Choosing the right Perforated Stainless Steel Mesh for your project is crucial to achieving optimal performance and aesthetics in various applications. With the global market for perforated metal poised to reach $2.6 billion by 2025, driven by its increasing use in construction, architecture, and industrial processes, understanding the specifications and benefits of different mesh types has never been more important.

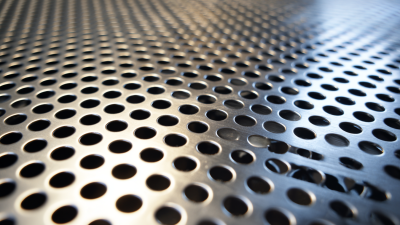

Perforated Stainless Steel Mesh, known for its durability and corrosion resistance, offers versatility that caters to diverse needs, from filtration systems to decorative facades. According to industry reports, selecting the appropriate perforation size, pattern, and material is essential in ensuring effective functionality and compliance with project requirements. By focusing on key considerations, you can enhance safety, efficiency, and longevity in your designs.

Perforated Stainless Steel Mesh, known for its durability and corrosion resistance, offers versatility that caters to diverse needs, from filtration systems to decorative facades. According to industry reports, selecting the appropriate perforation size, pattern, and material is essential in ensuring effective functionality and compliance with project requirements. By focusing on key considerations, you can enhance safety, efficiency, and longevity in your designs.

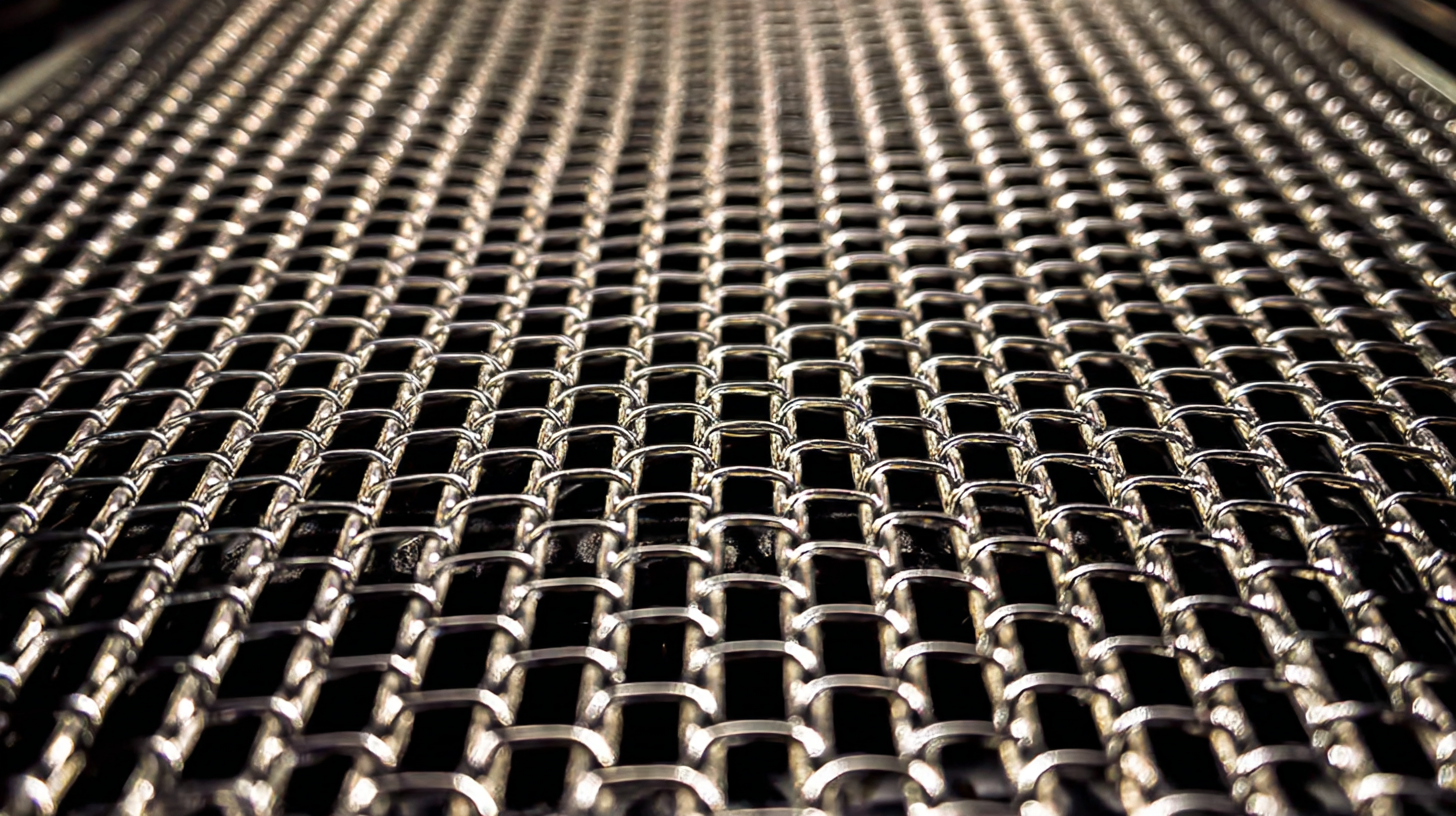

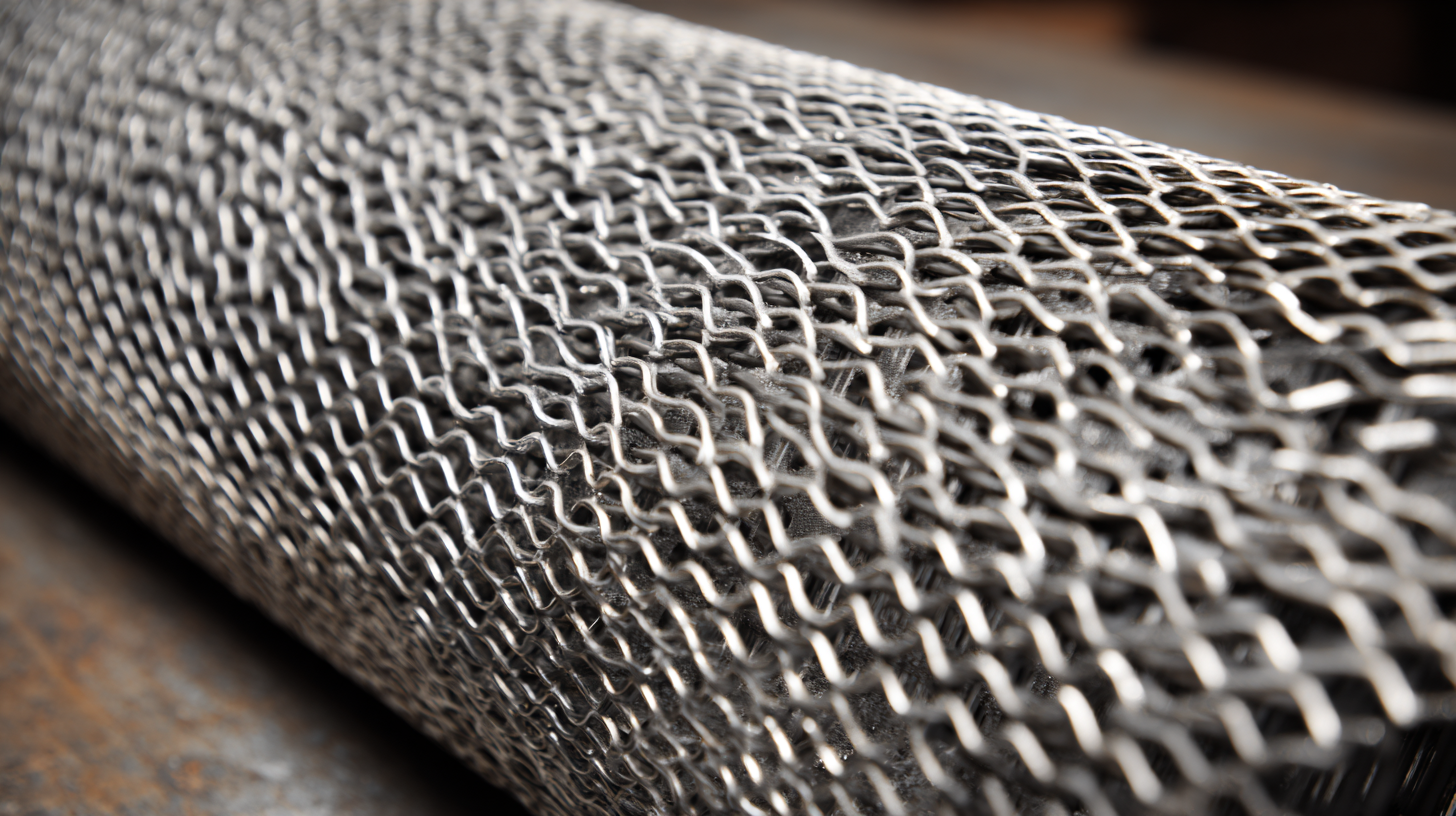

When selecting the right perforated stainless steel mesh for your project, it's essential to understand the different options available and their applications. Perforated stainless steel mesh is commonly used in various industries, including construction, automotive, and food processing. It offers a combination of strength, durability, and aesthetic appeal, making it a versatile choice for many things, from decorative elements to functional components.

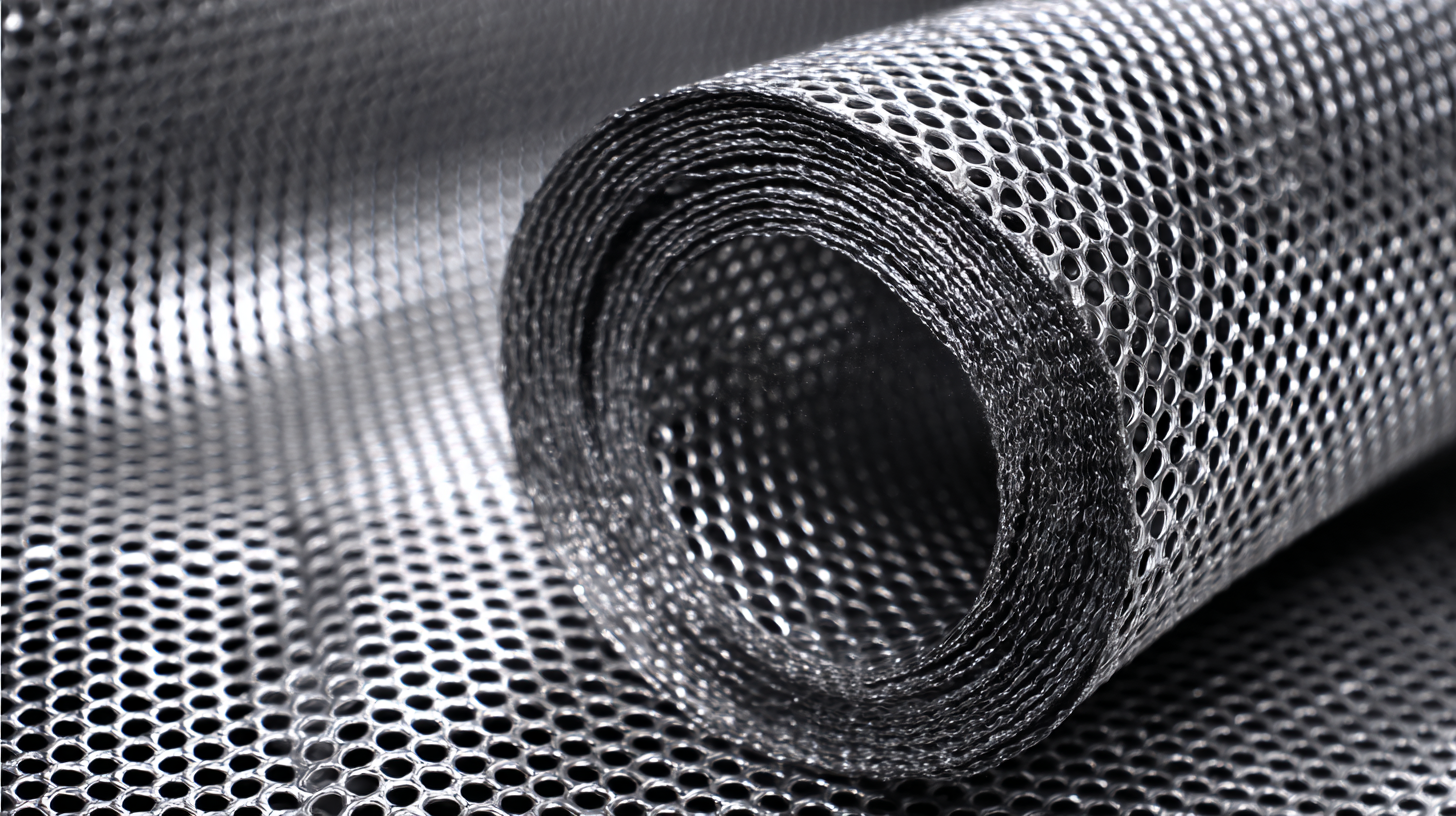

A crucial factor to consider is the hole size and pattern, which can significantly affect airflow, light penetration, and material visibility. Research indicates that different perforation patterns can influence not only performance but also the aesthetic qualities of the application. For instance, larger holes can enhance airflow in ventilation systems, while smaller perforations may be preferred in architectural applications where visual appeal matters. Industry reports suggest that choosing the right combination of hole size and thickness can increase product efficiency by over 30%, ensuring that you meet your project's specific requirements effectively.

When selecting the right perforated stainless steel mesh for your project, it’s crucial to evaluate your specific requirements regarding size, shape, and performance. The dimensions of the mesh will significantly affect its application. Ensure that you measure the area where the mesh will be installed, taking into account any obstructions or specific design features. This helps in avoiding unnecessary waste and ensuring a proper fit.

Shape is another critical factor to consider, as perforated stainless steel meshes come in various patterns and configurations. Depending on your project’s purpose, you may need a certain type of hole pattern for optimal airflow or aesthetic appeal. Choose the shape that aligns best with the functionality you desire, whether it’s for filtration, architectural design, or safety.

**Tips:**

1. Always prototype with a small section of the mesh to see how it integrates with your project.

2. Consult with suppliers to understand the strength and durability of different types of perforated stainless steel to ensure it meets your performance needs.

3. Consider the environment where the mesh will be used; factors like exposure to moisture or chemicals can influence the choice of material.

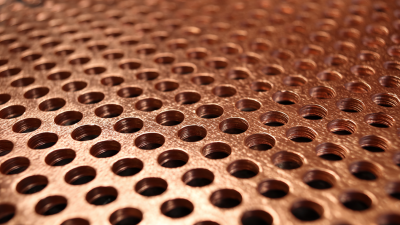

When selecting perforated stainless steel mesh for your project, the choice of stainless steel grade is crucial. Stainless steel is available in several grades, each with distinct properties, making it essential to consider the specific requirements of your application. For instance, 304 stainless steel is commonly used due to its excellent corrosion resistance and good formability, making it suitable for various environments, including indoor and outdoor applications. However, if your project involves exposure to harsher conditions, such as chemical processing or marine environments, opting for 316 stainless steel, which has enhanced corrosion resistance due to the addition of molybdenum, would be the wiser choice.

Additionally, it is important to assess the mechanical properties of the stainless steel grade. Factors such as tensile strength, elongation, and hardness can significantly influence the performance and durability of the mesh in your application. If strength and durability are paramount, then the high-performance stainless steel grades like 17-4 PH could be ideal, offering both resistance to corrosion and substantial strength. Therefore, understanding both the environmental conditions and the mechanical demands of your project will guide you in selecting the right grade of stainless steel for your perforated mesh needs.

When selecting perforated stainless steel mesh for your project, assessing hole patterns and configurations is vital for ensuring optimal functionality. The choice of hole shape, size, and arrangement directly influences the mesh's performance in applications such as filtration, ventilation, and aesthetic design.

According to the Industrial Mesh Association, a well-optimized hole pattern can improve airflow by up to 30%, enhancing the efficiency of ventilation systems in industrial environments.

Moreover, different projects may require specific configurations; for instance, round holes are commonly used in applications requiring even distribution and strength, while slotted holes can provide better drainage and reduced weight. A study by the American Society for Testing and Materials (ASTM) indicates that certain configurations can also affect the load-bearing capacity and structural integrity of the mesh. Understanding these parameters allows designers and engineers to tailor the mesh to their needs, ensuring that both modern aesthetics and functional performance are prioritized in their projects.

When selecting perforated stainless steel mesh for your project, cost considerations play a crucial role. According to a recent industry report by Grand View Research, the global stainless steel market is projected to reach approximately $200 billion by 2028, reflecting a growing demand for quality materials across various sectors. Understanding the price fluctuations in raw materials, manufacturing processes, and market availability can help you budget effectively. Typically, prices can vary significantly based on mesh size, gauge, and coating options, which can add anywhere from 10% to 30% to your overall material costs.

Sourcing reliable suppliers is equally important to ensure you receive quality products that meet your specifications. A report by MarketsandMarkets indicates that the rise in construction and automotive industries is driving the demand for stainless steel mesh. Therefore, it's advisable to partner with suppliers who have a proven track record and positive customer reviews. Additionally, engaging with suppliers who have certifications such as ISO 9001 can assure you of their commitment to quality standards. This not only helps in securing competitive pricing but also ensures timely delivery, which can be critical for project timelines.