When it comes to sourcing materials for industrial and commercial applications, the choice of perforated stainless steel mesh is often pivotal. This versatile material offers a wealth of benefits, including durability, corrosion resistance, and aesthetic appeal. However, buyers frequently face a range of challenges that can complicate their purchasing decisions.

From understanding the various types of perforation patterns and hole sizes to assessing the appropriate gauge for specific applications, making an informed choice can be daunting. Additionally, the comparison of suppliers, quality standards, and pricing can further cloud the decision-making process.

This blog aims to dissect the challenges faced by buyers of perforated stainless steel mesh, providing insights into the critical factors that should be considered when evaluating options in the marketplace. By exploring these aspects, we hope to empower potential buyers to navigate their choices with greater confidence and clarity.

When purchasing perforated stainless steel mesh, several key factors must be considered to ensure that the material meets specific project requirements. First, the hole size and pattern are crucial aspects. Depending on the application, buyers may need small holes for filtration purposes or larger ones for airflow and visibility. Understanding the intended use will guide buyers in selecting the appropriate hole dimensions and patterns that optimize functionality.

Another important consideration is the gauge and thickness of the stainless steel. Thicker materials tend to offer greater durability and resistance to deformation, which is ideal for high-stress applications. Additionally, buyers should evaluate the grade of stainless steel, as different grades provide varying levels of corrosion resistance and strength, influencing the longevity of the mesh in diverse environments. By paying attention to these factors, buyers can make informed decisions that align with their specific needs and ensure that their perforated stainless steel mesh performs effectively in its intended application.

When seeking perforated stainless steel mesh, buyers often hold various misconceptions that can lead to challenges in their purchasing decisions. One common belief is that all perforated metals are interchangeable, with no significant difference in performance or application. In reality, the specific properties of the stainless steel, such as the alloy composition and the pattern of perforations, can drastically affect corrosion resistance, strength, and aesthetic appeal. According to a report by the International Stainless Steel Forum, different grades of stainless steel can have varying sustainabilities, with some grades exhibiting nearly double the lifespan in certain environments compared to others.

When seeking perforated stainless steel mesh, buyers often hold various misconceptions that can lead to challenges in their purchasing decisions. One common belief is that all perforated metals are interchangeable, with no significant difference in performance or application. In reality, the specific properties of the stainless steel, such as the alloy composition and the pattern of perforations, can drastically affect corrosion resistance, strength, and aesthetic appeal. According to a report by the International Stainless Steel Forum, different grades of stainless steel can have varying sustainabilities, with some grades exhibiting nearly double the lifespan in certain environments compared to others.

Another misconception is the assumption that perforated stainless steel mesh is prohibitively expensive and thus only suitable for high-end applications. In truth, the cost of perforated mesh can vary widely based on several factors, including the type of material used, the size of the perforations, and the quantity ordered. A study from the Metal Research Institute found that bulk purchasing can significantly decrease the cost per square foot of mesh, making it a viable option for both large industrial applications and smaller projects. By understanding these nuances, buyers can make informed decisions that align with both their budget and their project's specific needs.

When it comes to perforated stainless steel mesh, understanding the various types available is crucial for buyers looking to meet specific needs in their projects. The primary categories include round holes, square holes, and decorative designs, each serving different functional and aesthetic purposes.

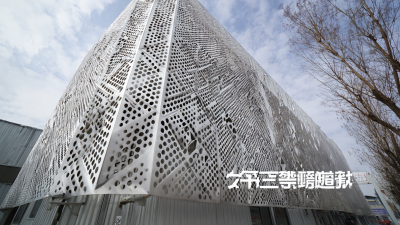

Round hole mesh is commonly used in industrial applications for ventilation and filtration due to its strength and efficiency in allowing air or liquid to pass through while maintaining structural integrity. Square hole variants, on the other hand, provide a uniform appearance and are often favored in architectural designs for facades and railings.

Additionally, there are specialized perforated meshes with unique patterns that cater to niche applications such as sound dampening or privacy screens. The market for perforated metal sheets is expected to grow significantly, driven by diverse sectors including architecture and automotive industries, signaling an increasing demand for customizable and versatile solutions.

Buyers should not only consider the hole shape but also the thickness and material grade of the mesh to ensure it meets their performance requirements, especially in environments that experience varying temperatures and conditions.

When evaluating perforated stainless steel mesh, buyers often encounter significant challenges in assessing both quality and performance. One primary concern lies in the diverse range of materials and finishes available. Stainless steel, for instance, can vary in grades, each affecting the mesh’s durability, resistance to corrosion, and overall aesthetic appeal. Buyers must be well-versed in these specifications to make informed decisions, as overlooking crucial details may lead to inadequate products that fail to meet their operational needs.

Furthermore, performance assessment poses a complex challenge, particularly regarding the mesh's suitability for specific applications. Different projects may require distinct hole sizes, patterns, and thicknesses—factors that directly influence the mesh's functionality. Buyers can also struggle with ensuring that the products they choose maintain structural integrity under various conditions, such as extreme temperatures or chemical exposure. Without proper knowledge or a reliable vendor, sourcing the right perforated stainless steel mesh can become a daunting task, resulting in costly delays and unsatisfactory outcomes in their applications.

When selecting a supplier for perforated stainless steel mesh, prospective buyers must navigate various challenges to ensure quality and reliability. The global market for stainless steel mesh is projected to grow significantly, with a compound annual growth rate (CAGR) of around 5.1% from 2021 to 2028, according to industry reports. This growth highlights the increasing demand for high-performance materials across sectors such as construction, automotive, and industrial manufacturing. Buyers should prioritize suppliers who not only understand these trends but also possess proven experience in the field.

One critical factor to consider is the supplier's material certification and quality assurance processes. According to a report by MarketsandMarkets, approximately 30% of buyers reported receiving subpar quality products due to lack of stringent quality control measures from suppliers. Therefore, engaging with suppliers who provide detailed compliance certificates, such as ISO standards, can mitigate risks. Furthermore, it’s beneficial to evaluate customer reviews and case studies that demonstrate a supplier's capability to meet specific perforation patterns and material gauges, ensuring that their products meet the required technical specifications for your applications.

| Dimension | Hole Size (inches) | Thickness (mm) | Material Grade | Application Area | Supplier Rating (out of 5) |

|---|---|---|---|---|---|

| 2' x 4' | 0.125 | 1.0 | 304 | Construction | 4.5 |

| 3' x 3' | 0.5 | 1.5 | 316 | Filtration | 4.0 |

| 4' x 8' | 0.25 | 1.0 | 304 | Industrial | 4.7 |

| 2' x 6' | 0.375 | 1.2 | 316 | Architectural | 4.3 |

| 4' x 10' | 0.0625 | 0.8 | 304 | Automotive | 4.6 |