The selection of the best Perforated Metal Screen for your project involves a nuanced understanding of design, functionality, and material specifications. According to a recent report by the Metal Industries Research Association, the global market for perforated metal is projected to reach $2.5 billion by 2025, reflecting an increasing demand across various industries including construction, automotive, and electronics. As these sectors continue to expand, the need for high-quality perforated metal solutions remains crucial for optimizing performance and aesthetic appeal.

Industry expert Dr. Linda Hayes, a leading authority on material innovation, emphasizes the importance of taking time to evaluate your specific project requirements: "Choosing the right Perforated Metal Screen is not just about aesthetics; it’s about ensuring durability and functionality tailored to the application's needs." In light of this, the decision-making process should encompass factors such as hole size, thickness, and spacing to achieve the desired balance of light, air, and sound permeability, along with structural integrity. By understanding these variables, stakeholders can ensure that their choice of perforated metal screening not only meets the technical specifications but also enhances the overall design of the project.

Perforated metal screens are versatile components used in a variety of applications across different industries. These screens are made from sheets of metal that have been punctured with a series of holes, which can vary in size, shape, and spacing. The primary advantage of using perforated metal is its ability to provide both aesthetic appeal and functional advantages, including airflow, visibility, and light transmittance. Depending on the project requirements, perforated screens can be employed for architectural facades, decorative interior elements, and functional screens in industrial processes.

The applications of perforated metal screens are extensive. In architecture, they serve as effective sunshades, limiting direct sunlight while maintaining an open flow of air and light. In industrial settings, they can be used for filtering and separating materials, enhancing efficiency in processes such as air filtration or grain handling. Additionally, these screens can play a crucial role in noise reduction, acting as barriers that absorb sound in high-decibel environments. Understanding the specific requirements of your project, including load capacity, environmental durability, and aesthetic goals, is essential for selecting the right perforated metal screen to maximize its potential benefits.

When selecting the best perforated metal screen for your project, several key factors need to be considered to ensure optimal performance and suitability. First and foremost, the material type is crucial. Different metals offer varying levels of strength, corrosion resistance, and aesthetic appeal. For instance, stainless steel is known for its durability and resistance to rust, making it ideal for outdoor applications. In contrast, aluminum is lightweight and offers excellent corrosion resistance, which may be beneficial for specific design needs.

Another important factor to consider is the hole size and pattern of the perforated metal screen. The size of the holes will influence the flow of air, light, and sound through the screen, which is critical depending on its intended use. For applications like ventilation or acoustic panels, a finer hole size may be preferred. Additionally, the arrangement of the holes can affect both the functional aspects and the visual appeal of the screen. Custom patterns can enhance aesthetics while maintaining necessary performance requirements.

Finally, it’s essential to consider the thickness of the material and the overall design of the screen. Thicker materials generally provide more strength and durability but can also increase weight and cost. The design should align with the project’s specifications and whether it needs to offer structural support or be purely decorative. By evaluating these factors, you can make an informed decision that meets the demands of your specific project while ensuring longevity and functionality.

When selecting a perforated metal screen for your project, the choice of materials and coatings is critical for durability and functionality. Common materials used for perforated metal include stainless steel, aluminum, and mild steel, each offering unique advantages.

Stainless steel is known for its corrosion resistance and strength, making it ideal for outdoor and industrial environments. Aluminum, on the other hand, is lightweight and resistant to oxidation, which makes it suitable for applications where weight is a concern. Mild steel is typically more cost-effective, but it requires protective coatings to withstand harsh conditions.

Coatings significantly enhance the lifespan of perforated metal screens. Powder coating is a popular choice due to its aesthetic appeal and excellent durability. It provides a tough finish that resists scratches, fading, and chipping, making it particularly advantageous for decorative applications.

Similarly, galvanization offers excellent protection against corrosion, extending the screen's usability in corrosive environments. Additionally, specialized coatings like epoxy or polyurethane can be applied for further protection, ensuring that the perforated metal screens not only meet performance requirements but also maintain their appearance over time.

Selecting the right material and coating is essential for achieving long-lasting and effective results in your project.

When selecting a perforated metal screen for your project, the design and hole patterns play a crucial role in both functionality and aesthetics. According to industry reports, the choice of hole size and arrangement can significantly affect airflow, visibility, and light transmission in architectural applications. For instance, optimized hole patterns can enhance the acoustic performance of a space, leading to reductions in noise levels by as much as 50% in certain environments. This is essential for projects in urban areas or locations where sound control is paramount.

Aesthetic considerations are equally important, as perforated metal screens serve as both functional and decorative elements. The pattern you choose can create striking visual effects or harmonize with existing structures. Studies indicate that unique designs can improve the perceived value of a property by up to 20%. Designers often utilize common arrangements such as staggered or aligned patterns to achieve a modern look while maintaining the screen's structural integrity. By carefully balancing these functional and aesthetic aspects, you can create perforated metal screens that not only fit the technical requirements of your project but also enhance its overall appeal.

| Design Type | Hole Pattern | Material | Application | Aesthetic Appeal |

|---|---|---|---|---|

| Square Hole | Uniform grid | Aluminum | Architectural Screens | Modern and clean |

| Round Hole | Staggered pattern | Stainless Steel | Industrial Grates | Sleek and versatile |

| Slot Hole | Linear pattern | Mild Steel | Ventilation Screens | Contemporary and stylish |

| Custom Design | Variable sizes | Copper | Decorative Applications | Unique and artistic |

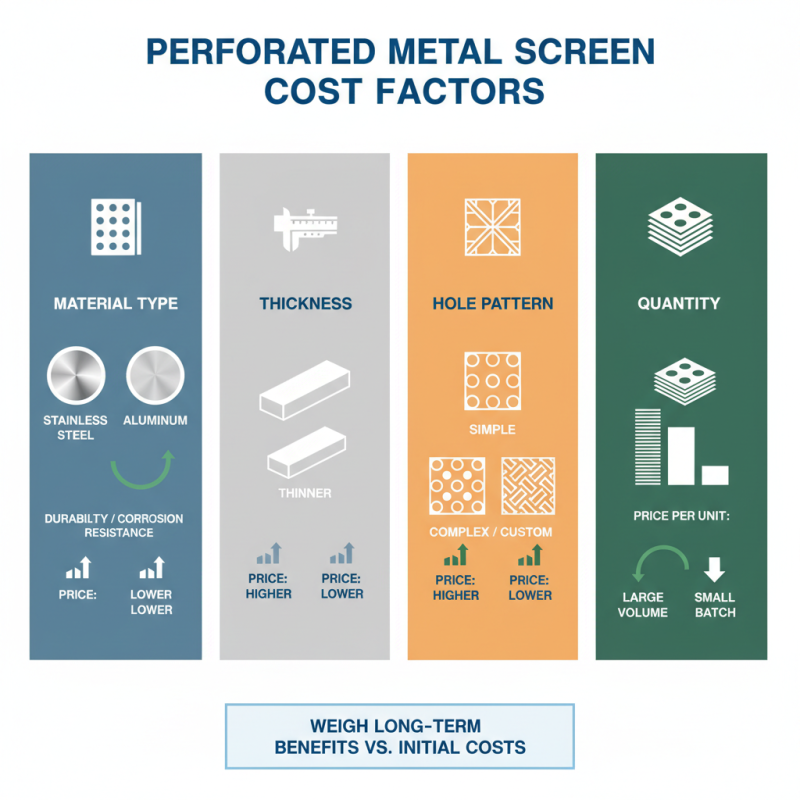

When selecting perforated metal screens for your project, considering cost is essential to ensure your budget aligns with your design goals. The price of perforated metal can vary significantly depending on factors such as material type, thickness, hole pattern, and quantity required. For instance, stainless steel might be more expensive than aluminum; however, its durability and corrosion resistance may justify the higher price for certain applications. It’s crucial to weigh the long-term benefits against the initial costs to make an informed decision.

Sourcing options for perforated metal screens can also impact the overall expenditure. Local manufacturers could offer competitive pricing and reduced shipping costs, while larger online suppliers might provide a broader range of customizable options. When exploring suppliers, consider obtaining quotes from multiple sources to compare prices and terms. Additionally, some manufacturers may offer bulk discounts, which can significantly lower costs for larger projects. Understanding these cost considerations and sourcing opportunities can ultimately help you choose the best perforated metal screen tailored to your project’s needs and budget.