When embarking on a project that requires effective filtration and ventilation solutions, selecting the right materials is crucial for optimal performance. One such option that has gained significant attention in various industries is Perforated Screen Panels. According to a recent industry report by MarketsandMarkets, the global perforated metal market is projected to reach USD 3.3 billion by 2025, with a noteworthy CAGR of 5.7% from 2020 to 2025. This surge can be attributed to the increasing demand for customizable and efficient solutions across sectors such as construction, mining, and manufacturing.

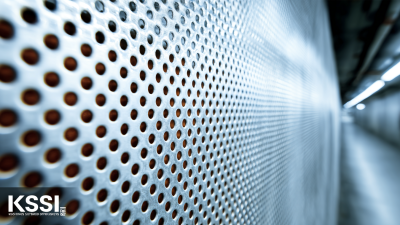

Perforated Screen Panels offer a practical blend of durability, aesthetic appeal, and functionality, making them a favored choice for architects and engineers alike. These panels provide enhanced airflow while maintaining structural integrity, which is essential in applications ranging from acoustic management to air filtration systems. Furthermore, the ability to choose from a variety of hole patterns and materials makes Perforated Screen Panels versatile, catering to diverse project requirements. As users strive to optimize their designs and improve operational efficiency, understanding how to select the best perforated screen panels becomes paramount to achieving successful outcomes.

Perforated Screen Panels offer a practical blend of durability, aesthetic appeal, and functionality, making them a favored choice for architects and engineers alike. These panels provide enhanced airflow while maintaining structural integrity, which is essential in applications ranging from acoustic management to air filtration systems. Furthermore, the ability to choose from a variety of hole patterns and materials makes Perforated Screen Panels versatile, catering to diverse project requirements. As users strive to optimize their designs and improve operational efficiency, understanding how to select the best perforated screen panels becomes paramount to achieving successful outcomes.

When selecting perforated screen panels for a project, it is essential to identify specific project requirements that can significantly influence both functionality and aesthetics. For instance, in architectural applications, such as the recent renovation of the fire escape stairs in North Sydney, perforated panels not only enhance the structure's visual appeal but also ensure compliance with safety regulations. This highlights the importance of integrating design with practical necessities like safety and durability.

Additionally, considerations such as acoustical performance and sustainability are pivotal. Emerging designs, particularly in urban environments, utilize perforated aluminum panels for their ability to blend functionality with modern architectural aesthetics. Projects like the Kiewit Luminarium showcase how these materials serve both as an artistic statement and a means to improve performance, such as enhanced ventilation and sound absorption. Understanding these diverse project needs allows architects and designers to choose the most suitable perforated screen panels, ensuring that they meet the specific requirements of their applications.

| Dimension | Material | Hole Shape | Hole Size | Application |

|---|---|---|---|---|

| 4' x 8' | Aluminum | Round | 1/4" | Architectural Elements |

| 3' x 6' | Stainless Steel | Square | 1/8" | Industrial Applications |

| 2' x 2' | Mild Steel | Hexagonal | 3/16" | Noise Control |

| 5' x 10' | Fiberglass | Custom Shapes | 1/2" | Ventilation |

When selecting perforated screen panels for your project, understanding the different materials available is crucial. Commonly used materials include aluminum, stainless steel, and carbon steel, each offering unique advantages. According to industry reports, aluminum is favored for its lightweight properties and corrosion resistance, making it suitable for outdoor applications. The Metal Construction Association indicates that aluminum perforated screens can last up to 30 years with minimal maintenance, making them a cost-effective choice in the long run.

On the other hand, stainless steel perforated panels are revered for their strength and durability. They are ideal for environments that require resistance to harsh chemicals or extreme temperatures. A survey from the American Institute of Steel Construction reveals that stainless steel panels have a higher strength-to-weight ratio than other materials, making them a preferred choice for industrial applications. Meanwhile, carbon steel offers a budget-friendly alternative without compromising on structural integrity, although it may require additional coatings to prevent rust. When choosing the right perforated screen panels, evaluating the specific demands of your project will guide you towards the most suitable material.

When selecting perforated screen panels for your project, the evaluation of hole patterns and sizes is crucial for achieving optimal performance. According to a report from the Geological Society, the efficiency of filtration systems can be significantly influenced by the parameters of the perforations. For instance, smaller hole sizes can enhance the filtering capability while ensuring that valuable materials are not lost. Industries that involve fine particle processing often prefer perforated panels with hole diameters between 0.5 mm to 2 mm to maximize efficacy without risking clogging.

Furthermore, the arrangement of holes plays a vital role in airflow dynamics and material conveyance. A study published in the Journal of Industrial Engineering indicated that staggered hole patterns can lead to a reduction in turbulence and enhance flow rates by up to 15%. When choosing your perforated screen panels, consider both the size and layout of the holes carefully to improve operational efficiency and ensure that the panels meet the specific needs of your project. Balancing these factors based on the application requirements is essential for achieving the best results.

When selecting perforated screen panels for your project, cost-effectiveness is a paramount consideration. Different materials and design options can significantly impact both initial investment and long-term operational costs. For instance, aluminum panels are lightweight and resistant to corrosion, making them a durable yet cost-efficient choice for outdoor applications. Conversely, steel panels, while potentially more expensive upfront, offer greater strength and longevity, which can lead to reduced replacement and maintenance costs over time.

Additionally, the manufacturing process plays a crucial role in determining the overall cost of the panels. Custom-made perforated screens may provide tailored solutions for specific needs but can drive up expenses. On the other hand, pre-manufactured panels available in standard sizes and designs can offer a more economical route, allowing for bulk purchasing discounts. Evaluating the balance between functionality, maintenance, and budget constraints is essential to choose the right perforated screen panels that deliver the best value for your project.

When selecting perforated screen panels, one of the most crucial factors to consider is their durability. The material of the panels plays a significant role in their longevity. Common materials such as stainless steel, aluminum, and coated metals offer varying degrees of strength and resistance to environmental factors. For instance, stainless steel panels are renowned for their corrosion resistance and structural integrity, making them ideal for outdoor applications. Understanding the specific conditions the panels will face—such as exposure to moisture, chemicals, or extreme temperatures—will help in determining the most suitable material.

Maintenance is another essential consideration in ensuring the performance and lifespan of perforated screens. Depending on the material and usage, maintenance needs can vary significantly. For instance, while aluminum panels might require regular cleaning to prevent oxidation, stainless steel forms a protective layer that reduces maintenance frequency. It is also essential to consider the panel's design and hole patterns, as some designs may accumulate more debris and require more thorough cleaning. An informed choice regarding both durability and maintenance can greatly enhance the efficiency and longevity of perforated screen panels in any project.