In today's rapidly evolving industrial landscape, the demand for innovative materials that enhance efficiency and durability is at an all-time high. Among these materials, the Perforated Stainless Steel Screen stands out due to its remarkable versatility and wide range of applications. As industries strive to optimize their processes and improve productivity, understanding the top applications of perforated stainless steel screens becomes crucial for engineers, designers, and decision-makers alike.

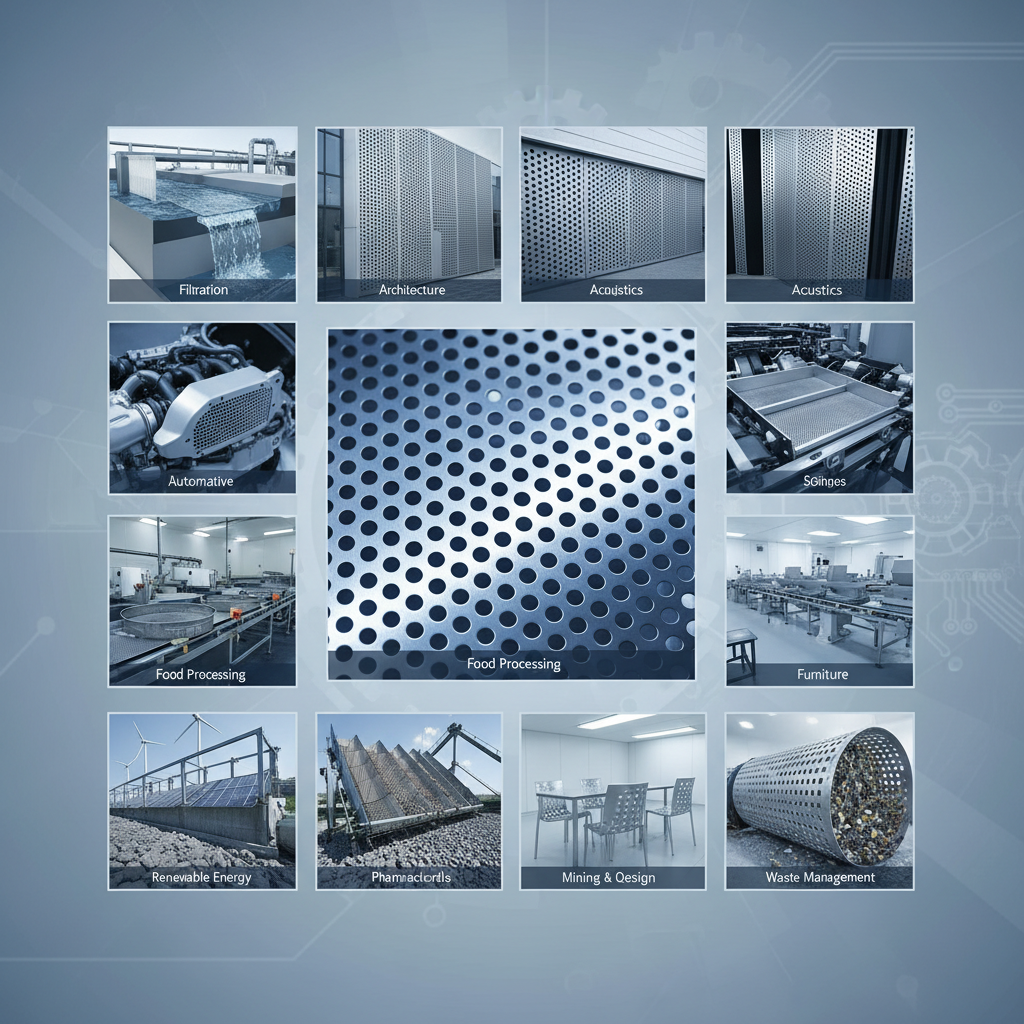

This article will explore the top ten applications of perforated stainless steel screens across various sectors, showcasing their invaluable contribution to modern industry. From filtration systems in water treatment facilities to architectural embellishments in construction, the multifunctional nature of these screens not only supports operational excellence but also fosters sustainability. Additionally, we will delve into the innovative designs and technological advancements that have allowed for more effective use of perforated stainless steel screens, underlining their importance in meeting the challenges of the 21st century. Join us as we uncover the transformative role of perforated stainless steel screens in shaping the future of various industries in 2025 and beyond.

Perforated stainless steel screens are essential components in various industrial applications due to their unique features. One of the standout properties is their high durability. Made from stainless steel, these screens are resistant to corrosion, which ensures a longer lifespan even in harsh environments. This durability makes them ideal for industries such as mining, waste management, and food processing, where materials often expose equipment to wear and tear.

Another key feature is their versatility in design. Perforated stainless steel screens can be customized with different hole sizes and patterns to suit specific needs, allowing for optimal performance in filtration and separation processes. This adaptability not only enhances functionality but also contributes to energy efficiency by reducing operational costs. Additionally, the smooth surface of these screens facilitates easy cleaning and maintenance, further underscoring their value in modern industrial applications. The combination of durability, versatility, and ease of maintenance positions perforated stainless steel screens as crucial elements across various sectors.

Perforated stainless steel screens are pivotal in industrial filtration, largely due to their enhanced efficiency and durability. The unique perforation patterns allow for optimal fluid flow while maintaining structural integrity, making them suitable for various applications, including water treatment, oil and gas, and food processing. Unlike traditional filtration materials, the resilience of stainless steel ensures that these screens withstand corrosive environments, thus extending their lifespan and reducing the need for frequent replacements.

In addition to their durability, perforated stainless steel screens are designed to provide precise filtration capabilities. The sizing of the perforations can be customized to target specific particles, which increases the overall effectiveness of the filtration process. This adaptability not only improves the purity of the end products but also contributes to energy savings by reducing the strain on industrial pumps and systems. As industries continue to seek more efficient and reliable filtration solutions, the role of perforated stainless steel screens becomes increasingly significant, setting a benchmark for performance and sustainability.

Perforated stainless steel screens play a crucial role in the food and beverage processing industry, offering significant advantages in terms of hygiene, efficiency, and durability. According to a report by MarketsandMarkets, the global perforated metal market is expected to reach USD 3.0 billion by 2026, with a notable rise in demand from the food sector. These screens are particularly beneficial in applications such as filtration, separation, and sorting, where maintaining product integrity is essential. Their ability to facilitate airflow and drainage while preventing contamination makes them ideal for processes like brewing and juice extraction.

When implementing perforated stainless steel screens, it's important to consider the size and shape of the perforations to optimize performance. For example, larger holes may enhance drainage efficiency but can also allow unwanted particulates to pass through. As a tip, regularly assessing the screen's condition and cleaning schedules can help maintain operational efficiency and extend the lifespan of the equipment.

Moreover, the choice of stainless steel grade is vital, as certain grades offer improved resistance to corrosion and staining, thereby ensuring higher standards of food safety. Always opt for screens that comply with relevant industry standards such as the FDA or NSF guidelines, ensuring that your processing meets the highest quality benchmarks.

This is a key point that deserves attention. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Etiam vehicula egestas nibh, nec tempor ligula elementum non. Quisque sit amet accumsan arcu. Suspendisse varius nunc in velit venenatis, at bibendum erat gravida. Sed tempor dolor quis turpis scelerisque, et dictum sem accumsan.

Pellentesque habitant morbi tristique senectus et netus et malesuada fames ac turpis egestas. Donec scelerisque ornare odio, at lacinia sapien aliquet vitae. This part highlights a significant aspect of the content. Aenean vel sapien et nulla fermentum varius.

Vivamus sit amet lacus vel odio venenatis sodales. Mauris cursus turpis at purus mattis, non cursus arcu laoreet. Remember: Always ensure that your content is engaging and informative. Proin aliquam odio sed sagittis ornare.

Perforated stainless steel screens have emerged as essential components across various industries, driven by their environmental benefits. A report from the World Steel Association highlights that stainless steel is 100% recyclable, making it a sustainable choice for manufacturers aiming to reduce their carbon footprint. By utilizing perforated stainless steel in applications such as filtration systems and sound absorption, industries can significantly minimize waste and promote a circular economy. This is particularly important as businesses are increasingly held accountable for their environmental impact.

In addition to recyclability, perforated stainless steel screens enhance energy efficiency. According to a study published by the International Energy Agency, using materials that allow for better airflow in industrial processes can lead to energy savings of up to 20%. This translates into reduced operational costs and lower greenhouse gas emissions. Industries such as food processing and water treatment benefit significantly from these screens, as they facilitate efficient resource extraction while ensuring minimal environmental disruption. The transition to perforated stainless steel not only represents a commitment to sustainability but also aligns with global goals for sustainable development and responsible production practices.

Perforated stainless steel screens play a crucial role across various industries, contributing to efficiency and environmental sustainability. The chart above illustrates the different applications of perforated stainless steel screens and the number of units utilized in each sector, highlighting their versatility and importance in modern industrial processes.