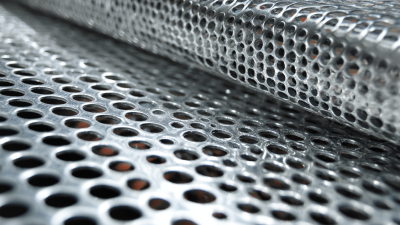

The increasing popularity of Perforated Corrugated Metal Panels in architectural design and construction has brought to light various challenges associated with their use. As reported by the Metal Building Manufacturers Association, the market for metal panels is projected to grow substantially, with a compound annual growth rate of 5.2% from 2021 to 2028. Despite their aesthetic appeal and functionality, these panels present unique issues, such as structural integrity, installation difficulties, and long-term maintenance concerns. Furthermore, a study by the American Institute of Steel Construction highlighted the importance of material selection and perforation patterns, which can significantly influence performance and durability. Addressing these challenges is crucial for architects, builders, and engineers aiming to leverage the advantages of Perforated Corrugated Metal Panels while ensuring safety, efficiency, and sustainability in their projects.

Perforated corrugated metal panels have gained popularity due to their sleek aesthetic and practical applications in construction and design. However, these panels encounter several structural challenges that need careful consideration. One of the primary issues is the risk of reduced structural integrity. The perforations, while allowing for ventilation and light, can compromise the panel's ability to withstand heavy loads or high winds, particularly if not engineered properly. This can lead to deformation, buckling, or even failure in severe weather conditions.

Another significant concern relates to water ingress and corrosion. The perforations, if not adequately treated or sealed, can allow moisture to penetrate the panel’s surface. Over time, this can lead to rust and degradation, undermining the panel's durability and lifespan. Proper maintenance and the selection of corrosion-resistant materials are essential to mitigate these risks. Furthermore, careful design considerations, including the spacing and size of perforations, can significantly impact the overall strength and performance of the panels, ensuring that they serve their intended purpose without compromising on safety.

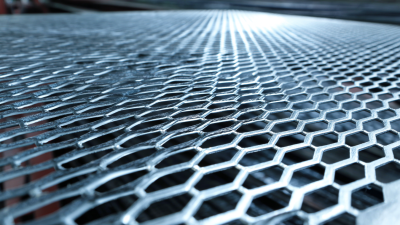

When it comes to employing perforated corrugated metal panels in construction, achieving optimal acoustic performance poses significant challenges. Industry studies indicate that while perforated panels can effectively reduce noise in certain applications, the design and configuration play a critical role in their efficacy. The NIST (National Institute of Standards and Technology) reports that the sound absorption coefficient of perforated materials can vary dramatically based on hole size, percentage of open area, and the backing material used. For instance, panels with a higher percentage of open area often yield better acoustic results, but they may compromise structural integrity or durability.

Moreover, the interplay between perforation patterns and the frequency of sound waves is a crucial factor that cannot be overlooked. According to a report from the Acoustical Society of America, the optimal performance of perforated metal panels occurs when their specifications align with the intended acoustic requirements of the space. Unfortunately, many designs fail to consider these acoustic dynamics, resulting in panels that do not adequately mitigate noise. This gap highlights the need for a thorough understanding of acoustic principles when integrating perforated corrugated metal panels into buildings, emphasizing the importance of collaboration between architects and acoustical engineers to achieve desired outcomes.

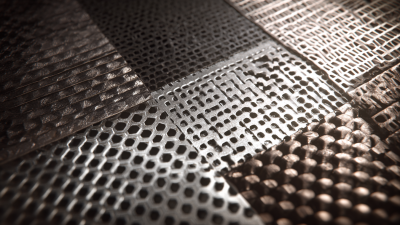

Perforated corrugated metal panels have gained popularity in various construction and architectural applications, but one of the primary challenges they face is durability, particularly concerning weathering and wear. According to a report by the Metal Construction Association, metal roofing systems can experience significant degradation when exposed to harsh environmental conditions if not properly treated. Factors such as UV radiation, high temperatures, and moisture can lead to corrosion and deterioration of the perforated surfaces, reducing their functional and aesthetic longevity.

Perforated corrugated metal panels have gained popularity in various construction and architectural applications, but one of the primary challenges they face is durability, particularly concerning weathering and wear. According to a report by the Metal Construction Association, metal roofing systems can experience significant degradation when exposed to harsh environmental conditions if not properly treated. Factors such as UV radiation, high temperatures, and moisture can lead to corrosion and deterioration of the perforated surfaces, reducing their functional and aesthetic longevity.

Moreover, research from the American Galvanizers Association highlights that unprotected perforated metals are particularly vulnerable to rust and degradation over time. In coastal areas, for instance, the combination of saltwater and humidity can severely shorten the lifespan of these materials. The use of protective coatings is crucial; studies have shown that galvanized or powder-coated finishes can enhance the durability of perforated panels by as much as 75%, effectively shielding them from weather-related wear. Ensuring robust maintenance protocols and selecting the appropriate materials based on local environmental conditions are essential steps for maximizing the durability of perforated corrugated metal panels.

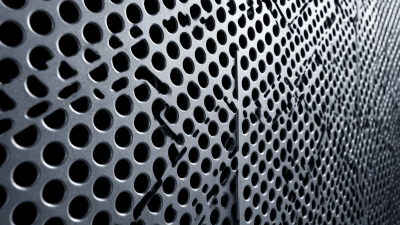

When it comes to the installation of perforated corrugated metal panels, one of the primary challenges lies in properly aligning and securing the panels. This process demands precision and careful consideration, as any misalignment can lead to structural issues or even costly rectifications later. The unique shape and perforation of these panels mean that standard mounting techniques may not always apply, necessitating the use of specialized installation methods. Ensuring that the panels sit flush against the underlying structure requires meticulous attention to detail, which can be particularly daunting on uneven surfaces commonly found in rooftop projects.

In addition to alignment, proper securing is crucial to the integrity of the installation. Common practices include the use of mounting wires and fasteners, where simplicity can be deceptive. For example, while plastic zip ties may seem sufficient for securing wires on flush-mounted arrays, they can become a point of failure if not regularly inspected or properly tightened. This underscores the importance of reliable securing methods, especially following recent guidelines issued for solar panel installations to prevent accidents. Addressing these installation difficulties effectively can make a significant difference in the overall performance and safety of the panel systems.

| Challenge | Description | Impact on Installation | Mitigation Strategies |

|---|---|---|---|

| Misalignment of Panels | Panels may not line up correctly due to uneven surfaces or measurement errors. | Can lead to water ingress and reduced aesthetic appeal. | Use laser alignment tools and double-check measurements prior to installation. |

| Panel Securing | Difficulty in securing panels tightly enough to avoid vibrational loosening. | Risk of panels detaching or becoming loose over time. | Use appropriate fasteners and consider additional rigid backing. |

| Weight of Panels | Heavy panels can be difficult to handle and position during installation. | May require more labor or machinery to position accurately. | Utilize hoisting equipment or assistive technology to manage weight. |

| Environmental Factors | Wind, rain, or extreme temperatures can affect the installation process. | Risk of improper fitting due to shifting materials. | Plan installations for calmer weather conditions and adjust as needed. |

| Tools and Equipment | Inadequate or improperly calibrated tools can lead to errors. | Increased risk of damage to panels or substructures. | Regularly inspect and calibrate tools before starting installations. |

Perforated corrugated metal panels are increasingly popular in modern architecture due to their aesthetic appeal and functional advantages, such as light filtration and ventilation. However, maintaining these surfaces presents unique challenges. Perforated surfaces can trap dirt and debris in their holes, making cleaning efforts more labor-intensive. According to a study by the Metal Building Manufacturers Association, improper maintenance can lead to significant deterioration, impacting not only the appearance but also the structural integrity of the panels.

To effectively clean perforated metal panels, it is recommended to use a low-pressure washing system to avoid damaging the material. Additionally, regular inspections are crucial for identifying signs of wear or corrosion early. Addressing small repairs immediately can prevent larger issues from developing, which can save time and costs in the long run. Utilizing specialized cleaning products that cater to metal surfaces can also enhance the cleaning efficiency while preserving the finish.

Understanding the specifics of maintaining these materials is essential for building owners and facility managers. By implementing a proactive maintenance plan, including periodic cleanings and timely repairs, one can ensure the longevity and performance of perforated corrugated metal panels, keeping them looking great and functioning well over time.