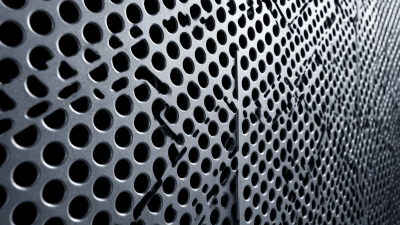

In the ever-evolving landscape of modern industry, the significance of efficient material handling and resource management cannot be overstated. One innovative solution that has garnered considerable attention is the use of Perforated Screen Panels. These versatile panels, characterized by their strategically placed holes, offer a myriad of benefits, including enhanced air and fluid flow, improved filtration, and efficient separation processes. From construction to food processing, Perforated Screen Panels are finding applications across various sectors, revolutionizing the way industries operate. Their ability to provide structural integrity while facilitating essential processes makes them an indispensable asset in achieving operational efficiency. This article delves into the multitude of advantages and diverse applications of Perforated Screen Panels, shedding light on why they are increasingly becoming a preferred choice in modern manufacturing and industrial settings.

Perforated screen panels have emerged as a critical component in modern industrial applications, significantly enhancing operational efficiency. These panels, characterized by their uniform holes, allow for optimal air and flow circulation while providing barrier functionality. In industries ranging from manufacturing to agriculture, their ability to filter and separate materials effectively is paramount, thus reducing operational bottlenecks and enhancing productivity.

One of the standout benefits of perforated screen panels is their versatility in design and application. They can be tailored to fit specific processes, whether it’s for drainage in construction or air filtration in ventilation systems. This adaptability means that industries can create bespoke solutions that meet their unique needs, resulting in cost savings and improved system performance. Additionally, the use of durable materials ensures longevity and reduced maintenance costs, making perforated panels a wise investment for businesses aiming to streamline their operations while boosting overall efficiency.

Perforated screen panels have become increasingly integral across various industries, offering numerous benefits such as enhanced ventilation, light filtration, and aesthetic appeal. In construction, these panels are utilized for facades, where they provide an innovative design element while promoting energy efficiency. Their ability to allow airflow reduces the reliance on mechanical ventilation systems, making buildings more sustainable and cost-effective.

In the manufacturing sector, perforated screen panels are widely used for filtration and separation processes. They serve as effective barriers for dust and particulate matter, improving air quality in industrial environments. Additionally, their durability makes them ideal for equipment shielding and safety enclosures, ensuring compliance with industry standards while maintaining operational efficiency. As industries continue to evolve, the versatility of perforated screen panels will likely lead to new applications, reinforcing their role in modern industrial solutions.

Perforated screen panels have gained significant traction in modern industries, especially when compared to traditional screening methods. According to a report by Grand View Research, the global market for screening equipment is expected to reach approximately $5.5 billion by 2025, driven largely by advancements in technology and the benefits offered by perforated panels. These panels enhance efficiency by providing superior airflow and concurrent material separation, resulting in increased processing rates—a crucial factor in industries such as mining, construction, and food processing.

In contrast to conventional screening techniques such as vibrating screens or woven wire meshes, perforated screen panels offer distinct advantages. They allow for precise sizing due to customizable hole patterns, which can significantly reduce material loss. The same report highlights that companies using perforated panels report up to a 30% improvement in output quality. Furthermore, due to their durable nature, perforated panels require less frequent replacement, leading to lower long-term operational costs and reducing downtime associated with maintenance—benefits that are becoming increasingly critical in an era where efficiency and productivity are paramount.

When it comes to selecting materials for perforated screen panels, durability and functionality are paramount. The choice of material directly impacts the panel's resistance to environmental conditions and its longevity in industrial applications. Common materials include stainless steel, aluminum, and high-density polyethylene (HDPE). Stainless steel is favored for its excellent strength, corrosion resistance, and ability to withstand high temperatures, making it ideal for demanding environments such as waste treatment plants and mining operations.

In addition to the primary material selection, the thickness and pattern of the perforations are also crucial factors. Thicker panels provide additional strength, which is essential for supporting heavy loads, while specific perforation patterns can enhance airflow and drainage, improving overall efficiency. The selection process should also consider factors such as ease of maintenance and cost-effectiveness. By carefully evaluating these elements, industries can ensure that their perforated screen panels not only meet immediate operational needs but also contribute to sustainability and cost savings over the long term.

Innovative designs in perforated screen panels are transforming the landscape of modern industry by effectively optimizing both functionality and aesthetics. These panels, recognized for their versatility, are used in applications ranging from architectural facades to industrial filtration systems. According to a recent report from MarketsandMarkets, the global perforated metal market is anticipated to grow from USD 1.1 billion in 2021 to USD 1.5 billion by 2026, emphasizing a rising demand for customized solutions that enhance operational efficiency while maintaining visual appeal.

Furthermore, advancements in manufacturing techniques are allowing for greater design flexibility. For instance, laser-cut technologies enable precise patterns and shapes that not only improve airflow and light filtration but also serve as striking design elements. The integration of enhanced materials, such as corrosion-resistant alloys, encourages durability and maintenance ease, making perforated panels a long-term investment for industries focused on sustainability and functionality. A study by ResearchAndMarkets highlights that 35% of architects and designers prioritize aesthetics in their projects, showing the importance of merging beauty with practical engineering in the current design ethos of perforated screen panels.