The utilization of Perforated Plate Steel has gained significant traction across various industries due to its unique properties and versatility. According to a report by the Global Steel Market Research Institute, the demand for perforated metal products is projected to grow by 4.5% annually, fueled by advancements in manufacturing technologies and increasing applications in construction, HVAC systems, and decorative elements. However, the adoption of Perforated Plate Steel comes with its own set of challenges, including issues related to material integrity, cost management, and design limitations.

As industries continue to explore innovative solutions while leveraging the benefits of perforated materials, understanding these challenges becomes paramount. This article delves into the multifaceted nature of Perforated Plate Steel to shed light on the benefits and the hurdles faced by engineers and manufacturers alike.

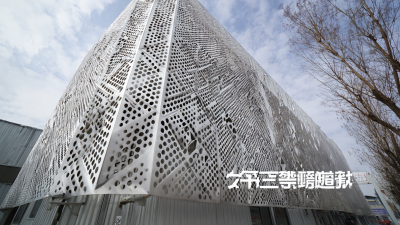

Perforated plate steel has gained popularity in various construction applications due to its versatility and aesthetic appeal. However, its impact on structural integrity cannot be overlooked. Using perforated plate steel introduces unique challenges that must be carefully considered during the design and engineering phases. The presence of holes reduces the cross-sectional area of the material, which can affect load-bearing capacities. Structural engineers must thoroughly analyze the stress distribution around the perforations to ensure that the steel will perform adequately under intended loads.

Additionally, the performance of perforated plate steel in a construction project is influenced by factors such as corrosion resistance and fatigue strength. As the material is subjected to environmental stressors, the risk of degradation increases, particularly around the perforated areas. It is essential to select the appropriate coating and treatment methods to enhance the longevity of the steel. Moreover, understanding the impact of perforations on the overall stiffness and vibration characteristics of the structure is crucial. In applications where stability and durability are paramount, careful consideration of these factors will ensure that the use of perforated plate steel contributes positively to the structural integrity of the building.

The production of perforated plate steel involves intricate manufacturing processes that present several key challenges. One significant issue is the precision required in perforation, as even minor deviations can lead to structural weaknesses and compromises in functionality. According to a report by Smithers Pira, the global market for perforated metals is expected to reach $1.05 billion by 2025, driven by growing demand in industries like construction and automotive. This necessitates advanced manufacturing techniques to maintain consistency and quality through rigorous tolerance levels.

Another challenge is the wear and tear on machinery caused by high-volume perforation processes. The use of high-strength steel can enhance durability but often leads to increased machine downtime and maintenance costs. A study by Research and Markets indicates that the average maintenance costs for perforating machinery can account for as much as 15-20% of the operational budget. Manufacturers must strike a balance between material selection and operational efficiency, which often requires innovative solutions and investment in advanced technologies to minimize downtime and maintain production quality.

| Challenge | Description | Impact | Potential Solutions |

|---|---|---|---|

| Material Sourcing | Difficulties in obtaining high-quality raw materials for production. | Delays in production and increased costs. | Establish long-term contracts with reliable suppliers. |

| Machinery Limitations | Inadequate or outdated machinery for perforation processes. | Reduced production efficiency and increased maintenance costs. | Invest in modern machinery or upgrade existing equipment. |

| Quality Control | Challenges in maintaining consistent perforation quality. | Customer dissatisfaction and potential return of products. | Implement regular quality checks and staff training. |

| Design Complexity | Complications arising from intricate designs required by clients. | Longer lead times and challenges in meeting specifications. | Enhance design capabilities in the engineering team. |

| Waste Management | Excessive waste generated during the perforation process. | Increased costs and environmental impact. | Implement waste reduction strategies and recycling programs. |

Perforated plate steel is increasingly popular in various applications due to its versatility and aesthetic appeal. However, one of the primary challenges associated with its usage is maintaining corrosion resistance. This type of steel features numerous holes that, while beneficial for weight reduction and airflow, can create vulnerabilities. When these perforations are exposed to moisture or corrosive elements, the risk of rust and degradation increases significantly. As such, selecting the right finish or coating is crucial for enhancing durability, with options ranging from galvanizing to powder coating that can effectively shield the surface.

Regular maintenance is essential to prolong the life of perforated plate steel structures. Implementing a thorough inspection routine can help identify early signs of corrosion, allowing for timely intervention. Cleaning the surface to remove debris and contaminants, especially in environments prone to rust, is crucial. Additionally, applying protective treatments periodically can prevent deterioration. By prioritizing corrosion resistance and effective maintenance practices, users can ensure that perforated plate steel remains both functional and attractive, serving its intended purpose for years to come.

The usage of perforated plate steel in various industries brings about several regulatory standards and compliance issues that must be navigated carefully. Organizations involved in the manufacturing and application of these materials must adhere to safety standards set forth by bodies such as the ASTM and ANSI. These regulations ensure that the perforated plates meet specific requirements concerning strength, durability, and safety in use, particularly in construction and engineering sectors where structural integrity is crucial.

Tip: Always stay updated with the latest regulatory frameworks relevant to your industry. Attend workshops or webinars that focus on compliance standards to better understand how they affect your operations.

Perforated plate steel plays a significant role in various industrial applications, offering unique characteristics such as lightweight construction, aesthetic appeal, and noise reduction. From automotive manufacturing to architectural design, the economic implications of using perforated plate steel are profound.

According to a recent report by the Global Steel Market Analysis, the demand for perforated steel is projected to grow by approximately 5% annually, driven by the need for cost-effective materials that enhance energy efficiency. By implementing perforated plates, businesses can reduce material wastage, leading to lower production costs and minimized environmental impact.

Tip: When considering the usage of perforated plate steel, be sure to evaluate the initial investment against long-term savings in material and operational costs. An in-depth lifecycle analysis can help determine the overall financial benefits of your project.

Additionally, the versatility of perforated plate steel allows for customized solutions that cater to specific industrial needs. Recent data from the Steel Manufacturers Association indicates that companies utilizing perforated steel can improve productivity by up to 15% due to its adaptability in various applications. With the rise of sustainable practices, choosing perforated plate steel becomes an even more appealing option for businesses seeking to showcase their commitment to environmental responsibility.

Tip: Explore various perforation patterns and hole sizes to optimize the benefits for your particular application. Tailoring these factors can enhance performance while potentially reducing energy consumption during manufacturing.