In today’s competitive industrial landscape, selecting the right materials is crucial for optimizing performance and durability. Perforated Plate Steel has emerged as a vital component across various sectors, offering a blend of aesthetic appeal and functional robustness. According to a recent industry report by Global Market Insights, the perforated metal market is set to surpass USD 3 billion by 2026, with the demand for perforated plate steel rising significantly in applications such as architectural design, filtration, and sound control. With China being a leading manufacturer, exporting to markets worldwide, understanding the nuances of choosing the best perforated plate steel is essential. This ultimate checklist will guide you through the critical factors to consider, ensuring that your selection aligns with both your operational needs and industry standards.

When selecting the best perforated plate steel for your specific needs, understanding the key metrics is crucial. Factors such as the thickness of the plate, hole size and pattern, and the mechanical properties of the steel significantly impact performance. Recent studies highlight that the stiffness (K) and slenderness factor (λ) of perforated plates influence their effectiveness in structural applications. With advancements in modeling, the ABAQUS simulation software can analyze elastic-inelastic-plastic buckling (EIP) modes, providing a deeper understanding of how perforated plates respond under various load conditions.

Moreover, the material properties of steel vary under cyclic and monotonic loads, which directly affects the durability and resilience of perforated structures. According to industry reports, steel's mechanical properties may be optimized for specific applications by adjusting hole configurations and plate dimensions to minimize weight while ensuring structural integrity. For instance, using finite element analysis has proven effective in predicting the behavior of plates in real-world scenarios, enabling engineers to make informed decisions on the design and selection of perforated plate steel tailored to their engineering requirements.

When selecting perforated plate steel, the choice of material grade is crucial, as it significantly impacts the performance and longevity of the finished product. According to the World Steel Association, over 1.8 billion tonnes of steel are produced annually, with varying grades tailored for different applications. For instance, structural steels like ASTM A36 provide sufficient strength for general fabrication but may not be ideal for corrosive environments. In contrast, higher-grade steels such as ASTM A572 offer enhanced strength and better fatigue resistance, making them suitable for demanding applications.

The impact of steel grades goes beyond just mechanical properties; it also influences factors such as corrosion resistance and weldability. A recent report by the Steel Construction Institute suggests that using galvanized mild steel can improve durability in outdoor settings, extending the service life of perforated plates by up to 50%. Furthermore, selecting the right grade can reduce maintenance costs, as high-quality materials often require fewer repairs over time. Understanding these differences is essential for manufacturers and engineers when sourcing perforated plate steel to match their specific needs.

| Steel Grade | Tensile Strength (MPa) | Yield Strength (MPa) | Thickness Range (mm) | Common Applications |

|---|---|---|---|---|

| A36 | 400-550 | 250-400 | 6 - 50 | Structural applications, beams, columns |

| SS304 | 520-720 | 200-550 | 0.3 - 6 | Corrosion-resistant applications, kitchen equipment |

| Mild Steel | 370-540 | 210-350 | 2 - 25 | General fabrication, automotive parts |

| High Strength Low Alloy (HSLA) | 550-800 | 340-550 | 5 - 20 | Heavy construction, bridges |

| Galvanized Steel | 350-450 | 210-300 | 1 - 10 | Outdoor applications, fencing, roofing |

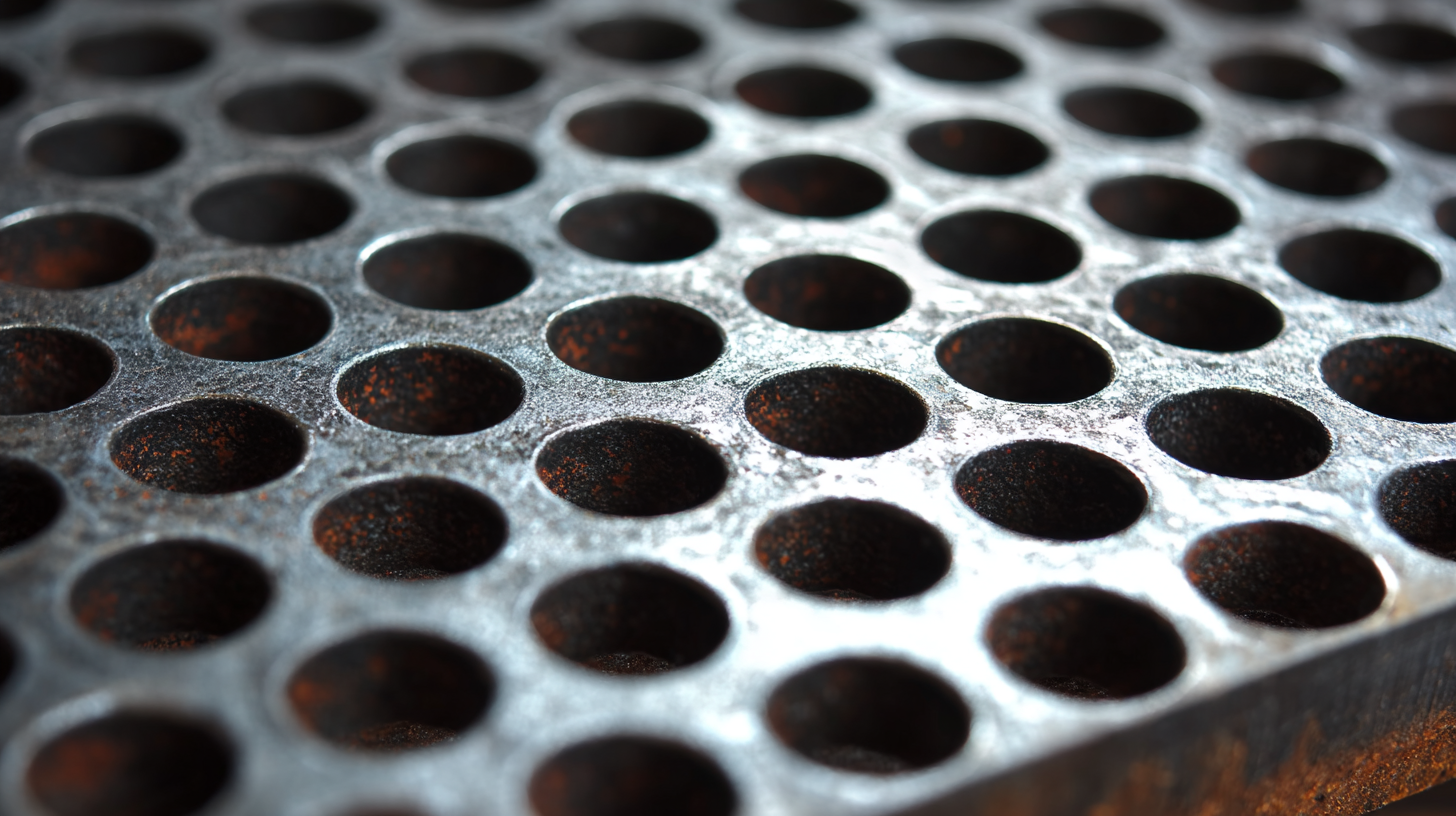

When it comes to selecting perforated plate steel, the size of the holes and their arrangement can significantly impact the material's performance. Different applications require specific hole sizes to optimize airflow, drainage, or weight reduction. For instance, a larger hole diameter might be ideal for ventilation systems where maximum air exchange is crucial, whereas smaller holes are preferred for applications where particle retention is necessary, like in filtering or sieving processes. Understanding the correlation between hole size and functionality can enhance the efficiency of your project.

Moreover, the perforation patterns—whether they are staggered, uniform, or custom designs—also play a vital role in the distribution of strength and flexibility. Staggered patterns can improve load-bearing characteristics, while uniform patterns may provide consistent aesthetics and performance. For instance, if your application requires a combination of lightness and structural integrity, choosing the right pattern along with the appropriately sized holes can lead to superior results. Thus, paying close attention to these details will ensure that the perforated plate steel you choose meets your specific operational needs effectively.

This chart illustrates the functionality ratings of various perforated plate steel options based on hole size and pattern, highlighting how different designs can impact their effectiveness for specific applications.

When selecting perforated plate steel for your project, understanding the load-bearing capacity is paramount. The specific strength requirements largely depend on the application, be it architectural, industrial, or decorative. According to the Steel Shapes Design Manual, a typical perforated plate can support a load ranging from 2,000 to 4,000 pounds per square foot, depending on factors such as plate thickness and hole size. This detail is crucial when designing structures that must endure substantial weight or dynamic loads.

When selecting perforated plate steel for your project, understanding the load-bearing capacity is paramount. The specific strength requirements largely depend on the application, be it architectural, industrial, or decorative. According to the Steel Shapes Design Manual, a typical perforated plate can support a load ranging from 2,000 to 4,000 pounds per square foot, depending on factors such as plate thickness and hole size. This detail is crucial when designing structures that must endure substantial weight or dynamic loads.

It is also essential to consider the distribution of loads across the perforated plate. The American Institute of Steel Construction (AISC) suggests that when designing for uniform loads, engineers should account for the moment of inertia, which can be influenced by the arrangement and size of the perforations. For instance, a plate with larger, closely spaced holes may have a lower weight capacity compared to a plate with smaller, widely spaced holes. Thus, analyzing the specific load-bearing requirements of your project against the structural properties of the chosen perforated steel can help ensure safety and long-term performance.

When selecting perforated plate steel, finishes and coatings play a crucial role in enhancing both durability and aesthetics. According to the American Galvanizers Association, hot-dip galvanizing increases the lifespan of steel by providing a protective zinc coating that can last up to 50 years, depending on environmental conditions. This long-lasting protection is essential for applications in harsh environments, where exposure to moisture and chemicals can lead to rapid corrosion.

Moreover, coatings such as powder coating not only offer aesthetic versatility but also improve resistance to UV rays and physical wear. A report from Research and Markets highlighted that the global metal coatings market is expected to grow at a CAGR of 4.5% through 2027, driven by the increasing demand for durable and visually appealing products. By choosing perforated plates with appropriate finishes and coatings, industries can achieve not only enhanced functionality but also an impressive visual appeal that aligns with modern architectural standards.