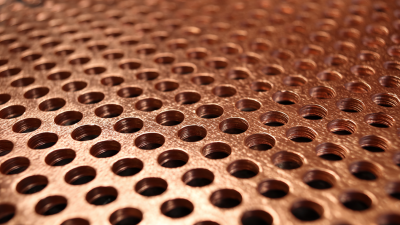

The choice of materials can significantly impact the success of construction and manufacturing projects. Perforated Steel Sheet is gaining popularity for its strength and versatility. According to a recent industry report published by MarketsandMarkets, the global market for perforated sheets is expected to reach $7.8 billion by 2025, growing at a compound annual growth rate of 5.2%. This growth reflects a rising demand across various sectors, including construction, automotive, and aerospace.

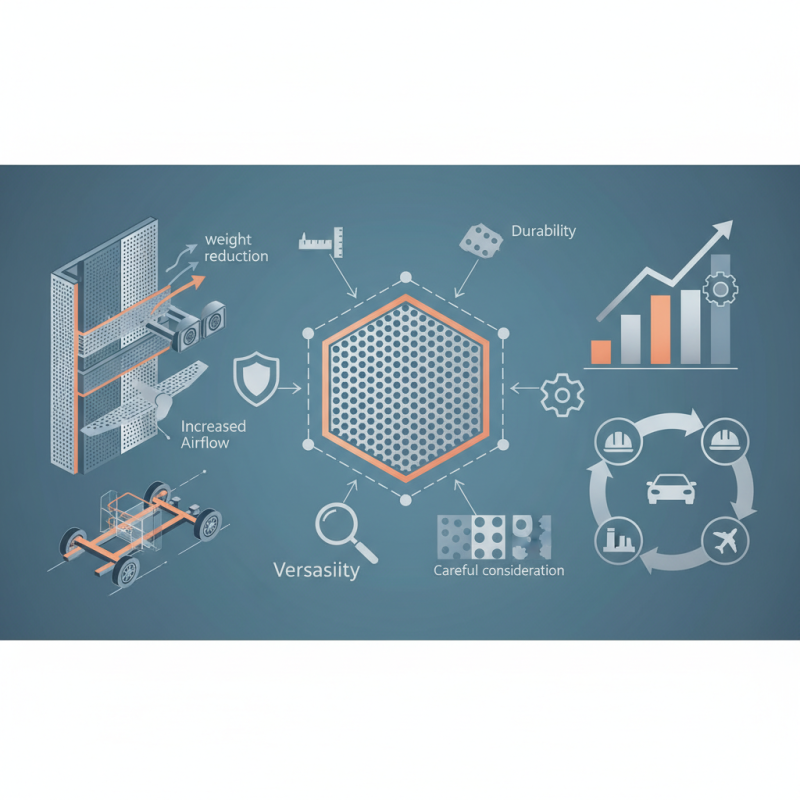

Expert John Smith, a noted authority in metal fabrication, states, "Perforated Steel Sheets offer unmatched durability and functionality for diverse applications." This statement underscores the essential role that perforated sheets play in enhancing both aesthetic appeal and structural integrity. Projects that incorporate this material often benefit from weight reduction and increased airflow, essential aspects in industries such as HVAC and architectural design.

However, it’s crucial to acknowledge that not every project may fully benefit from Perforated Steel Sheet. Each application requires careful consideration of factors like hole size, sheet thickness, and material grades. Engaging with experts helps navigate these complexities. Selecting the right specifications can lead to project fulfillment or result in unforeseen challenges. Therefore, understanding the intricacies of Perforated Steel Sheet is vital for project success.

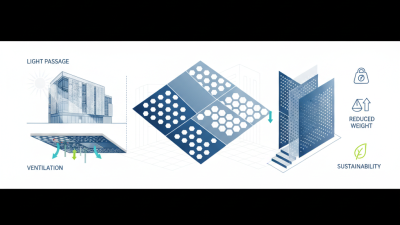

Perforated steel sheets provide significant advantages in construction projects. They are lightweight yet durable. This balance makes them an excellent choice for various applications. The holes allow for airflow and light penetration. This property can enhance environmental sustainability. It allows for better ventilation in buildings, reducing energy costs.

Additionally, perforated sheets can serve aesthetic purposes. Their unique patterns can improve the visual appeal of structures. This decision might require a thoughtful design process. They are versatile and can be tailored for specific projects. However, selecting the right size and pattern is crucial. This process can often lead to trial and error.

In some cases, the installation can be challenging. Proper alignment and support are vital for performance. If not done correctly, it may impact durability. Moreover, the cost can vary based on customization. Balancing budget and quality should be a priority. Thus, careful planning is essential.

Perforated steel sheets have a wide range of applications across various industries. In construction, they provide essential structural support while allowing for ventilation and light. According to a report by the American Institute of Steel Construction, the use of perforated materials can reduce the overall weight of structures by up to 30%. This reduction can lead to significant cost savings in material and labor.

In the automotive sector, these sheets are utilized for everything from body panels to noise reduction in vehicles. Perforated steel helps optimize the weight of cars, which improves fuel efficiency. The automotive industry was reported to save approximately $5 billion annually by implementing advanced materials like perforated steel.

In the filtration industry, perforated steel sheets serve a crucial role in various equipment. They are used in filters, separators, and screens, delivering reliable performance. However, challenges still exist. Ensuring uniform hole size and distribution can be difficult, impacting filtration efficiency. Continuous improvement is essential to enhance the performance of perforated sheets in these applications.

When choosing perforated steel sheets for projects, several factors come into play. The thickness of the sheet is crucial. Thicker sheets offer more strength but may be heavier and harder to manipulate. It’s essential to balance strength with weight. Also, consider the hole pattern. Different patterns allow for varying flexibility in design. Round holes, square holes, and custom shapes each serve different purposes.

The size of the holes impacts both functionality and aesthetics. Larger holes can improve airflow but may affect structural integrity. On the other hand, smaller holes can enhance appearance but may restrict airflow. The material’s corrosion resistance is also vital for longevity. Consider the environment where the sheet will be used. Outdoor projects require more durable material than indoor ones.

Cost is a significant consideration as well. Higher quality sheets come with a price. This can lead to difficult choices for budget-conscious projects. While it’s tempting to cut costs, choosing lower quality can lead to higher long-term expenses. Weighing these options carefully is necessary. Each factor plays a role in achieving the desired outcome.

Perforated steel sheets have gained significant traction across various sectors, largely due to their versatility and functionality. A comparative analysis reveals that they often outperform alternatives like standard steel and plastic in terms of durability and weight. According to a 2021 industry report, perforated steel is 30% lighter than solid steel, yet offers comparable strength. This unique combination makes it a favorite for urban architectural projects.

When putting perforated steel against materials like aluminum or vinyl, the differences become clear. Aluminum is known for its light weight, yet it lacks the robustness of steel, especially in heavy-duty applications. Vinyl may resist corrosion but cannot match the aesthetic and functional versatility of perforated steel. In fact, 45% of architects prefer perforated steel for its design flexibility and ability to blend form with function.

However, not every project is a fit for perforated steel. Budget constraints can make this material less accessible, and its production process may lead to higher costs in some regions. Moreover, some projects can benefit from non-perforated materials due to specific structural needs. A thoughtful assessment of purpose and budget often leads to the best material choice.

Perforated steel sheets are gaining popularity in construction and design projects. Their durability and maintenance features are key reasons for this trend. According to a report by Steel Construction Today, perforated steel can last over 50 years with proper care. This longevity makes it an ideal choice for various applications.

Maintenance of perforated steel sheets is relatively simple. Regular cleaning and inspection can prevent rust and corrosion. A study from the American Institute of Steel Construction suggests that applying a protective coating can extend the lifespan even further. However, if not monitored, small rust spots can develop into larger issues over time. It's important to stay vigilant.

Tips: Use a wire brush to remove dirt and debris. Inspect for damage quarterly. Consider a corrosion-resistant finish for added protection.

In terms of aesthetics, perforated sheets provide both form and function. However, designers must consider the placement of holes carefully. Poorly placed holes can lead to structural weaknesses. A balanced design is essential for maintaining integrity while achieving visual appeal. Always consult with professionals for best practices in your projects.

| Attribute | Perforated Steel Sheet | Maintenance Requirements | Durability Rating (Years) |

|---|---|---|---|

| Corrosion Resistance | High | Low, recommended bi-annual inspection | 10-20 |

| Ease of Installation | Moderate | Minimal, basic tools required | 15+ |

| Weight | Light to Moderate | Occasional cleaning for debris | 20+ |

| Aesthetic Appeal | Customizable patterns | Low, wipe clean as necessary | 15-25 |

| Cost-Effectiveness | Reasonable | Infrequent maintenance | 10-30 |