Choosing the best antiskid perforated mesh is crucial for ensuring safety in various environments. This material serves as a reliable solution across many industries. It can prevent slips and falls, making it essential for workplaces, homes, and public areas.

When selecting antiskid perforated mesh, consider its material and texture. Different surfaces provide varying levels of grip. Ensure the mesh fits the intended location well. A poorly chosen mesh might lead to unsafe conditions. Look for options that match your safety requirements effectively.

Visual aspects also matter. The color and design can impact visibility. Bright or contrasting colors enhance awareness of the surface. Evaluate the durability of the antiskid perforated mesh, as wear and tear can diminish its effectiveness over time. Regular inspections help maintain safety standards. Remember, a safe choice today can lead to fewer accidents tomorrow.

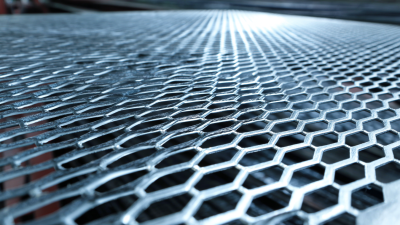

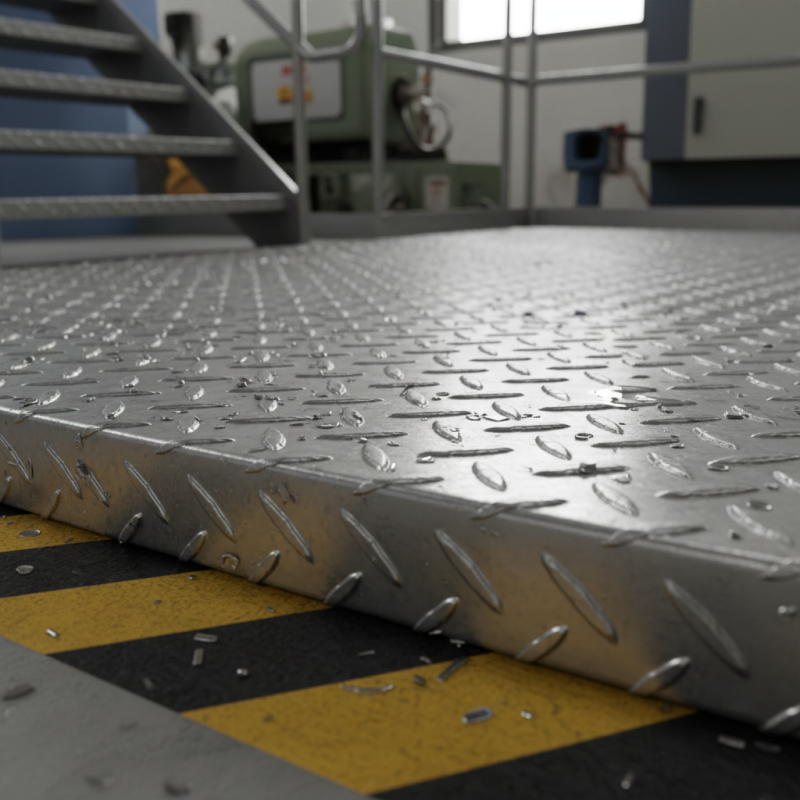

Antiskid perforated mesh plays a crucial role in safety across various environments. It provides traction and prevents slips, making it an essential material for flooring, ramps, and surfaces where people walk or work.

The small holes in the mesh allow for drainage and prevent water accumulation. This feature is vital in wet conditions, reducing the risk of accidents.

When choosing the right mesh, consider the specific environment. Wet areas like pools require a different texture compared to industrial settings. The material's durability is equally important. It should withstand high foot traffic or heavy machinery without degrading. However, not all options are created equal; some may wear out quickly or become slippery when wet.

Aesthetic considerations cannot be overlooked either. While functionality is key, the mesh's appearance should complement the surroundings. Color and design matter, particularly in public spaces. Striking a balance between form and function is often challenging. Ultimately, carefully assessing the needs of your environment will lead to better safety outcomes.

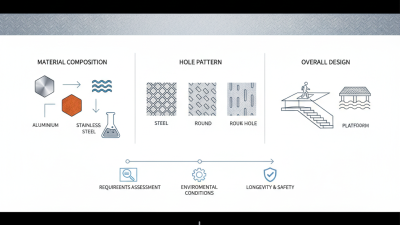

When choosing antiskid perforated mesh, several important factors come into play. It's crucial to consider the material's durability. Materials should resist wear and tear. You want mesh that can withstand various weather conditions. A robust mesh also enhances safety in high-traffic areas.

Another aspect is the perforation size and pattern. Smaller holes provide greater grip but may trap debris. This could lead to maintenance issues over time. Larger holes allow for better drainage but might not offer the same traction. Finding a balance is essential for safety and usability.

Additionally, think about the application. Will it be used indoors or outdoors? The environment greatly impacts your choice. For wet areas, consider non-slip properties. Sometimes, the most suitable option isn't the first one you find. Take time to reflect on your specific needs before making a purchase.

| Factor | Description | Importance Level (1-5) |

|---|---|---|

| Material | The type of material affects durability and slip resistance. | 5 |

| Hole Size | Larger holes provide better drainage but may reduce traction. | 4 |

| Thickness | Thicker mesh generally offers more safety and strength. | 5 |

| Surface Texture | A rough texture enhances grip and reduces slippage. | 5 |

| Environmental Resistance | Ability to withstand various weather conditions and chemicals. | 4 |

| Load Capacity | Ensure the mesh can support the expected weight. | 5 |

| Ease of Installation | Consider if the mesh can be easily cut and installed. | 3 |

| Cost | Balance between cost and quality for best value. | 4 |

When selecting antiskid perforated mesh, understanding the different types is crucial. Common materials include metal, plastic, and rubber. Each type offers unique benefits. Metal mesh provides high durability and is resistant to extreme conditions. It boasts a slip resistance of up to 80 percent, as noted by industry reports. This makes it a go-to choice for industrial settings where safety is paramount.

Plastic mesh, on the other hand, is lightweight and less expensive. It’s ideal for low-traffic areas. However, its slip resistance may not match that of metal. Some reports indicate a slip resistance rate of approximately 60 percent. This could raise concerns in wet conditions. Rubber mesh offers excellent grip and flexibility. It's often used in commercial spaces. But, its longevity can vary greatly. Regular maintenance is needed to ensure safety standards.

Choosing the right mesh isn't just about cost or appearance. It’s essential to consider where and how the mesh will be used. Reflecting on past incidents in various industries reminds us of the importance of proper material selection. A mismatch can lead to unsafe environments, undermining safety efforts.

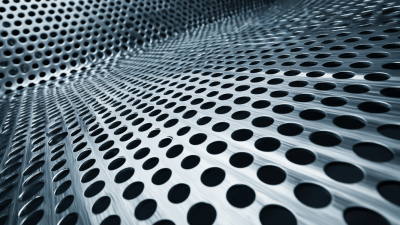

When selecting antiskid perforated mesh for safety, evaluating its slip resistance is crucial. Various testing standards assess how well the material performs under different conditions. These tests often simulate wet or oily surfaces. The results determine how safe the mesh is in real-world scenarios. Understanding the coefficient of friction is important. A higher value indicates better slip resistance, which can save lives.

Durability testing is equally important. Materials need to withstand wear and tear over time. Exposure to weather elements can affect their integrity. Regular assessment is necessary to ensure continued safety performance. Some products may seem strong, but they can deteriorate quickly in harsh conditions. Users should look for signs of wear and consider replacing the mesh when needed.

Sometimes, data from tests can paint a misleading picture. A product may pass initial tests but fail in practical applications. Real-life usage can reveal flaws that standards do not capture. Users should consult reviews and feedback from real-world applications. This information can provide insights that standardized tests might overlook.

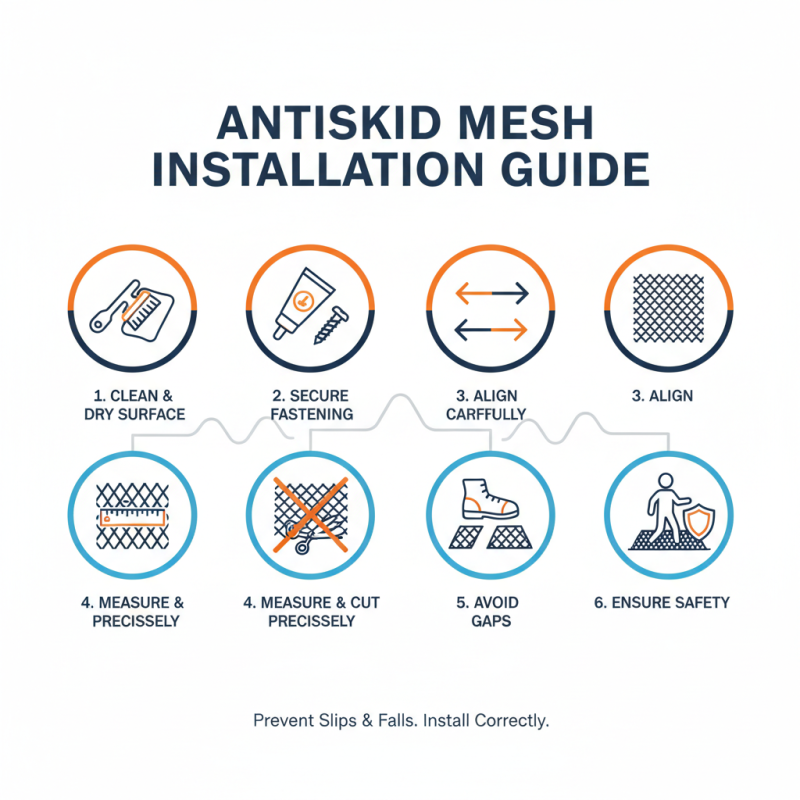

When installing antiskid perforated mesh, proper preparation is key. Ensure the surface is clean and dry to establish a secure bond. Use appropriate adhesives or fastening methods to secure the mesh firmly. Pay attention to the alignment, as any misplacement can compromise safety. Measure carefully before cutting the mesh to fit the area perfectly. Remember, even slight gaps can lead to slips and falls.

Maintenance is equally crucial for maximizing antiskid safety. Regular inspections will help identify wear or damage. Check for loose edges or deterioration in the mesh. If you notice any issues, replacing sections promptly can prevent accidents. Keep the mesh free of debris, such as dirt or leaves that may hinder its performance. Cleaning it with mild detergents will maintain its effectiveness.

Sometimes, people overlook simple measures, thinking they are sufficient. Revisiting installation spots is important. Minor adjustments today can save major troubles tomorrow. Always reflect on past installations to improve future safety measures. Consider feedback from others to enhance your approach. It’s a continuous learning process that should never be underestimated.