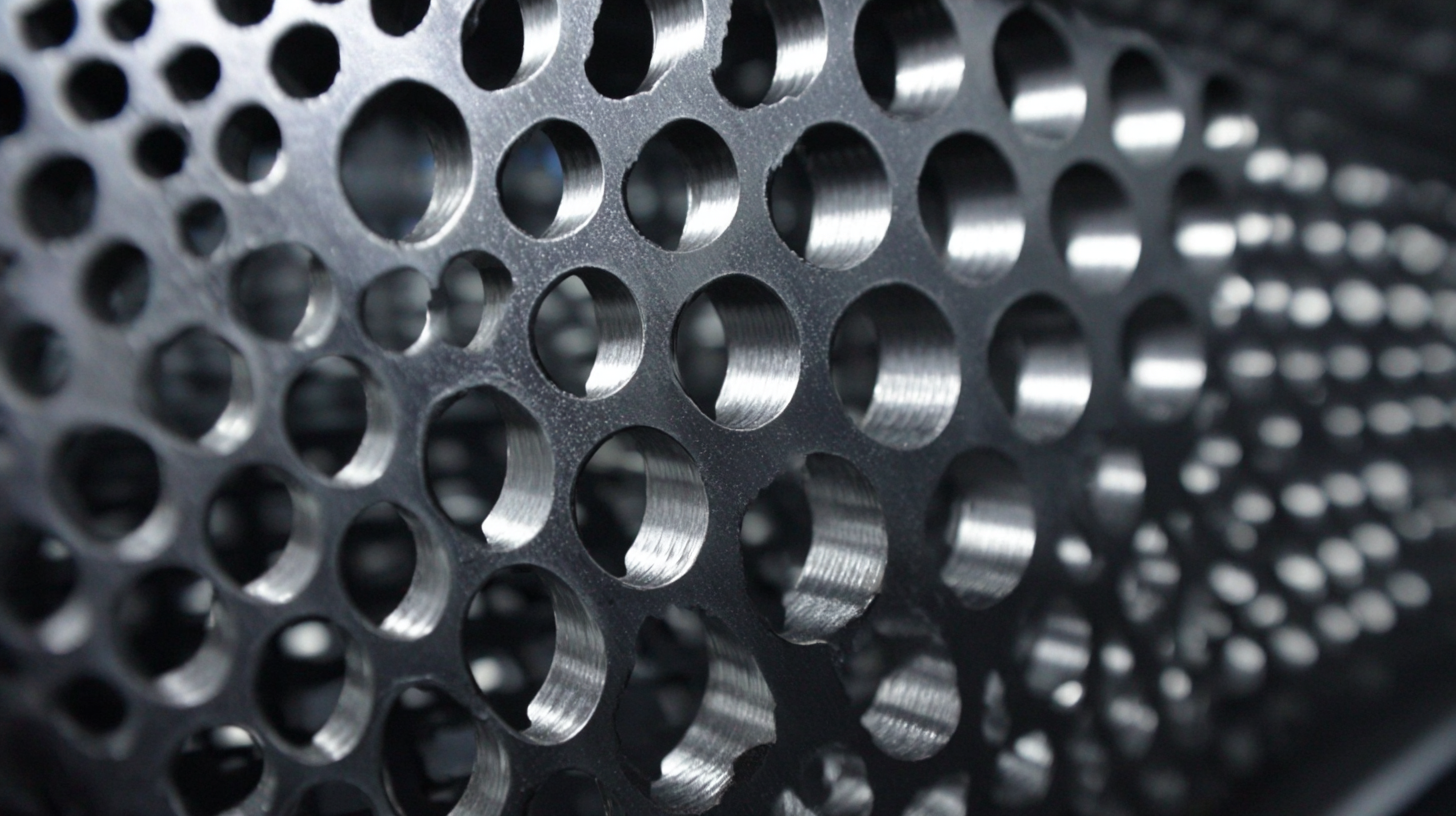

In today's competitive manufacturing landscape, the significance of high-quality Punched Metal Sheets cannot be overstated. According to a report by Grand View Research, the global metal stamping market is projected to reach USD 253.2 billion by 2025, reflecting a compound annual growth rate (CAGR) of 4.7%. As industries increasingly demand precision-engineered components, the advantages of superior after-sales service and cost-effective repair solutions become paramount. Manufacturers that focus on efficient service channels and maintenance strategies not only enhance customer satisfaction but also reduce long-term operational costs. By prioritizing these aspects, China's Premier Factory not only delivers exceptional Punched Metal Sheets but positions itself as a leader in the global market, ensuring that clients receive ongoing support and value long after the initial purchase.

In the ever-evolving landscape of China's manufacturing industry, export and import certifications serve as crucial pillars ensuring quality and compliance. The International Organization for Standardization (ISO) reports that certified manufacturers experience a 20% increase in international orders due to the assurance of quality they provide. For Chinese manufacturers of punched metal sheets, having the right certifications not only enhances their reputation but also opens doors to global markets, allowing them to compete effectively on the international stage.

Tip: For manufacturers looking to expand their reach, investing in obtaining relevant certifications such as ISO 9001 and CE marking is essential. Not only do these certifications build trust with customers, but they also streamline processes and enhance product quality.

Moreover, the significance of these certifications extends beyond just compliance. According to a study by the China Association of Metal Processing Industry, 65% of manufacturers that prioritize certification processes reported improved operational efficiencies. As organizations strive for excellence, well-defined certifications can lead to better supply chain management and heightened customer satisfaction.

Tip: It's important for manufacturers to stay updated on changes in certification requirements and standards to remain competitive. Regular training and audits can assist in maintaining compliance and driving growth.

In the competitive landscape of the punched metal sheet industry, obtaining industry-specific certifications is paramount for manufacturers seeking to establish credibility and market presence. Certifications such as ISO 9001, which focuses on quality management systems, are essential as they help companies demonstrate their commitment to quality assurance. According to a report by Industry Research, about 75% of customers are more likely to choose manufacturers with recognized certifications when sourcing parts, underscoring the significance of certification in building trust within the supply chain.

Furthermore, the compliance with standards set by organizations like the American National Standards Institute (ANSI) and the International Organization for Standardization (ISO) not only enhances product quality but also improves operational efficiency. For instance, adhering to these standards often leads to a 20% reduction in production costs due to streamlined processes and waste reduction, as highlighted in recent industry studies. As a result, manufacturers that prioritize these certifications can not only provide exceptional punched metal sheets but also establish themselves as leaders in the global market.

In an increasingly competitive global market, China's premier factory stands out by ensuring that its punched metal sheets meet rigorous quality standards. The commitment to quality is foundational, encompassing every step of the production process. With state-of-the-art equipment and skilled technicians, the factory implements strict quality control measures, ensuring that each product not only meets but often exceeds international specifications. This dedication to excellence has cemented its reputation in various industries, from automotive to construction.

In an increasingly competitive global market, China's premier factory stands out by ensuring that its punched metal sheets meet rigorous quality standards. The commitment to quality is foundational, encompassing every step of the production process. With state-of-the-art equipment and skilled technicians, the factory implements strict quality control measures, ensuring that each product not only meets but often exceeds international specifications. This dedication to excellence has cemented its reputation in various industries, from automotive to construction.

Tips for Ensuring Quality Standards: One effective tip is to integrate automated inspection systems in the production line. These systems can quickly identify defects that manual inspections might miss. Furthermore, maintaining comprehensive documentation throughout the production process can facilitate compliance with global standards and streamline quality audits.

Another key recommendation is to invest in staff training. Regular training sessions on quality assurance best practices empower employees to take ownership of their work, fostering a culture of quality throughout the organization. By nurturing a knowledgeable workforce and leveraging technology, factories can consistently deliver exceptional products that satisfy the evolving demands of the global market.

In the realm of international trade, navigating regulatory compliance for metal products is a paramount concern for manufacturers, particularly in a booming market like China. As per a 2023 industry report by the International Trade Administration, China's metal exports reached approximately $130 billion, reflecting a robust demand worldwide. However, with such opportunities come stringent regulations that must be adhered to. These include compliance with international standards such as ISO 9001 for quality management and ISO 14001 for environmental management, which ensure that manufacturers not only provide high-quality metal sheets but also operate sustainably.

Moreover, the complexities of trade agreements and tariffs further complicate the landscape. According to a study published by the World Bank, compliance failures can lead to penalties amounting to 20% of the transaction value, significantly impacting profit margins for exporters. Understanding and aligning with both domestic regulations and the importing countries’ requirements is crucial. Staying informed about the evolving regulatory frameworks can ultimately enhance competitiveness. Companies in China's metal manufacturing sectors must prioritize compliance strategies, invest in continuous employee training, and engage with legal experts to successfully navigate these challenges and leverage their production capabilities on a global scale.

When collaborating with Chinese manufacturers, particularly in the production of punched metal sheets, establishing clear communication channels is paramount. A well-defined scope of work allows both parties to align their expectations, reducing misunderstandings that could delay production schedules. Regular updates and progress reports will ensure that any potential issues are addressed promptly, fostering a more efficient workflow. Furthermore, leveraging digital tools like shared project management platforms can help streamline collaboration, making it easier to track progress and maintain accountability.

Additionally, understanding cultural nuances can significantly enhance partnership success. Building relationships based on trust is crucial when working with Chinese suppliers. Taking the time to engage in face-to-face meetings—whether through visits to the factory or video calls—can create a more personal connection and encourage mutual respect. Moreover, demonstrating an appreciation for Chinese business etiquette, such as the importance of hierarchy and consensus, can lead to smoother negotiations and foster a long-term partnership that benefits both parties in the global supply chain.