In the world of industrial applications, selecting the right materials is crucial for ensuring efficiency and durability. One such material, Perforated Stainless Steel Mesh, has gained significant attention due to its unique properties and versatility. According to a report by Grand View Research, the global stainless steel market size was valued at USD 126.7 billion in 2020 and is expected to expand at a compound annual growth rate (CAGR) of 6.6% from 2021 to 2028. This growth parallels the rising demand for perforated metal products, which are widely used in construction, automotive, and filtration applications. The ability to customize hole patterns, sizes, and sheet thicknesses makes Perforated Stainless Steel Mesh an ideal choice for a variety of industries. As such, understanding how to choose the right specifications is essential for maximizing performance and longevity in its intended use.

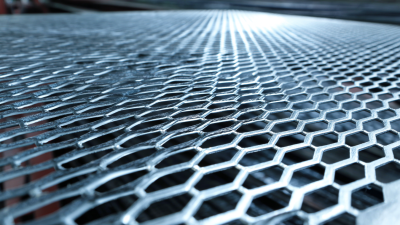

When selecting perforated stainless steel mesh, it is essential to understand the various types and their distinct characteristics to ensure optimal performance for specific applications. Common types of perforated stainless steel mesh include standard hole, slotted, and decorative patterns. Each pattern offers unique benefits: standard hole meshes are ideal for filtration and ventilation, slotted meshes enhance structural integrity while allowing for greater airflow, and decorative patterns can add aesthetic value to architectural projects.

Additionally, the choice of hole size and spacing plays a crucial role in determining the mesh’s functionality. Smaller holes provide better filtration, while larger openings are suited for applications requiring high flow rates. The gauge or thickness of the stainless steel also influences durability and strength; thicker materials are more robust and better suited for heavy-duty applications, while thinner gauges are often used in less demanding settings. Understanding these factors will guide users in selecting the right perforated stainless steel mesh to meet their specific needs effectively.

This chart illustrates the various specifications of perforated stainless steel mesh based on hole size and sheet thickness, showing their primary applications in different industries.

When selecting perforated stainless steel mesh, there are several key specifications to consider that can significantly impact the performance and suitability of the material for your specific application. First and foremost, the gauge of the mesh is crucial; it determines both strength and flexibility. Thicker gauges offer enhanced durability, making them ideal for heavy-duty applications, whereas thinner gauges may be suitable for less demanding uses where weight and cost are more critical.

Another important specification is the hole size and pattern. The dimensions of the openings will affect airflow, filtration efficiency, and aesthetic qualities of the mesh. Depending on the intended use, whether for architectural features or industrial filtration, you may require different hole sizes and arrangements. Additionally, consider the material grade of the stainless steel itself. Higher-grade materials, like 316 stainless steel, provide better corrosion resistance, making them preferable for outdoor or marine environments. By carefully evaluating these specifications, you can ensure that the chosen perforated stainless steel mesh meets the demands of your project effectively.

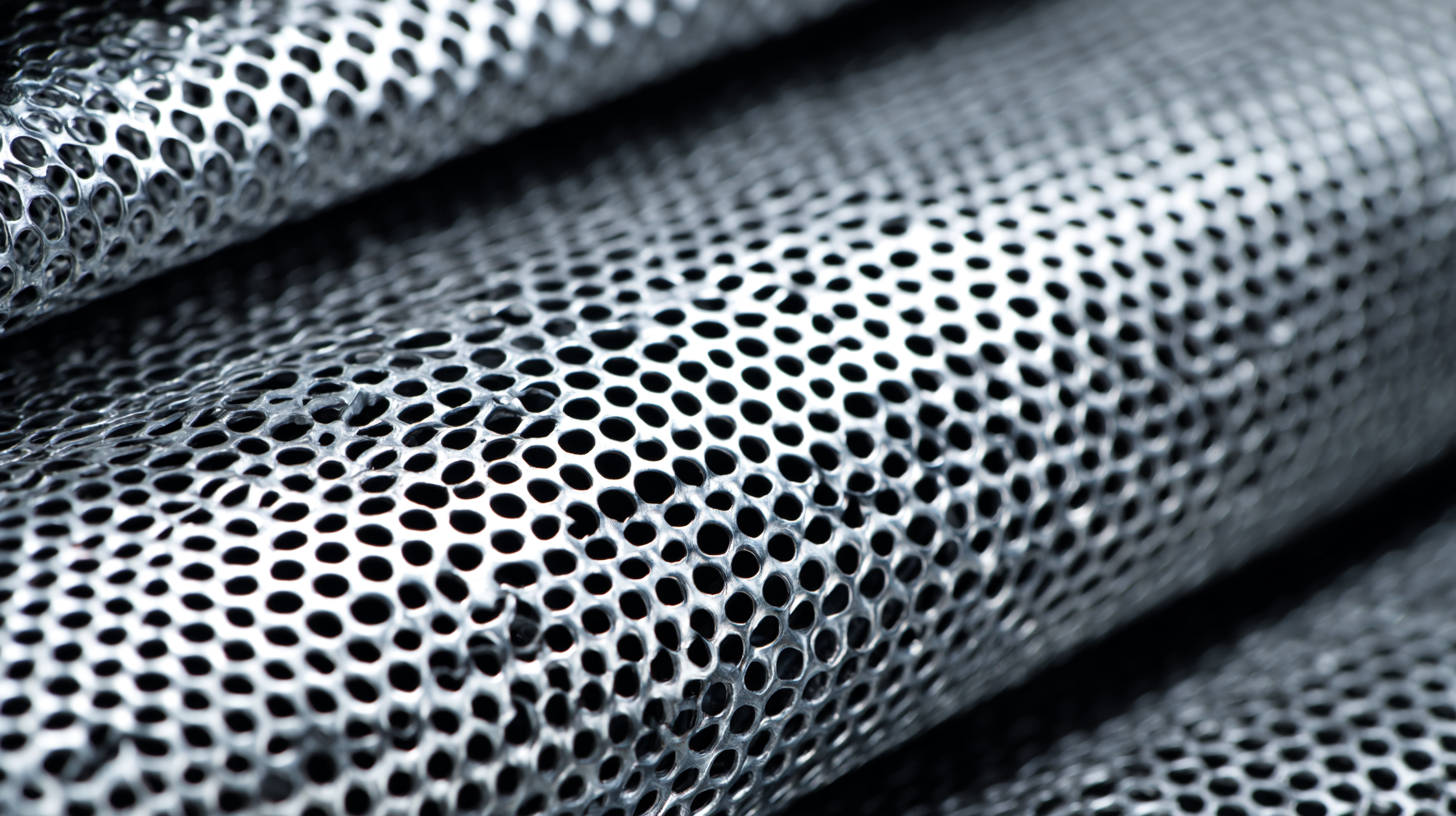

Perforated stainless steel mesh is highly versatile and finds applications across various industries due to its durability, corrosion resistance, and aesthetic appeal. In the automotive sector, for instance, holes are strategically punched to enhance airflow and reduce weight without compromising structural integrity. A report from ResearchAndMarkets stated that the automotive sector is projected to account for over 25% of the total industrial mesh market by 2025, highlighting the critical role that such mesh plays in manufacturing lightweight components.

In the food and beverage industry, perforated stainless steel mesh is essential for filtration and separation processes. Its hygienic properties make it ideal for use in equipment handling food products, as it can withstand high temperatures and rigorous cleaning protocols. According to a study by Grand View Research, the global food processing machinery market is expected to reach $88.6 billion by 2025, driven in part by innovations including the use of advanced mesh materials for enhanced efficiency and safety in production lines.

Moreover, in architectural applications, perforated stainless steel mesh is increasingly used for facade design, providing a blend of aesthetic appeal and functional attributes such as light diffusion and ventilation. The architectural mesh market is projected to grow at a CAGR of 6.3% through 2027, underscoring its rising popularity among designers looking to create sustainable and visually striking building exteriors.

When choosing perforated stainless steel mesh for various projects, several factors significantly influence the decision-making process. One primary consideration is the intended application, whether it be for architectural aesthetics, filtration systems, or safety barriers. According to a report by Market Research Future, the global perforated metal market is expected to witness a CAGR of 5.6% from 2020 to 2027, driven by increasing demand in construction and industrial sectors. Evaluating the mesh's hole pattern, size, and open area percentage is vital as it will impact airflow, visibility, and material strength.

Another critical factor is the type of stainless steel used, which can affect durability and corrosion resistance. Type 304 stainless steel is commonly preferred for its balance of strength and corrosion resistance in many environments, whereas Type 316 offers superior marine-grade protection, making it ideal for coastal applications. A study from the Stainless Steel World Conference highlights that projects utilizing high-quality stainless steel can reduce maintenance costs by up to 30% over their lifespan, emphasizing the importance of selecting the right material for specific conditions and longevity requirements.

When selecting perforated stainless steel mesh, maintenance and durability are key considerations that directly impact long-term performance. The stainless steel material itself is renowned for its resistance to corrosion, which makes it an ideal choice for various applications, including architecture and automotive industries. To ensure the mesh retains its integrity over time, regular cleaning is important to prevent the accumulation of debris and contaminants that could lead to staining or clogging. For instance, environments exposed to harsh weather or industrial pollutants may require more frequent maintenance to uphold optimal functionality.

In terms of durability, the thickness and type of perforation play significant roles in the lifespan of the stainless steel mesh. Thicker sheets, though potentially more expensive, offer enhanced strength and can withstand greater physical stresses. Additionally, the choice of perforation pattern impacts not only the aesthetic appeal but also the mesh's ability to filter or vent, depending on its intended use. As the market for perforated metal sheets is projected to grow to $5.3 billion by 2035, influenced by expanding demands in various sectors, investing in high-quality perforated stainless steel mesh with strong maintenance practices is essential to maximize its effectiveness across applications.

| Specification | Description | Applications | Maintenance Considerations | Durability |

|---|---|---|---|---|

| Sheet Thickness | Varies from 0.5mm to 5mm | Construction, HVAC | Regular cleaning recommended | Highly durable, resistant to rust |

| Hole Size | Ranges from 1mm to 30mm | Filtration, sieving | Ensure holes are free from obstructions | Excellent longevity under proper use |

| Operational Temperature | -200°C to 900°C | High-temperature applications, aerospace | Inspect for thermal expansion signs | Maintains strength at high temperatures |

| Finish Type | Polished, matte, or coated | Decorative, architectural uses | Use pH-neutral cleaners to avoid corrosion | Finish impacts long-term performance |