When embarking on a project that requires the use of Perforated Metal Panels, making the right choice can significantly influence both the functionality and aesthetic appeal of your design. As industry expert John Smith, a leading architect in sustainable building design, puts it, “Choosing the correct perforated metal can enhance not only the visual impact but also the efficiency of the entire structure.” His insight highlights the importance of understanding the diverse applications and benefits of these versatile materials.

Perforated Metal Panels come in various shapes, sizes, and configurations, allowing for tailored solutions suitable for numerous environmental conditions and design goals. Whether it’s for architectural façade systems, noise control, or interior design elements, the myriad options available can meet specific project requirements. As such, knowing how to select the right panels is crucial for achieving the desired results while maximizing performance and durability.

In this article, we will delve into the essential factors to consider when selecting Perforated Metal Panels, including hole size, pattern, material type, and finish. By understanding these elements, project managers and designers can make informed decisions that not only satisfy aesthetic desires but also align with practical demands of their projects.

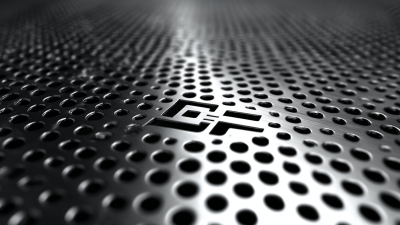

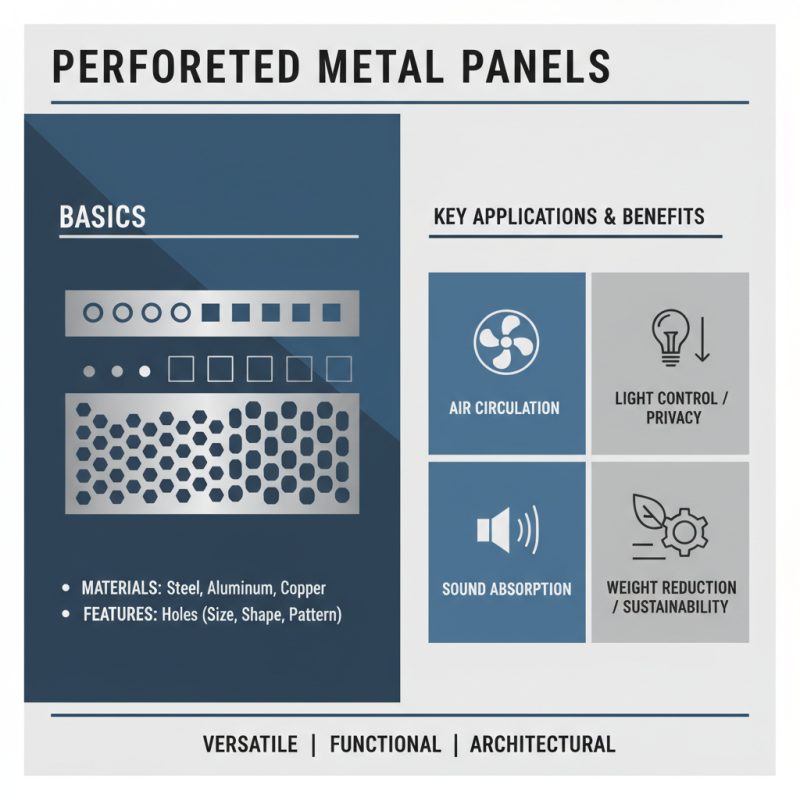

Perforated metal panels are innovative structural elements that combine aesthetic appeal with functionality. Understanding the basics of these panels is crucial for making informed decisions in a variety of projects, from architectural designs to industrial applications. Typically made from materials such as steel, aluminum, or copper, perforated panels feature a series of holes that can vary in size, shape, and pattern. This versatility allows them to serve multiple purposes, such as improving air circulation, reducing weight, controlling light penetration, and even enhancing sound absorption.

When selecting perforated metal panels for a project, it is essential to consider factors such as the panel's material, thickness, hole pattern, and finish. The choice of material affects the durability and maintenance of the panels, while the thickness can influence their strength and load-bearing capacity. Additionally, various hole patterns can be tailored to meet specific design intents, whether for aesthetic enhancements or functional requirements. A thorough understanding of these basic properties will significantly aid in choosing the right perforated metal panels that align with the project's goals and performance expectations.

When selecting perforated metal panels for your project, identifying your project requirements and objectives is critical to ensuring that you choose the right specifications. For instance, understanding the desired aesthetic can significantly influence your material selection. According to a recent industry report by the Metal Construction Association, approximately 60% of architects prioritize visual appeal in their projects. This figure underscores the importance of considering how perforation patterns can enhance the design and functionality of a space.

Another crucial aspect is the application of the panels. Different projects may require varying levels of durability, corrosion resistance, and strength. The National Institute of Standards and Technology notes that perforated metal has applications in various fields, from construction to automotive, with panels needing to withstand different environmental conditions. For example, in urban architecture, panels must often endure harsh weather, necessitating materials that are not only visually appealing but structurally sound and resistant to degradation over time.

Finally, it’s essential to evaluate environmental considerations, such as sustainability and energy efficiency. A study conducted by the Architectural Metal Association found that perforated metal can facilitate natural ventilation and daylighting, leading to reduced energy consumption in buildings by up to 25%. This makes it necessary to align your project objectives with environmental goals, ensuring that your choice of perforated panels not only meets functional requirements but also contributes positively to sustainable design practices.

| Project Requirement | Objective | Material Type | Perforation Pattern | Application |

|---|---|---|---|---|

| Sound Absorption | Reduce Noise Pollution | Aluminum | Round Holes | Acoustic Panels |

| Aesthetic Appeal | Enhance Visual Design | Stainless Steel | Square Holes | Architectural Facades |

| Ventilation | Improve Airflow | Mild Steel | Custom Patterns | Industrial Applications |

| Light Diffusion | Disperse Light | Brushed Aluminum | Offset Holes | Lighting Fixtures |

| Safety and Security | Prevent Unauthorized Access | Galvanized Steel | Diamond Pattern | Fencing |

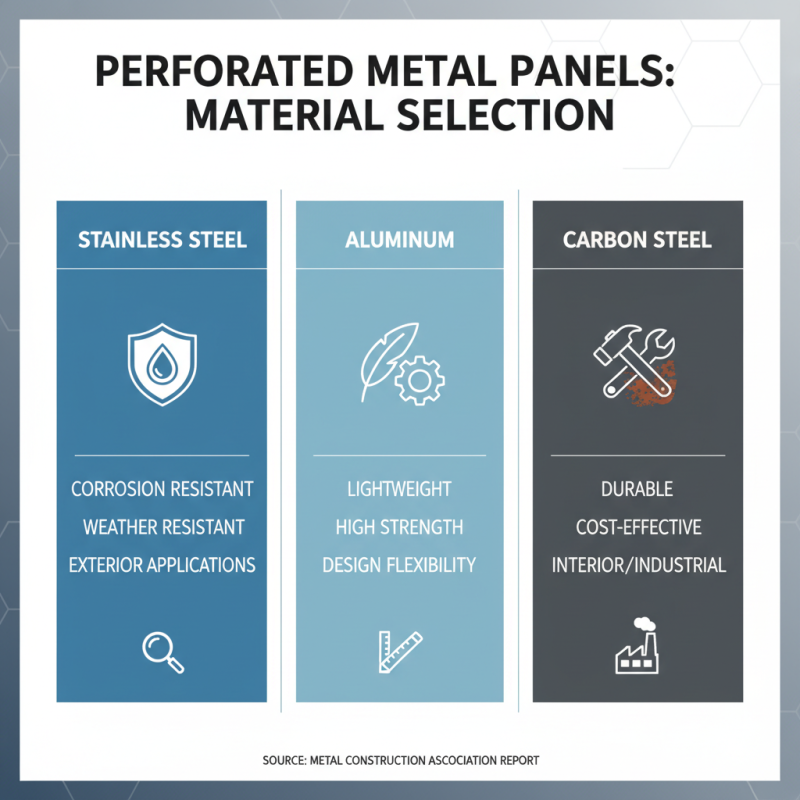

When selecting perforated metal panels for specific projects, the choice of material plays a crucial role in ensuring both durability and aesthetic appeal. Common materials include stainless steel, aluminum, and carbon steel, each offering distinct advantages. According to a report by the Metal Construction Association, stainless steel is regarded for its exceptional resistance to corrosion and weathering, making it suitable for exterior applications where longevity is paramount. Aluminum, on the other hand, is lightweight yet strong, providing excellent flexibility in design without compromising structural integrity.

In terms of aesthetics, perforated panels can significantly enhance the visual appeal of a project. A study by the American Institute of Steel Construction highlights that the design possibilities with perforated metal are nearly limitless, allowing for customized patterns and finishes that can complement any architectural style. The interplay of light and shadow created by the perforations can add depth and texture, making it a favored choice in modern design narratives. As industries increasingly prioritize sustainability, materials like aluminum are also found to have high recyclability rates, adding an environmentally friendly dimension to their aesthetic value. Ultimately, evaluating these material options based on durability and aesthetics is essential in selecting the right perforated metal panels for any project.

When selecting perforated metal panels for your project, understanding the various hole patterns and sizes is crucial for achieving both functionality and aesthetic appeal. Different hole patterns, such as round, square, or slotted, can significantly affect not only the appearance of the panel but also its performance in terms of light, sound, and airflow management. For instance, round holes are common for applications that require effective ventilation, while larger slots might be chosen for enhancing visibility or acoustics in architectural designs. The spacing between holes also plays a significant role, as denser arrangements can provide greater privacy or noise reduction compared to more open configurations.

Additionally, the size of the holes can have functional implications as well. Smaller holes tend to be more suitable for environments needing higher security or filtration, while larger holes may be ideal for decorative purposes or where airflow is a priority. It's essential to consider how these factors align with the intended use of the panels—whether it’s for building facades, interiors, or industrial applications. By carefully evaluating the different patterns and sizes, you can ensure that the selected perforated metal panels fulfill the specific demands of your project while enhancing its overall design.

When selecting the right perforated metal panels for your project, it’s crucial to consider the installation and maintenance factors that will contribute to the longevity of the materials. Proper installation not only ensures durability but also enhances the functional benefits of the panels. According to a report from the Metal Construction Association, employing best practices during installation can increase the lifespan of perforated metal up to 50%. Factors such as climate, exposure to elements, and structural support should be meticulously assessed to avoid issues like warping or rusting, which can significantly diminish performance over time.

In addition to installation, regular maintenance is essential to sustain the integrity of perforated panels. The National Association of Architectural Metal Manufacturers recommends a scheduled cleaning routine, especially in environments prone to debris accumulation or harsh weather conditions. Simple maintenance can prevent extensive damage; it is documented that untreated perforated metals can experience a corrosion rate increase of up to 100% over prolonged exposure without care. By proactively addressing installation and maintenance factors, you can ensure that your perforated metal panels stand the test of time while effectively meeting your project needs.