In the modern industrial landscape, the versatility of

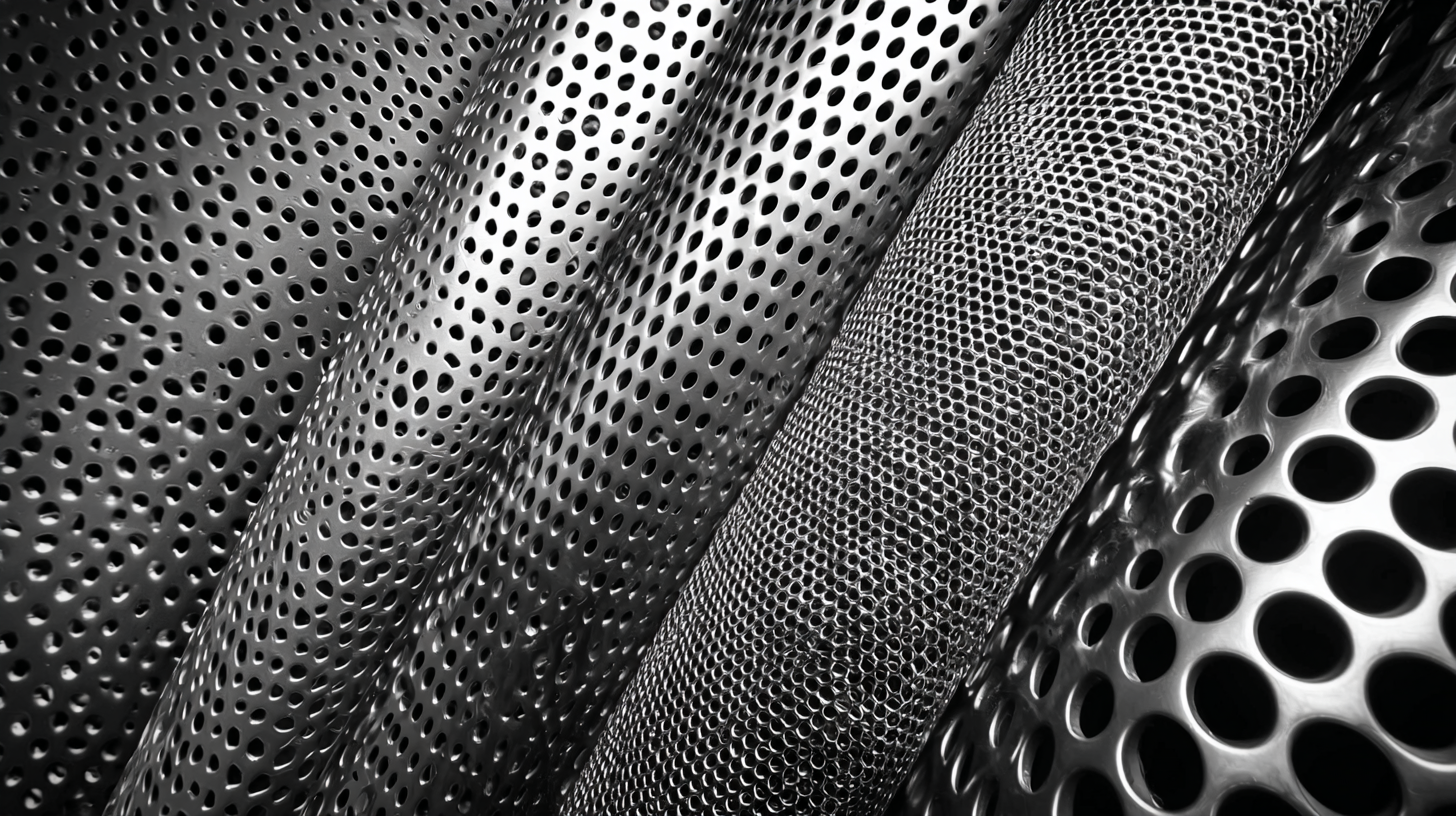

Perforated Metal Sheets has become increasingly evident, with applications spanning various sectors including manufacturing, construction, and environmental engineering. According to a recent industry report by Grand View Research, the global perforated metals market is expected to reach USD 3.36 billion by 2025, demonstrating a significant growth rate due to rising demand for lightweight yet durable materials.

These sheets, characterized by their unique hole patterns, are not only lauded for their aesthetic appeal but also for their functional benefits, such as improved airflow, sound attenuation, and material efficiency. As industries continue to innovate and prioritize sustainability, exploring the seven best applications for Perforated Metal Sheets reveals their pivotal role in enhancing both performance and design across a multitude of modern industrial applications.

These sheets, characterized by their unique hole patterns, are not only lauded for their aesthetic appeal but also for their functional benefits, such as improved airflow, sound attenuation, and material efficiency. As industries continue to innovate and prioritize sustainability, exploring the seven best applications for Perforated Metal Sheets reveals their pivotal role in enhancing both performance and design across a multitude of modern industrial applications.

Perforated metal sheets have become a staple in architectural design, offering both functional and aesthetic advantages. Their unique patterns and versatility allow architects to create visually striking facades while providing necessary structural benefits. For instance, these sheets can be employed as privacy screens that balance openness with seclusion in urban environments. The holes can be designed in various sizes and shapes, enabling creators to customize light filtration, ventilation, and even sound attenuation, making spaces more adaptable to user needs. In addition to practical applications, perforated metal sheets also contribute to sustainable design principles. Their use promotes energy efficiency by allowing natural light to enter a building while reducing reliance on artificial lighting. The integration of these elements not only enhances the building's aesthetic appeal but also aligns with contemporary eco-friendly practices. The combination of form and function exemplifies the modern architect's goal of creating spaces that are both beautiful and responsive to environmental challenges, underscoring the significance of perforated metal sheets in today's architectural landscape.

Perforated metal sheets have emerged as a crucial component in modern filtration systems across various industries. Their unique perforation patterns allow for optimal fluid flow while simultaneously providing the necessary separation of particles. According to a report by the Global Filtration Market, the filtration sector is projected to reach $39.68 billion by 2025, highlighting the growing demand for effective filtration solutions where perforated metal sheets play a vital role.

In water treatment facilities, for instance, perforated metal sheets serve as essential filters that enhance water quality by removing contaminants and sediments. The perforation sizes can be precisely engineered to target specific particle sizes, which is essential for compliance with stricter environmental regulations. A study published in the Journal of Hazardous Materials indicates that the use of perforated filters can improve the efficiency of filtration processes by up to 30%, making them a preferred choice in both industrial and municipal wastewater treatment systems.

Moreover, in the chemical processing industry, these sheets are used in various filtration applications to handle toxic materials effectively. Their durability and resistance to corrosive substances ensure longevity and reduced maintenance costs. A market analysis by IBISWorld noted that companies engaged in these filtration practices witness significant operational cost savings, attributing up to 20% of their budget to preventive maintenance, thanks to the reliable performance of perforated metal sheets. Implementing these innovative solutions not only elevates filtration efficiency but also contributes to the overall sustainability goals of modern industries.

Perforated metal sheets are rapidly gaining traction in modern industry, particularly due to their ability to enhance safety and aesthetics in industrial equipment. Recent market reports indicate that the perforated metal sheets market is projected to reach $5.3 billion by 2035, largely driven by their versatile applications in architecture, automotive, and various industrial sectors. The functionality of these sheets allows for increased ventilation and light transmission while reducing weight, making them ideal for use in equipment such as safety barriers, machinery covers, and custom enclosures.

Moreover, the aesthetic appeal of perforated metal can significantly elevate the design of industrial equipment. Organizations are increasingly recognizing the importance of combining form with function. This trend is further highlighted by the growing demand for innovative, visually appealing solutions that maintain operational efficiency. The industrial sector is evolving, and with it, the materials used. As more companies adopt perforated metal sheets, they contribute not only to the safety of their products but also to a modern aesthetic that aligns with current design philosophies.

Perforated metal sheets have emerged as a versatile solution in modern industry, especially in the realm of acoustic panels and soundproofing applications. Their unique design, characterized by a series of holes or slots cut into the metal, allows for impressive sound absorption properties. This feature enables architects and designers to create spaces that effectively manage sound levels, making them ideal for concert halls, recording studios, and open offices where noise control is paramount.

The efficacy of perforated metal sheets in soundproofing lies in their ability to disrupt sound waves. When sound waves hit the perforated surface, they enter the holes and are partially absorbed by the underlying materials, reducing echo and reverberation. Additionally, the choice of materials, hole sizes, and spacing can be customized to achieve the desired acoustic performance. This adaptability has led to widespread use in various industries, enhancing both functional performance and aesthetic appeal in environments where sound management is critical. As the demand for effective noise reduction solutions continues to grow, perforated metal sheets remain at the forefront of innovation in acoustic engineering.

Perforated metal sheets have emerged as essential components in modern green building practices, offering sustainable solutions across various industries. Their ability to enhance energy efficiency while maintaining aesthetic appeal makes them a preferred choice among architects and builders. The perforations allow for natural ventilation, reducing the need for mechanical cooling systems, which lowers energy consumption.