Perforated Plate Steel is gaining popularity across various industries by 2026. This material offers unique benefits that enhance its applications. Its lightweight and versatile design make it a top choice for numerous projects.

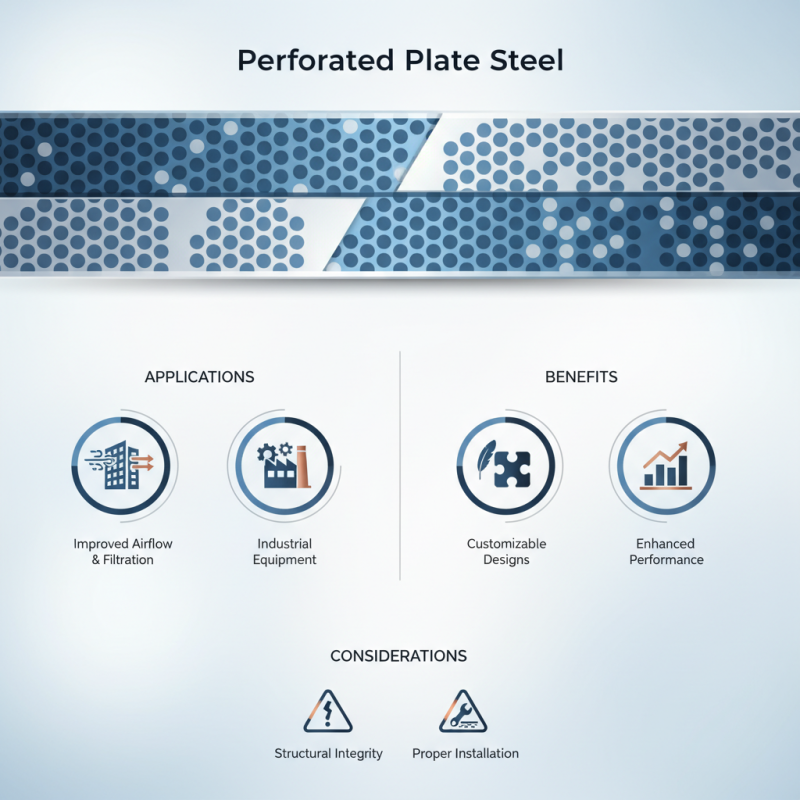

Manufacturers are adopting Perforated Plate Steel for improved airflow and filtration. This innovative material supports a variety of uses, from architectural elements to industrial equipment. The perforations can be customized, allowing for creative and functional designs.

Despite its growing use, challenges remain. Some users may overlook structural integrity. Proper installation is crucial for maximum performance. Understanding these factors is essential for effective applications of Perforated Plate Steel in the modern world.

Perforated plate steel is a versatile material. It features numerous holes or slots, allowing air, light, and sound to pass through. This unique design also reduces weight without compromising strength. Manufacturers create perforated plates by using CNC machines or punch presses. They choose materials like stainless steel or mild steel based on the application.

The production process involves precise measurements. It begins with the selection of sheet metal. Then, machines accurately form holes in various patterns. Nonetheless, achieving uniformity can be challenging. Some manufacturers may face inconsistencies in hole size or spacing. This often needs adjustment during the production stage.

Applications for perforated plate steel are abundant. It is commonly used in architectural designs, filtration systems, and soundproofing. For instance, in construction, it serves as decorative facades. However, it’s crucial to consider factors like material corrosion. Proper selection and maintenance are vital to ensure longevity.

Perforated plate steel finds extensive use in various industries. Manufacturers utilize it for its durability and versatility. The holes in the metal allow for air, light, and sound to pass through. This feature is beneficial in many applications.

In the construction sector, perforated plates are vital for facades. They provide aesthetic appeal while allowing ventilation. In landscaping, they serve as grates and protectors against soil erosion. They also help in noise reduction, making urban living more comfortable.

Tips: When selecting perforated plate steel, consider the hole size and pattern. This choice greatly affects function. For indoor applications, think about corrosion resistance. A small investment goes a long way.

Furthermore, in the automotive industry, these plates are essential. They help in weight reduction, contributing to fuel efficiency. However, some designs may compromise structural integrity. It's important to find the balance.

| Application Area | Industry | Benefits | Material Type |

|---|---|---|---|

| Architectural Grilles | Construction | Aesthetic appeal, ventilation | Galvanized Steel |

| Filtration Systems | Manufacturing | Effective particle retention, durability | Stainless Steel |

| Sound Barriers | Transportation | Noise reduction, eco-friendly design | Aluminum |

| Shelving and Racking | Retail | Increased visibility, air circulation | Mild Steel |

| Walkways | Mining | Heavy-duty, slip resistance | Carbon Steel |

| Screens and Separators | Agriculture | High efficiency, easy maintenance | Stainless Steel |

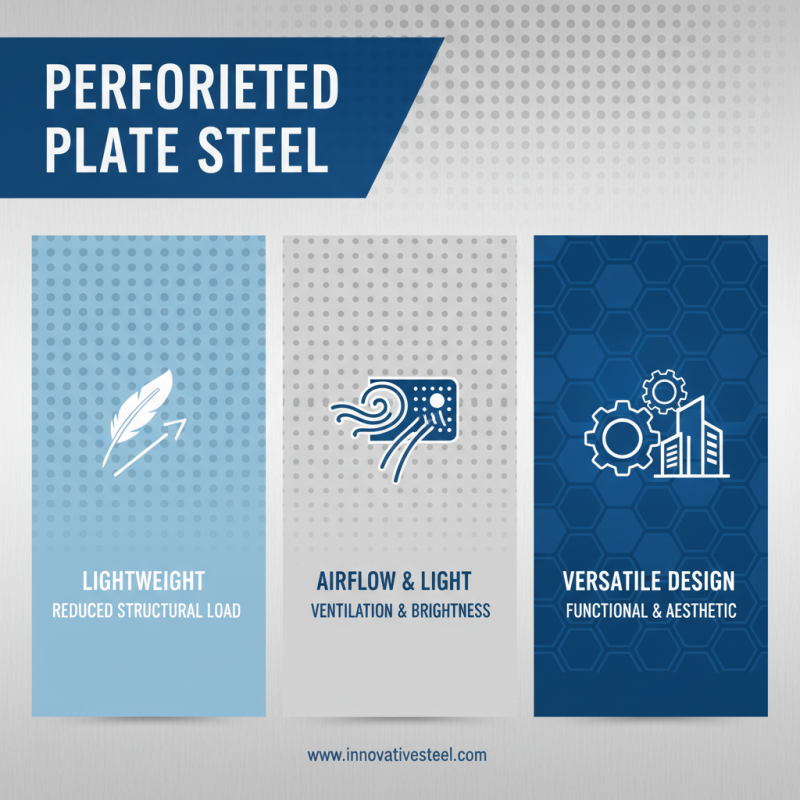

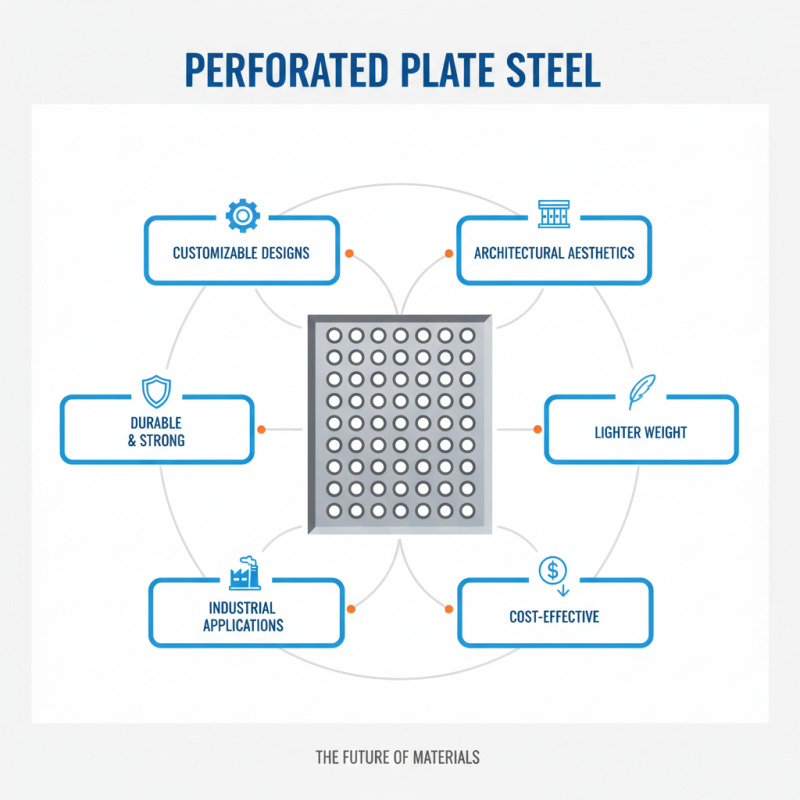

Perforated plate steel has gained attention in design and construction. Its unique features offer various benefits that enhance both functionality and aesthetics. One primary advantage is its lightweight nature. Builders can save on structural loads, making it easier to integrate into different projects. Also, the perforations allow for better airflow and light penetration. This is vital in applications like facades and partitions.

Another benefit lies in its versatility. Perforated steel can be customized in various patterns and sizes. Designers can create stunning visuals while maintaining structural integrity. This is ideal for modern architectural projects. However, choices must be made carefully. Not every design is suitable for every application, and this demands thoughtful planning.

Durability is a key aspect of perforated steel. It can withstand harsh environments, making it a practical choice for outdoor structures. However, maintenance is necessary over time. Corrosion can be a concern without proper treatment. Consequently, thoughtful considerations are essential when selecting the type of perforated steel for each project.

As we move into 2026, the perforated plate steel market is witnessing significant innovations. Recent reports indicate that demand in construction and architecture segments continues to surge. Lightweight structures benefit from perforated plates, offering both aesthetic appeal and functional versatility. According to market analysts, the global perforated plate steel market is projected to grow by 7% annually, driven by increased urbanization.

Sustainability is a key driver of innovation in this sector. Many manufacturers are adopting eco-friendly practices. They are focusing on sourcing steel from recycled materials. This shift not only reduces carbon footprints but also meets the growing consumer demand for sustainable products. Yet, challenges remain. The production process must be optimized to maintain quality while ensuring environmental standards.

Another trend is the customization of perforated plates to cater to specific applications. Industries are seeking unique designs and solutions. While this offers new opportunities, it can complicate the manufacturing process. Balancing standardization with customization is a task many in the industry still grapple with. As we look towards 2026, adaptability will be essential for success in the evolving perforated plate steel landscape.

Perforated plate steel is gaining traction in many industries. It offers distinct advantages over traditional materials. The plate can be customized easily, which helps in various applications. Its aesthetic appeal adds value in architecture and design. It often weighs less than solid alternatives, reducing transportation costs.

In contrast, traditional materials may not provide the same flexibility. They can be bulky and harder to shape. This limitation often leads to wasted resources. Additionally, traditional options can be heavy, making installations more difficult. However, some industries still prefer these materials for their reliability. They have a long history of use, which provides a sense of security.

While perforated plate steel is innovative, it is not without its challenges. The manufacturing process can sometimes produce inconsistent quality. This inconsistency may lead to structural concerns. In harsh environments, traditional materials might outperform. Thorough testing is vital for both to ensure safety and efficiency over time.