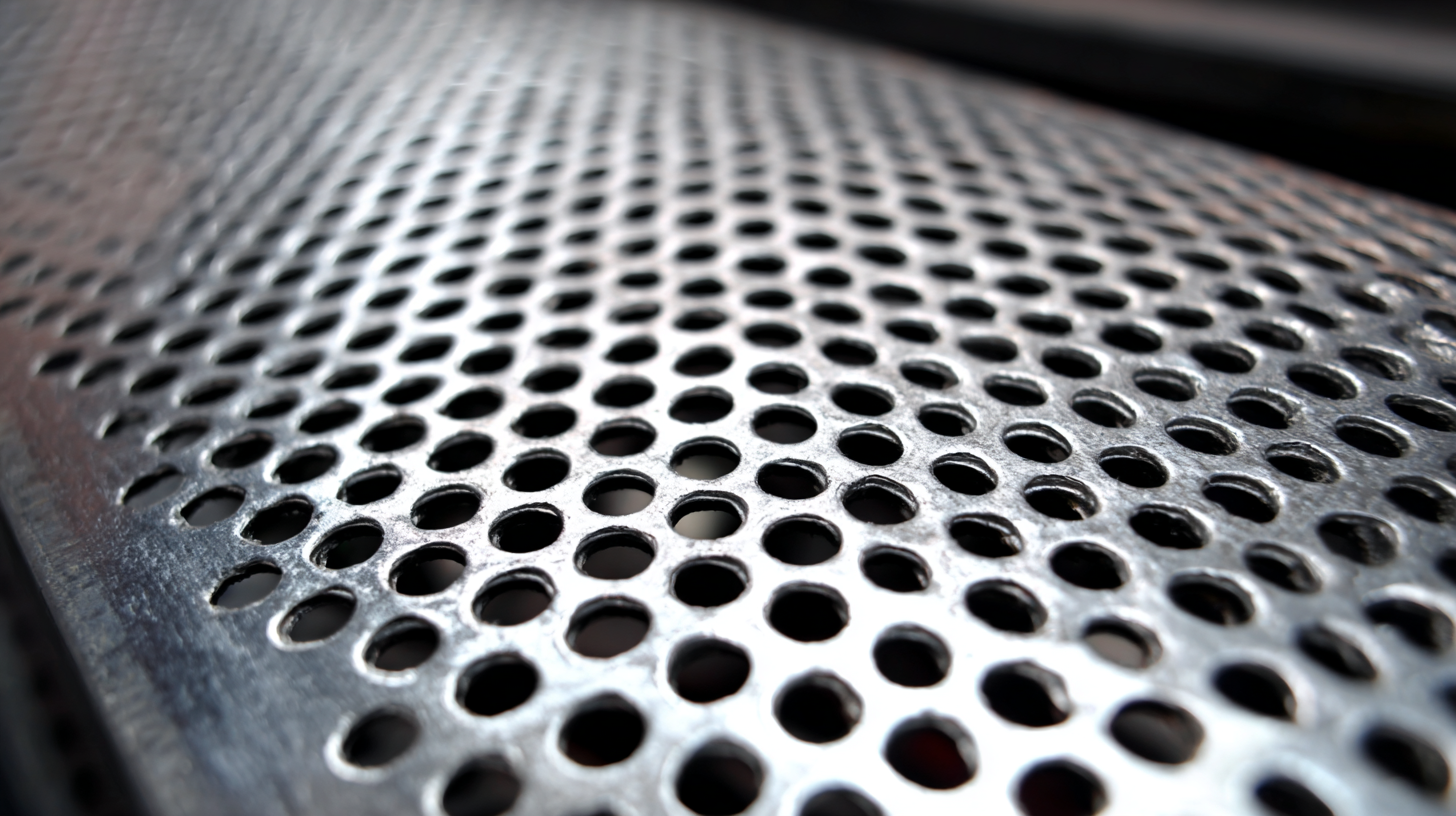

When embarking on a project that requires durable and versatile materials, choosing the right Stainless Steel Perforated Sheet is crucial for both functionality and aesthetics. According to a report by Grand View Research, the global market for perforated metals is expected to reach USD 2.75 billion by 2025, driven by the growing demand in various industries such as construction, automotive, and manufacturing. The unique properties of stainless steel, including corrosion resistance and strength, make it an ideal choice for applications ranging from architectural panels to filtration systems. However, with various specifications, hole patterns, and gauges available, selecting the appropriate perforated sheet can be challenging. This guide aims to provide insights into the key factors to consider, ensuring that you make an informed decision that aligns with your project requirements.

When selecting the right stainless steel perforated sheet for your project, it is crucial to understand the various types available in the market. Stainless steel perforated sheets are classified based on factors like hole size, thickness, and material grade. The most common grades include304, 316, and 430, each offering unique properties tailored for specific applications. For example, 304 stainless steel is widely used in food processing due to its excellent corrosion resistance, while 316 is preferred in marine environments for its superior durability against chlorides.

Tips: Before finalizing your choice, consider the environment in which the perforated sheet will be used. For outdoor applications, opt for higher-grade materials like 316 stainless steel to prevent rust and degradation.

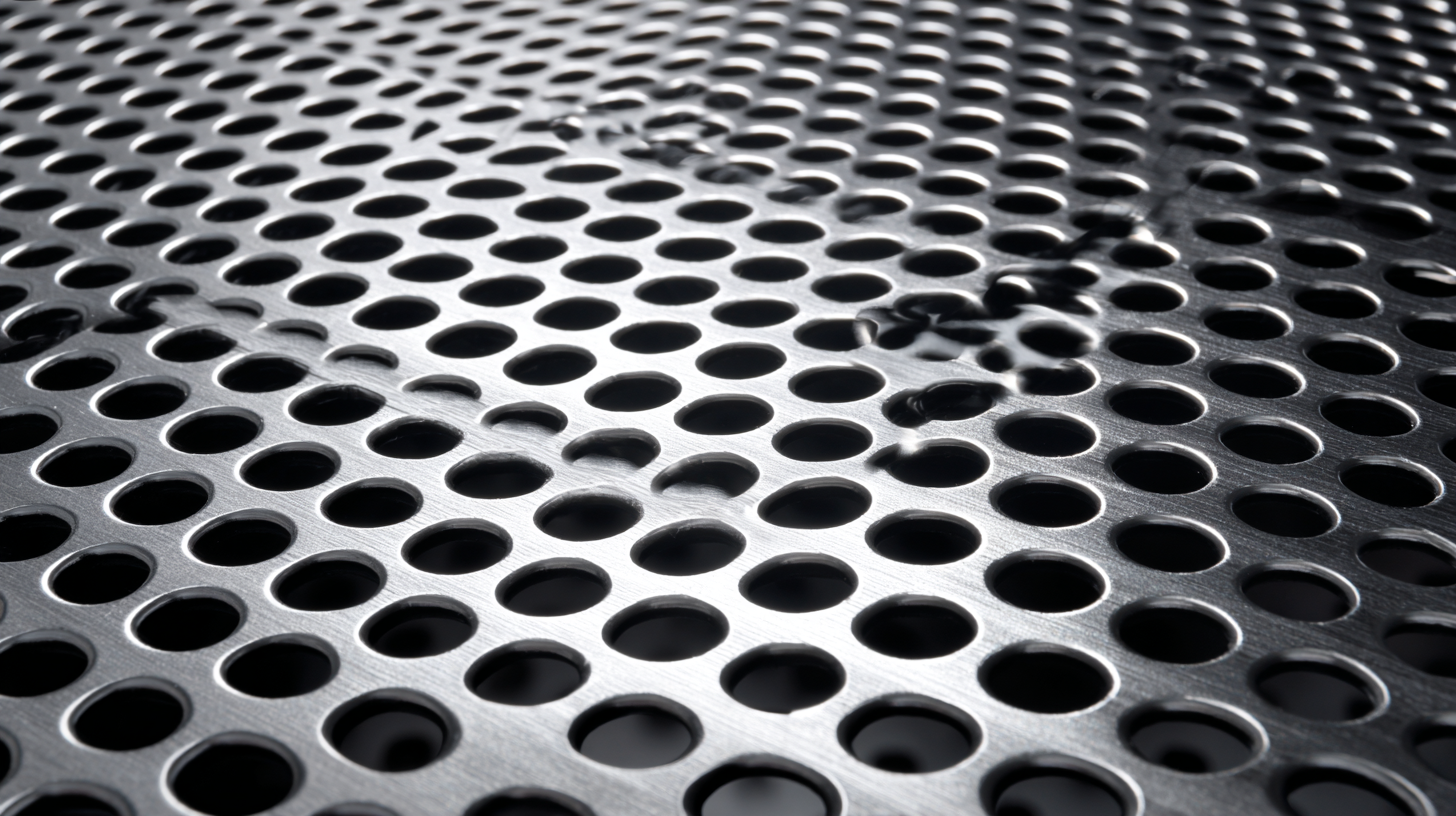

In terms of hole patterns and sizes, standard options include round, square, and slotted holes, with varying open areas. Industry reports indicate that sheets with an open area of 40-75% offer a balance between strength and airflow, making them popular for architectural applications. Custom perforation patterns are also available, allowing for tailored solutions that meet specific design needs.

Tips: Always consult technical specifications and, if possible, request samples to ensure the selected perforated sheet will perform as required in your project's context.

When selecting a stainless steel perforated sheet for your project, several key factors should be considered to ensure optimal performance and suitability. First, it is essential to determine the specific function the perforated sheet will serve. For instance, will it be used for aesthetic purposes, ventilation, or filtration? Understanding the primary function can guide decisions regarding hole size, shape, and pattern, which directly affect airflow, light transmission, and overall appearance.

When selecting a stainless steel perforated sheet for your project, several key factors should be considered to ensure optimal performance and suitability. First, it is essential to determine the specific function the perforated sheet will serve. For instance, will it be used for aesthetic purposes, ventilation, or filtration? Understanding the primary function can guide decisions regarding hole size, shape, and pattern, which directly affect airflow, light transmission, and overall appearance.

Another important factor is the material thickness and grade of the stainless steel. Different projects may require distinct mechanical properties, such as corrosion resistance or strength. Common grades like 304 and 316 provide varying levels of durability and resistance to environmental factors, making it critical to choose the right one based on the project location and expected exposure to elements. Additionally, consider the sheet's finish, as options like brushed or polished can impact both functionality and visual appeal. Ultimately, a thoughtful approach to these elements will help ensure that the selected perforated sheet effectively meets the demands of your project.

When selecting a stainless steel perforated sheet for your project, evaluating the hole size and pattern is crucial for optimal performance. The hole size directly influences the sheet's functionality, affecting airflow, liquid drainage, and even structural integrity. Larger holes may be suitable for applications requiring maximum flow, but they can compromise strength. Conversely, smaller holes can provide better support and filtration but may restrict airflow and drainage. Thus, it’s essential to consider the specific requirements of your application when determining the appropriate hole dimensions.

The pattern of perforation also plays a significant role in the sheet's overall effectiveness. Various patterns, such as staggered, straight, or designer arrangements, can influence both aesthetic appeal and functionality. A staggered pattern, for example, can enhance airflow compared to a standard arrangement, making it ideal for ventilation applications. Additionally, the uniformity of the pattern can impact visual uniformity in architectural designs. Assessing both these aspects—hole size and pattern—ensures that the stainless steel perforated sheet will meet the criteria necessary for your particular project, enhancing both performance and appearance.

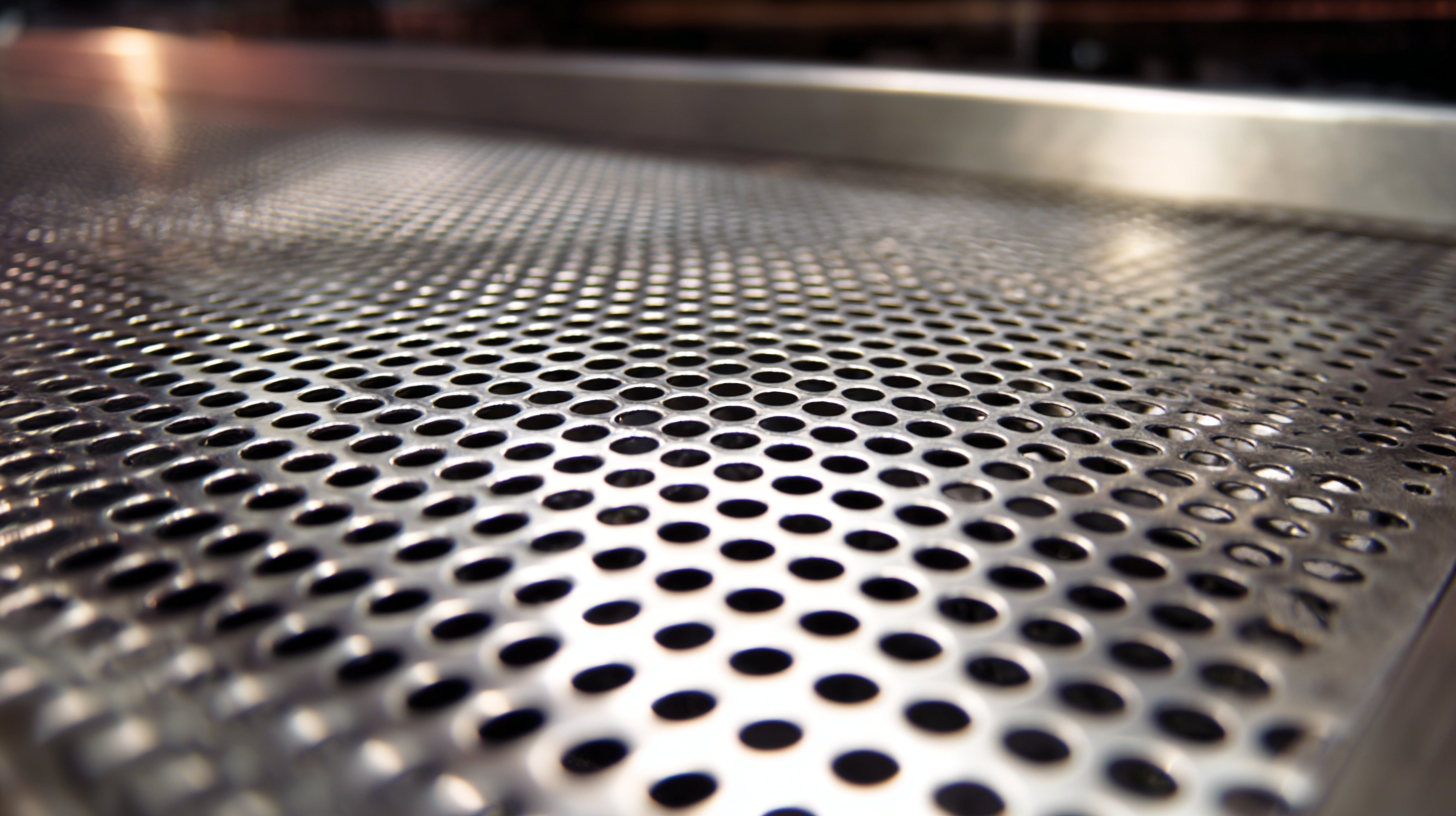

When selecting a stainless steel perforated sheet for your project, understanding material thickness is crucial as it directly impacts durability and performance. According to a report by the International Stainless Steel Forum (ISSF), the thickness of the sheet can significantly affect its resistance to wear, structural integrity, and lifespan, especially in demanding environments. Generally, thicker sheets, such as those exceeding 2mm, are recommended for applications requiring high durability, such as industrial flooring or architectural facade systems.

In addition, a study by the Metal Construction Association highlights that increased thickness contributes not only to strength but also to the ability to withstand environmental stressors like corrosion and mechanical impact. For instance, sheets with a thickness of 3mm or more demonstrate a 40% greater resistance to deformation compared to their thinner counterparts in high-load scenarios. Choosing the right thickness aligns with specific project requirements, ensuring that the perforated stainless steel sheet not only meets aesthetic needs but also endures the test of time in varied conditions.

Stainless steel perforated sheets are versatile materials used across various industries, owing to their durability and aesthetic appeal. Common applications include architectural design, where they can be seen in facades, ceilings, and railings. They also serve critical purposes in filtration systems in the food and beverage industry, providing strength and resistance to corrosion while allowing for efficient flow. Moreover, these sheets find their way into automotive and aerospace sectors, where weight reduction and structural integrity are paramount.

When choosing the right stainless steel perforated sheet, consider the hole size and pattern, as this significantly impacts functionality. For instance, larger holes may be necessary for ventilation, while smaller holes are better suited for filtration. Additionally, evaluate the sheet’s thickness based on your project requirements; thicker sheets provide added strength but may be heavier and harder to work with.

Tip: Always review the specifications and load-bearing capacity of the perforated sheets before making a final choice. This ensures that you select a sheet that meets both your aesthetic and functional needs seamlessly.

| Application | Common Use Case | Material Thickness (mm) | Hole Size (mm) | Sheet Size (mm) |

|---|---|---|---|---|

| Architectural | Facades, Partitions | 1.5 | 8 | 2000 x 1000 |

| Industrial | Screens, Filters | 2.0 | 5 | 3000 x 1500 |

| Safety | Gratings, Handrails | 3.0 | 10 | 2500 x 1000 |

| Acoustic | Sound Barriers, Ceiling Panels | 1.0 | 6 | 2400 x 1200 |

| Food Processing | Screens, Trays | 2.5 | 4 | 2000 x 1000 |