Choosing the right Perforated Steel Sheet can be challenging. Various factors influence your decision. These include the sheet's size, hole pattern, and thickness.

Perforated Steel Sheets come in many designs. Some are more suitable for specific applications. For example, a sheet with larger holes may work better for ventilation. However, smaller holes may be needed for filters. It's essential to think about the intended use.

Sometimes, the process feels overwhelming. You might wonder if you've made the best choice. It's normal to question your decisions. Take a moment to reflect on your priorities. Analyze your needs carefully. This approach ensures you select the right Perforated Steel Sheet for your project.

Perforated steel sheets are widely used in various industries due to their strength and versatility. They are made by punching holes into steel sheets, creating a range of patterns and hole sizes. This allows for different applications, from filtration systems to architectural designs. Their lightweight nature makes them easy to handle, but choosing the right sheet can be tricky.

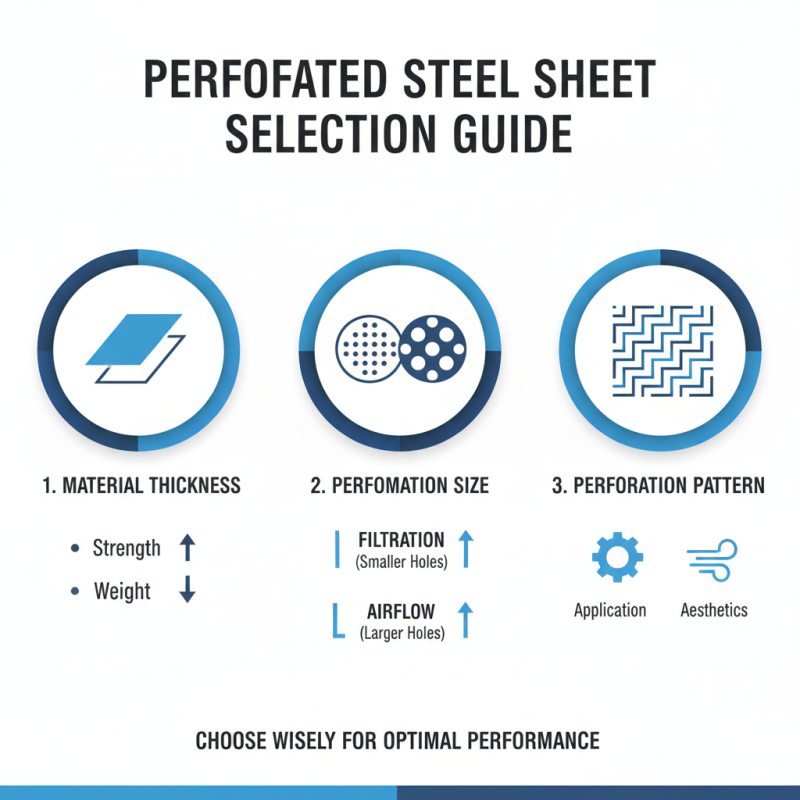

Consider the purpose of your project when selecting perforated steel. For example, a project requiring airflow might need larger holes, while decorative applications might favor smaller, intricate patterns. Additionally, think about material thickness. Thicker sheets offer more durability but can weigh more and be harder to work with. Some projects could benefit from custom hole shapes, which may not be standard.

Don't overlook factors like finish and corrosion resistance. If the sheet will be exposed to harsh conditions, a protective coating is essential. You might also find that costs increase with customization. Balancing your budget with your project's needs can be a daunting task. In some cases, you might need to revise your design to accommodate material constraints. It’s all part of finding the perfect fit for your project.

Choosing the right perforated steel sheet involves several key factors. Material thickness is essential. Thicker sheets provide more strength, while thinner ones reduce weight. Consider your project's requirements carefully. Perforation size and pattern also affect performance. Smaller holes provide better filtration, whereas larger holes offer greater airflow.

Tips: Think about the intended use. Are you making partitions or filters? Each application may require different specifications. Evaluate how aesthetics fit into your decision. A visually appealing design offers more than just function.

Durability is another crucial factor. Corrosion resistance matters, especially in harsh environments. Ensure that the surface finish aligns with your project's needs. This can require some trial and error to find the most suitable type.

Ultimately, budgeting plays a role too. High-quality materials often come at a cost. Weigh the benefits against the expense. Don't rush your decision; this is a significant investment.

When selecting a perforated steel sheet, understanding different perforation patterns is key. Circular holes are common. They provide good airflow and drainage. Square holes, on the other hand, can support heavy loads. They also allow large amounts of light to pass through. Triangular patterns create unique aesthetics. These are suitable for artistic projects or modern architecture.

Tips: Consider the main function of your project. If you need ventilation, choose a design with larger holes. For noise reduction, smaller holes are better. Analyze the load-bearing requirements. Patterns should cater to structural integrity as well.

Various shapes influence appearance and performance. Custom shapes blend functionality with design. However, not every pattern fits every need. Take time to research how different patterns perform under specific conditions. A poorly chosen perforation can lead to failure, affecting your overall project success.

When evaluating material thickness and sheet size for your perforated steel sheet needs, start by considering your project requirements. Thickness is crucial. Thicker sheets offer more strength. They can withstand heavier loads. However, they might be more challenging to work with. Lighter sheets are easier to manipulate but may not hold up under stress. Think about the environment too. If your project faces harsh conditions, thicker materials could be a better choice.

Next, focus on the size of the sheets. Measure the specific area you plan to cover. Optimal dimensions can reduce waste. But, larger sheets may require special handling. Additionally, smaller sheets can be easier to transport. Take into account how you'll cut or shape the sheets. Precision in size is vital, as poorly cut sheets can lead to project delays. Be prepared to rethink your choices if initial measurements don't align with your end goals. Adjustments may be necessary as you progress. Each step can teach you something new about material selection.

| Material Thickness (mm) | Sheet Size (mm) | Hole Diameter (mm) | Open Area (%) | Weight (kg/m²) |

|---|---|---|---|---|

| 1.0 | 1000 x 2000 | 5.0 | 30 | 7.85 |

| 1.5 | 1200 x 2400 | 6.0 | 35 | 11.79 |

| 2.0 | 1500 x 3000 | 7.0 | 40 | 15.68 |

| 3.0 | 2000 x 4000 | 8.0 | 45 | 23.43 |

When choosing perforated steel sheets, cost is a critical factor. Prices can vary significantly based on material thickness, hole size, and sheet dimensions. A recent industry report suggests that the average cost of perforated steel ranges from $1.00 to $5.00 per square foot. This cost can increase with custom designs or larger volume orders. It's essential to estimate your total needs to avoid overspending.

Supplier options also play a key role in your project’s success. Research shows that local suppliers often provide better shipping rates and quicker delivery times. However, larger manufacturers may offer competitive pricing and a broader range of options. Collecting quotes from multiple suppliers can help you assess price variations. It’s crucial to evaluate the quality of materials as well. Some suppliers may cut costs on raw materials, leading to a decrease in durability. Always check reviews and past projects to ensure you're making a sound choice.

Considering these factors can be overwhelming. A balance between cost and quality is necessary. You may find low-cost sheets that compromise on performance. Or, you could pay a premium without understanding their value. Analyzing your specific needs will yield the best outcomes.