When embarking on a project that requires precision and efficiency, selecting the right material is paramount. Among various options, the **Stainless Perforated Sheet** stands out due to its versatility, aesthetic appeal, and robust mechanical properties. According to a recent industry report by the Metal Processing Association, the demand for stainless perforated sheets has grown by over 15% in the past year, reflecting their increasing importance in fields such as architecture, automotive, and filtration systems.

Industry expert Dr. Helen Carter, a leading authority in material selection and design, emphasizes the significance of this choice. She states, “Choosing the right stainless perforated sheet can dramatically affect the performance and aesthetics of a project.” This statement highlights the necessity of understanding the unique attributes of stainless perforated sheets, including different hole patterns and sizes, thickness variations, and material grades.

As we delve deeper into the intricacies of selecting an ideal stainless perforated sheet, it becomes clear that careful consideration can lead to enhanced functionality and long-term durability for various applications. By dissecting key factors such as load-bearing capacity, corrosion resistance, and visual appeal, we can make informed decisions that align with project requirements and industry standards.

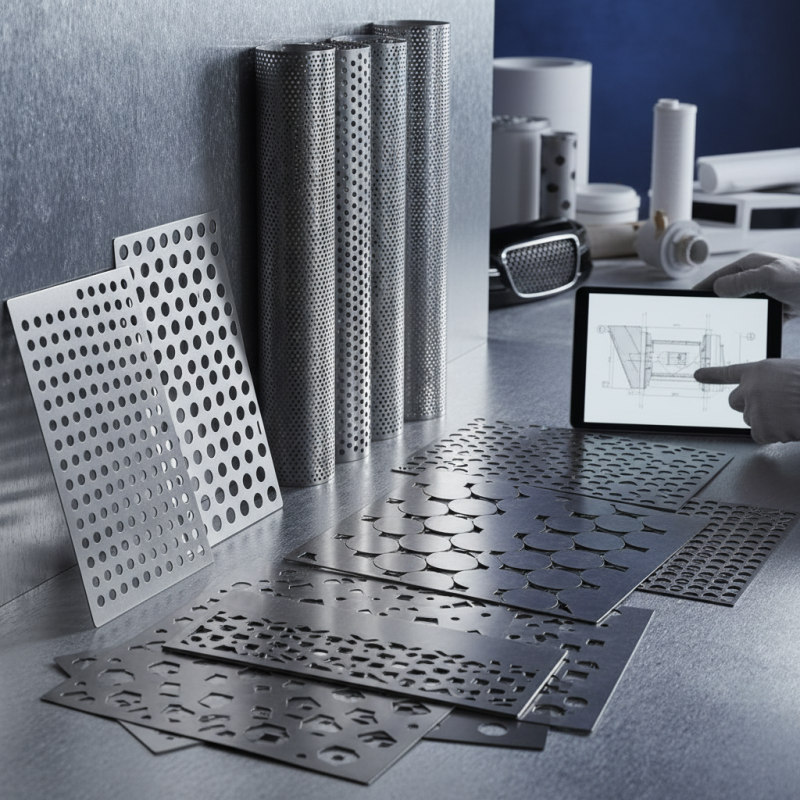

Stainless perforated sheets are versatile materials commonly used in various industries due to their strength, durability, and aesthetic appeal. Understanding the basics of these sheets is crucial for selecting the right type for your project. Typically made from stainless steel, these sheets feature numerous holes punched in a specific pattern, which can significantly enhance airflow, reduce weight, and allow for light penetration while maintaining structural integrity. According to a report from the Global Industry Analysts, the stainless steel perforated sheet market is projected to reach over $3 billion by 2027, reflecting its growing importance across sectors like construction, automotive, and food processing.

When considering the selection of stainless perforated sheets, it’s essential to evaluate factors such as hole size, thickness, and material grade. Hole sizes can range from tiny, precision cuts for filtration applications to larger holes for aesthetic designs or weight reduction. The thickness is often determined by the load and stress requirements of the application, with common gauges ranging from 16 to 25. Additionally, different grades of stainless steel, such as 304 and 316, provide varying degrees of corrosion resistance, making certain grades suitable for harsher environments like marine applications. According to the American Society for Testing and Materials, choosing the appropriate specifications can enhance the performance and longevity of the material, ensuring it meets the demands of the intended use.

| Dimension (mm) | Hole Size (mm) | Material Thickness (mm) | % Open Area | Application |

|---|---|---|---|---|

| 1000 x 2000 | 10 | 1.5 | 30 | Architectural Features |

| 1200 x 3000 | 5 | 2.0 | 25 | Screens and Grills |

| 1500 x 3000 | 8 | 1.0 | 20 | Industrial Applications |

| 1000 x 1000 | 12 | 1.5 | 35 | Acoustic Panels |

| 2000 x 1000 | 15 | 2.5 | 40 | Fencing Systems |

When selecting the right stainless perforated sheet for your project, understanding the key factors specific to your requirements is essential. First, consider the intended application of the sheet. Different projects may demand varying levels of strength, durability, and corrosion resistance. For instance, an industrial application may require high durability and specific hole patterns to facilitate airflow or material flow, while a decorative application might prioritize aesthetic qualities and a finer finish.

Another critical factor is the material specification itself. Stainless steel comes in various grades, each offering distinct properties. Assess the environmental conditions the sheet will face, such as exposure to chemicals, moisture, or extreme temperatures. This analysis will guide you in selecting the appropriate grade that balances performance and cost-effectiveness.

Additionally, the thickness of the sheet and the size and pattern of the perforations play a significant role in the overall functionality and appearance of the end product. Prioritize these elements based on your project's specific requirements to ensure optimal results.

When selecting the right stainless perforated sheet for your project, the material grade plays a critical role in determining performance and durability. Stainless steel is categorized into several grades, each offering unique properties tailored to specific applications. For example, grades 304 and 316 are commonly used in various industries due to their excellent corrosion resistance and formability. According to the Steel Recycling Institute, approximately 70% of stainless steel is recycled, making it not only a durable choice but also an environmentally friendly option.

The choice between 304 and 316 grades often depends on the project environment. Grade 304 is ideal for general applications exposed to mild corrosive environments, whereas grade 316 is recommended for more aggressive settings, such as marine or chemical applications, owing to its increased molybdenum content that enhances its resistance to chloride exposure. A report from the American Society of Metals indicates that 316 stainless steel can withstand pitting and crevice corrosion significantly better than 304 in saline conditions, making it suitable for applications like food processing and pharmaceutical manufacturing.

Evaluating these grades requires an understanding of the specific mechanical properties needed for the application. The tensile strength, yield strength, and elongation values of the chosen material should align with load requirements and potential impact considerations. For instance, grade 316 typically exhibits higher tensile strength than grade 304, making it a better option for structural applications where strength is paramount. Therefore, a thorough assessment of the project's environmental factors and mechanical demands will guide you toward the optimal stainless perforated sheet grade to ensure longevity and functionality.

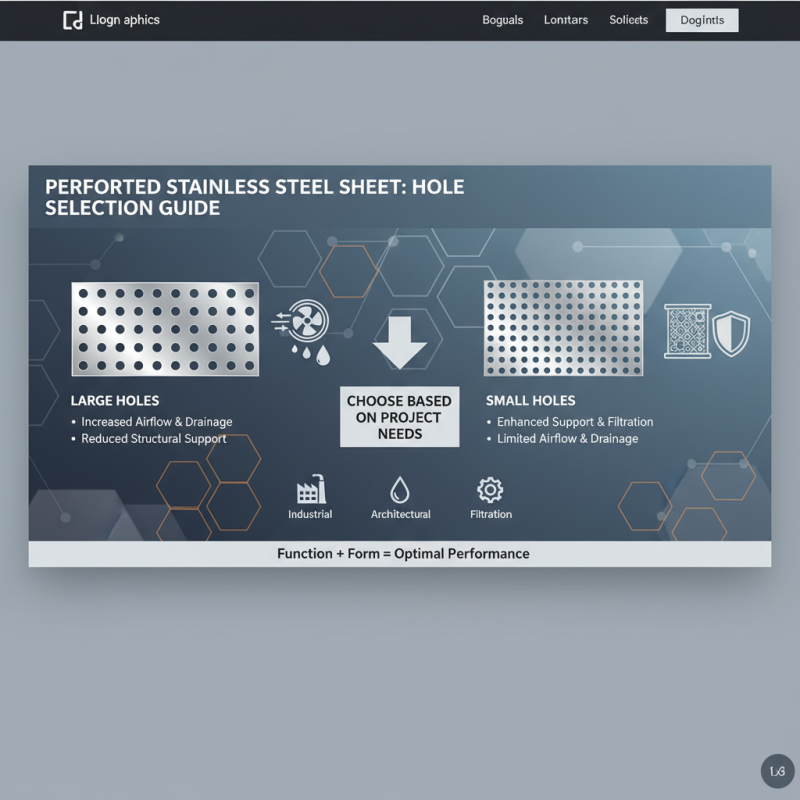

When selecting a stainless perforated sheet for your project, the hole size and configuration play a crucial role in ensuring the material meets your specific requirements. The hole size affects factors such as airflow, drainage, and load-bearing capacity. For instance, larger holes can provide greater ventilation and drainage but may compromise structural integrity, whereas smaller holes offer support and filter capability. Thus, you must evaluate the functional needs of your project to determine the optimal hole size.

In addition to size, the configuration of the holes is equally important. Common patterns include staggered, straight, and decorative designs, each serving different aesthetic and functional purposes. Staggered holes can increase strength and reduce weight, making them ideal for applications that require both durability and efficiency. On the other hand, straight patterns may be preferred for specific design aesthetics or to facilitate uniform filtration. By carefully considering both the size and configuration of the holes, you can select a stainless perforated sheet that not only fulfills practical requirements but also enhances the overall design of your project.

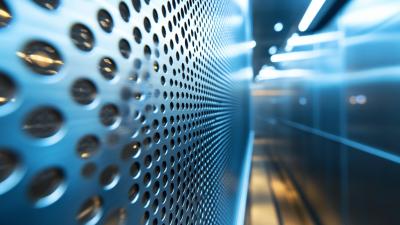

When selecting a stainless perforated sheet for your project, the finish and aesthetic aspects are paramount to ensuring that the final application meets both functional and visual expectations. The surface finish not only contributes to the durability and corrosion resistance of the material but also significantly influences its overall appearance. According to a report by the International Stainless Steel Forum, the demand for aesthetically pleasing finishes in architectural applications has increased by over 20% in the last five years, highlighting the importance of aesthetics in material selection.

Moreover, considering the various finishes available—such as brushed, polished, and matte—can enhance the design appeal of your project. A brushed finish offers a contemporary look that is often favored in modern architectural structures, while a polished finish adds a more reflective quality, making it suitable for decorative applications. Additionally, environmental factors, such as exposure to elements or cleaning methods, further dictate the choice of finish. In industrial settings, a more rugged finish may be required for durability, whereas retail environments might benefit from a highly polished sheet that enhances visual merchandise appeal.

Selecting the right finish not only defines the aesthetic character of your project but can also impact the material's performance. A study by the World Steel Association reveals that the right finish can increase the lifespan of stainless steel components by up to 30%, demonstrating the crucial intersection of aesthetics and functionality in choosing the appropriate perforated sheet for your specific needs.