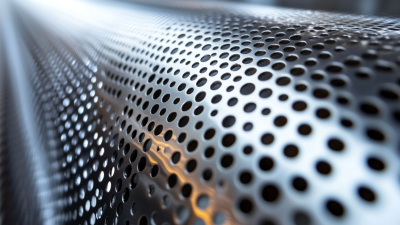

In today's fast-paced industrial landscape, the versatility and durability of materials play a crucial role in enhancing efficiency and functionality. Stainless Perforated Sheets have emerged as a cornerstone in various applications, ranging from architecture to filtration systems. According to a recent market report by Smithers Pira, the global perforated metal market is projected to reach $3.3 billion by 2025, driven by the growing demand in sectors such as construction and automotive. The unique combination of strength, aesthetic appeal, and customization options makes Stainless Perforated Sheets a favored choice among engineers and designers. As industries continue to innovate, understanding the essential benefits of using these sheets will be vital for making informed decisions that align with both performance and sustainability goals.

Stainless perforated sheets have become indispensable in various modern applications due to their unique characteristics, which enhance performance and versatility. These sheets are made from high-quality stainless steel, offering excellent corrosion resistance—an essential trait for industries such as food processing and chemical manufacturing. According to a report by Grand View Research, the global stainless steel market is projected to reach $125.96 billion by 2027, driven in part by the increasing demand for durable materials in industrial applications. The lightweight nature of these sheets, combined with their strength, allows for easy handling and installation, significantly improving operational efficiency.

Additionally, their customizable hole patterns provide aesthetic appeal while maintaining functionality. The ability to control airflow and light transmission makes stainless perforated sheets ideal for architectural designs and ventilation systems. A study from the American Institute of Steel Construction highlights that perforated materials can reduce weight by approximately 50% without sacrificing structural integrity, which is crucial for energy efficiency in buildings. By leveraging these key characteristics, industries can optimize performance while sustaining long-term resilience in their applications.

| Benefit | Description | Applications |

|---|---|---|

| Durability | Stainless perforated sheets resist corrosion and wear, making them suitable for demanding environments. | Industrial machinery, outdoor structures |

| Aesthetic Appeal | These sheets offer a modern and stylish look, enhancing the visual appeal of projects. | Architectural facades, interior design |

| Lightweight | Stainless perforated sheets are lighter than solid sheets, making them easier to handle and install. | Transport applications, wall partitions |

| Versatility | Available in various hole sizes and patterns, suitable for numerous applications. | Screens, filters, and sound barriers |

| Easy Maintenance | They are easy to clean and maintain, ensuring longevity and functionality. | Food processing, medical equipment |

| Eco-Friendly | Stainless steel is recyclable, making it an environmentally conscious choice. | Green buildings, sustainable design |

| Enhanced Safety | Perforated sheets provide safety without compromising visibility and airflow. | Security grilles, railing infills |

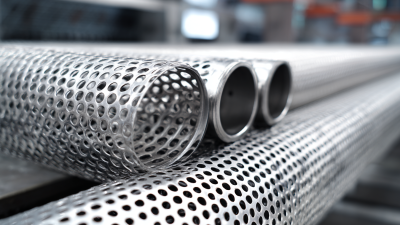

The manufacturing process of stainless perforated sheets involves several crucial steps that ensure the final product meets the exact specifications required for modern applications. Initially, high-quality stainless steel sheets are selected for their durability and resistance to corrosion. These sheets are then subjected to perforation, where precise patterns of holes are created using advanced machinery. Techniques such as rotary die stamping or laser cutting are commonly employed, allowing manufacturers to achieve intricate designs while maintaining tight tolerances.

The manufacturing process of stainless perforated sheets involves several crucial steps that ensure the final product meets the exact specifications required for modern applications. Initially, high-quality stainless steel sheets are selected for their durability and resistance to corrosion. These sheets are then subjected to perforation, where precise patterns of holes are created using advanced machinery. Techniques such as rotary die stamping or laser cutting are commonly employed, allowing manufacturers to achieve intricate designs while maintaining tight tolerances.

After perforation, the sheets undergo a thorough cleaning process to remove any debris or contaminants that may have accumulated during production. This step is vital in maintaining the integrity of the surface and ensuring optimal performance in various environments. Finally, the sheets may be further processed through finishing techniques, such as polishing or coating, to enhance their aesthetic appeal and functional properties.

With this careful attention to detail, stainless perforated sheets are not only functional but are also tailored to meet the diverse needs of industries ranging from construction to filtration.

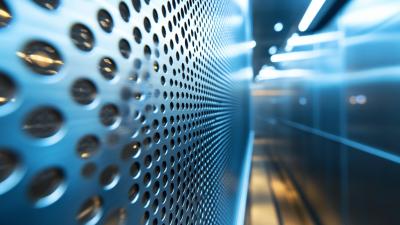

Stainless perforated sheets offer versatile applications across various industries, thanks to their unique combination of strength, lightweight design, and aesthetic appeal. In construction, these sheets are often utilized for façade elements, allowing for air circulation while providing visual interest. They are particularly effective in creating structures that blend functionality with modern design, enhancing both safety and style.

Stainless perforated sheets offer versatile applications across various industries, thanks to their unique combination of strength, lightweight design, and aesthetic appeal. In construction, these sheets are often utilized for façade elements, allowing for air circulation while providing visual interest. They are particularly effective in creating structures that blend functionality with modern design, enhancing both safety and style.

In the food industry, stainless perforated sheets are valuable for their ease of cleaning and resistance to corrosion, making them ideal for use in equipment and surfaces where hygiene is paramount. The perforations allow for efficient drainage and ventilation, which are critical for maintaining food quality. Additionally, their durability ensures long-lasting performance in demanding environments.

Tips: When selecting perforated sheets for specific applications, consider the hole size and pattern to achieve the desired balance between transparency and strength. It's also essential to evaluate the sheet thickness based on the structural requirements of your project to ensure optimal performance. Lastly, always prioritize materials that are easy to maintain, especially in industries where hygiene is critical.

Stainless perforated sheets are becoming increasingly vital in various modern applications due to their notable cost-effectiveness. Unlike traditional materials, these sheets boast longevity and resistance to corrosion, significantly reducing replacement costs over time. When considering the initial investment versus lifespan, stainless perforated sheets offer a compelling long-term financial advantage. Their durability ensures fewer maintenance expenses and replacements, making them an excellent choice for businesses looking to optimize their budgets.

Moreover, the bulk purchasing of stainless perforated sheets can amplify these savings, akin to buying household items in bulk to cut down on costs. By sourcing these sheets in larger quantities, companies can benefit from lower prices per unit, especially in a market where prices are gradually increasing due to supply chain factors. This strategic approach not only aids in immediate budget management but also secures proficiency in production processes by minimizing downtime associated with material replacements. Ultimately, investing in stainless perforated sheets is a wise decision for those seeking both quality and cost-efficiency in their operations.

In the realm of modern design, stainless perforated sheets stand out when compared to alternative materials due to their unique properties and multifaceted applications. One of the most compelling aspects is their potential for enhancing structural integrity while allowing for aesthetic versatility. Recent trends in architectural designs, such as the double-skin façades seen in projects like Moholt Allmenning Tower B, exemplify the increasing preference for perforated metallic sheets. These façades combine air chambers with perforated surfaces, which not only provide insulation but also create striking visual effects, making them a favored choice among designers.

In contrast to traditional materials such as wood or solid metal panels, stainless perforated sheets offer superior durability and resistance to corrosion. This attribute is particularly beneficial in environments exposed to harsh weather conditions, supporting structures in the automotive and industrial sectors. As the demand for sustainable and efficient building materials continues to rise, the perforated metal sheets market is projected to grow significantly, highlighting the shift towards more innovative construction practices. Their ability to balance functionality with contemporary aesthetics positions stainless perforated sheets as a vital component in the evolution of modern architecture.

This bar chart illustrates the importance of various benefits associated with stainless perforated sheets in modern applications. The ratings from 1 to 10 reflect how critical each benefit is perceived in comparison to other materials in design and functionality.