In the evolving landscape of construction and design, the selection of materials is paramount, especially when it comes to safety and functionality. Antiskid Perforated Mesh has emerged as a critical component for various projects, providing enhanced traction and durability for a range of applications. Renowned expert in industrial materials, Dr. Emily Carter, emphasizes the importance of making educated choices in this domain, stating, "The right Antiskid Perforated Mesh can significantly improve safety and performance, ensuring that projects meet both functional and aesthetic demands."

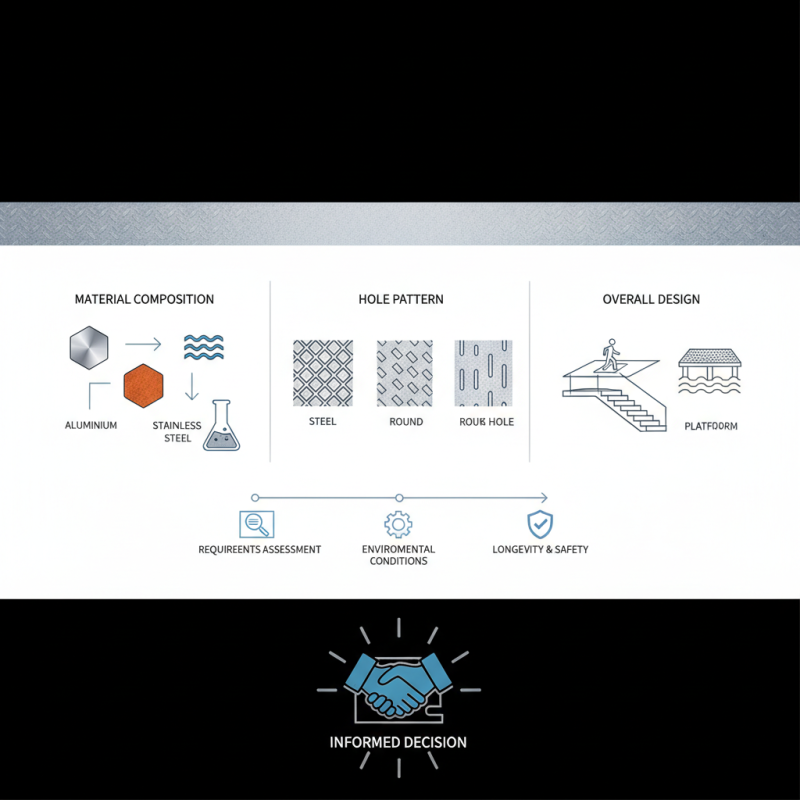

When embarking on the journey to choose the best Antiskid Perforated Mesh for your project, it becomes essential to consider several factors, such as material composition, hole pattern, and overall design. Understanding the specific requirements of your application and the environmental conditions it must withstand is crucial. This selection process not only influences the effectiveness of the mesh but also impacts the longevity of your project, ensuring that it can withstand the test of time.

As we delve deeper into the nuances of Antiskid Perforated Mesh, it is vital to explore various types and their specific benefits. This guide aims to provide valuable insights and practical advice, empowering you to make informed decisions that enhance safety and functionality in your projects.

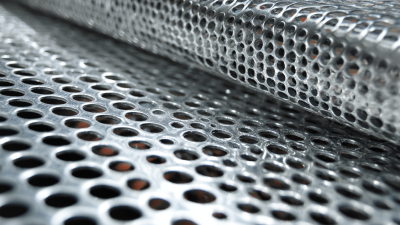

Antiskid perforated mesh is a versatile material commonly used in various applications to enhance safety and functionality. This type of mesh is designed with perforations that not only reduce weight but also improve traction, making it ideal for flooring in industrial settings, walkways, and even sports facilities. The unique structure of antiskid perforated mesh allows for drainage, minimizing the risk of slip hazards in wet or muddy conditions. Its durability and resistance to wear make it an excellent choice for environments where safety is a priority.

In addition to its practical applications, antiskid perforated mesh is increasingly being utilized in architectural designs, offering aesthetic appeal alongside performance. The mesh can be customized in terms of patterns, sizes, and materials, providing architects and designers with flexibility to incorporate it into their projects. Whether used in exterior cladding for enhanced grip and safety or in interior designs to create visually striking features, antiskid perforated mesh bridges the gap between functionality and innovative design. Understanding these characteristics and applications can significantly aid in selecting the right type of mesh for specific project requirements.

When selecting the best antiskid perforated mesh for your project, several critical factors should be taken into consideration. First, evaluate the intended use and environment of the mesh. Different applications, whether for flooring, walkways, or industrial use, may require varying levels of durability and slip resistance. For example, a mesh used in wet or oily environments must offer superior traction to prevent accidents, while one used in dry areas may focus more on ventilation and load-bearing capacity.

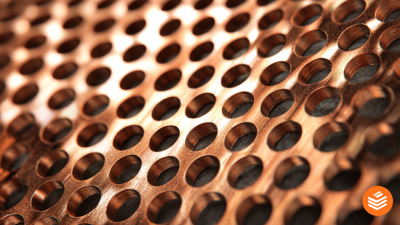

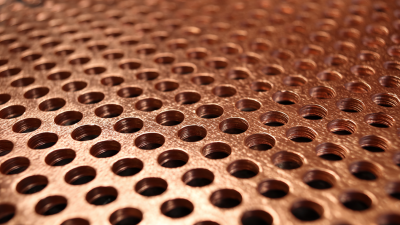

Another important factor is the material composition of the perforated mesh. Common materials include steel, aluminum, and various polymers, each exhibiting distinct properties in terms of strength, weight, and resistance to corrosion. Assessing the environmental conditions, such as exposure to moisture, chemicals, or temperature fluctuations, can guide you in choosing a material that will withstand the test of time. Additionally, the mesh's perforation pattern and size should align with your specific requirements for airflow, drainage, and aesthetic appeal, ensuring it integrates seamlessly into the overall design of your project.

When it comes to selecting the best antiskid perforated mesh for your project, the material choices are crucial for ensuring safety and durability. Common materials used in antiskid perforated mesh include stainless steel, aluminum, and fiberglass. Stainless steel is favored for its strength and corrosion resistance, making it ideal for outdoor applications where weather exposure is a concern. Aluminum, being lightweight and easy to fabricate, is a popular choice for various indoor applications, providing an excellent balance of strength and ease of installation. Fiberglass, on the other hand, offers a non-corrosive option that is particularly suitable for environments that may involve chemicals or other harsh substances.

Tips: Consider the environment where the mesh will be installed. For high-moisture areas, stainless steel may be the best option to prevent rusting. In contrast, aluminum can be more suitable for quick, temporary installations.

In addition to material, the hole size and pattern in the perforated mesh should be assessed based on the specific application requirements. Smaller holes can provide better traction and are excellent for foot traffic areas, while larger holes may enhance drainage in outdoor settings. It's essential to also evaluate the thickness of the mesh, as this impacts both its weight-bearing capacity and durability.

Tips: Assess the specific needs of your project, including traffic levels and environmental exposure, to determine the optimal hole size and mesh thickness for your application.

This chart illustrates the different types of materials commonly used in antiskid perforated mesh projects. Each material is represented as a percentage of its usage relative to others in various applications.

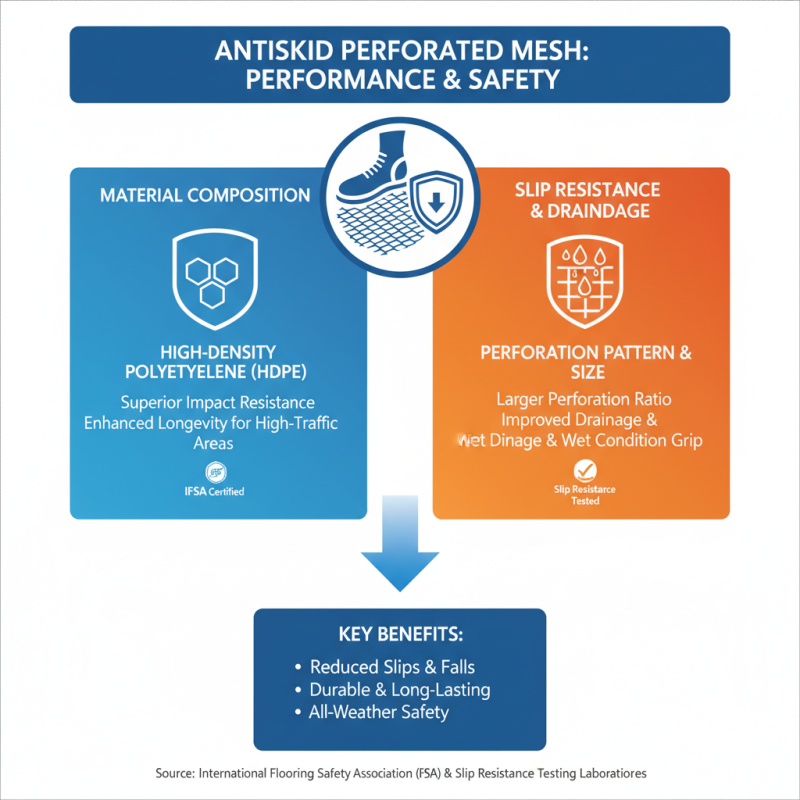

When evaluating the performance and safety features of antiskid perforated mesh, it is essential to consider several critical factors. First and foremost, the material composition plays a significant role in ensuring durability and functionality. According to the International Flooring Safety Association (IFSA), meshes made from high-density polyethylene (HDPE) demonstrate superior impact resistance and longevity, making them ideal for high-traffic areas. Furthermore, the pattern and perforation size can significantly affect the slip resistance. A study by the Slip Resistance Testing Laboratories illustrates that surfaces with a larger perforation ratio offer better drainage, reducing water accumulation and enhancing grip under wet conditions.

To enhance safety in your project, it's advisable to assess the mesh's tactile surface features. Textured surfaces can increase friction, which is crucial during wet or oily conditions. Research shows that a raised surface can improve the coefficient of friction significantly, thereby lowering the risk of slips and falls. When choosing your antiskid mesh, look for products that have been tested in real-world conditions, as these provide a more accurate picture of their performance.

Tips: Ensure that any antiskid mesh meets the required safety standards set by your local regulations. Look for certifications from recognized organizations which can help in making an informed choice. Additionally, consider seasonal factors—some meshes perform better under specific weather conditions, which can influence their safety features for your project.

When installing antiskid perforated mesh, it's crucial to first assess the project's specific requirements, including the environment and intended use. Ensure that the mesh material fits the surface where it will be applied, whether that’s flooring, walkways, or staircases. The surface should be clean and dry to promote optimal adhesion. Using appropriate adhesives or mechanical fastening methods is key to enhancing durability and preventing accidental slips.

During installation, consider the orientation of the mesh. Proper alignment can significantly influence the effectiveness of the antiskid features. For outdoor projects, ensure that the mesh is adequately secured to withstand weather conditions like rain or snow. Additionally, factor in the thickness and dimensions of the perforated mesh to comply with safety regulations, as these elements will influence the overall stability and effectiveness of the installation. Always follow safety guidelines throughout the installation process to protect workers and end-users.

| Project Type | Material | Grip Level | Installation Difficulty | Cost Range (per sq ft) |

|---|---|---|---|---|

| Decking | Aluminum | High | Moderate | $5 - $10 |

| Flooring | Steel | Medium | Easy | $3 - $8 |

| Ramps | Fiberglass | High | Moderate | $6 - $12 |

| Walkways | Plastic Composite | Medium | Easy | $4 - $9 |

| Playgrounds | Rubber | Very High | Difficult | $7 - $15 |