In the rapidly evolving industrial landscape, the demand for efficient filtration and separation solutions has heightened, leading to an increased focus on the development of advanced perforated screen panels. According to a recent market analysis by MarketsandMarkets, the global market for perforated materials is poised to grow at a compound annual growth rate (CAGR) of 5.3%, reaching an estimated value of $1.2 billion by 2025. This growth is attributed to the expanding applications in various sectors, including construction, manufacturing, and mining, underscoring the integral role of perforated screen panels in enhancing operational efficiency and product quality.

As industries seek innovative solutions to optimize production processes, the versatility and efficiency of perforated screen panels have become more critical than ever. These panels are not only pivotal in filtration systems but also serve various functions like ventilation, sound attenuation, and decorative features. Their customizable nature allows for tailored solutions that meet specific industrial needs. The ongoing advancements in materials and manufacturing techniques are set to revolutionize the availability and functionality of these panels. In this context, this article will explore the top ten perforated screen panels expected to lead the market in 2025, providing insights into their key features, applications, and the benefits they bring to diverse industries.

In 2025, the demand for perforated screen panels is evolving, driven by innovative materials that enhance performance and sustainability. Modern industries require solutions that not only meet functional specifications but also contribute to environmental goals. Advanced composites, such as recycled polymers and bio-based materials, are gaining traction. These alternatives provide the necessary strength and durability while minimizing ecological footprints, making them an attractive choice for eco-conscious manufacturers.

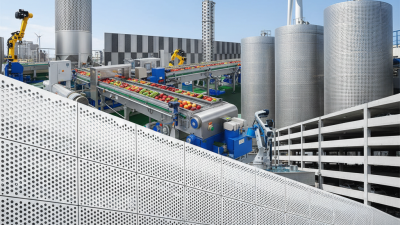

Additionally, the integration of smart technology into perforated screen panels is transforming their utility. Materials embedded with sensors can monitor parameters like airflow and material flow in real-time, providing valuable data for operational efficiency. Furthermore, coatings that enhance wear resistance and reduce maintenance needs are emerging, allowing for prolonged use in demanding industrial settings. These advancements mark a significant shift in how perforated panels are utilized, combining practicality with cutting-edge innovation to meet the dynamic requirements of modern industry.

This chart represents the innovative materials used in top perforated screen panels for industrial applications in 2025. The data illustrates the popularity and performance metrics of each material based on various industry feedback.

When selecting perforated screen panels for industrial applications, certain key features are critical to ensure efficiency and productivity. First and foremost, the material of the panels greatly impacts their durability and functionality. According to a report by Grand View Research, stainless steel panels are favored for their corrosion resistance and strength, making them ideal for high-pressure environments. Moreover, the choice of alloy can enhance wear resistance, especially in industries that involve abrasive materials, such as mining and manufacturing.

Another crucial feature is the hole pattern and size, which directly influences airflow and material handling. A study by MarketsandMarkets highlights that optimizing the perforation layout can improve material separation efficiency by up to 30%. In applications like filtration and screening, the correct perforation size ensures that the desired material passes while keeping unwanted debris at bay. Additionally, considerations such as panel thickness and acoustic insulation properties are essential; thicker panels can provide better sound dampening in industrial settings, which is increasingly important as companies strive to maintain a safer and more comfortable work environment.

As we look toward 2025, several brands are emerging as frontrunners in the perforated screen panel market, catering to diverse industrial needs. Companies like McNichols, perforated metal pioneer, continue to innovate with durable materials that offer both functionality and aesthetic versatility. Their extensive range of hole patterns and materials enables manufacturers to customize solutions tailored to specific operational demands, making them a go-to choice in various sectors.

Another leading brand is Locker Group, known for its commitment to sustainability and high-quality production. They have made significant strides in providing eco-friendly perforated screen panels, appealing to industries looking to minimize their environmental footprint. With a focus on advanced technology and exceptional customer service, Locker Group is setting new standards in the industry. Additionally, brands like Haver & Boecker and Finetec are also gaining traction, offering specialized products that address unique applications across manufacturing and architectural projects. Their emphasis on research and development ensures they remain at the forefront of the market, delivering innovative solutions for clients around the globe.

Perforated screen panels have become integral to various industrial applications, providing both functionality and aesthetic value. Their unique design allows for airflow, light passage, and sound absorption, making them highly sought after in sectors such as construction, automotive, and manufacturing. In the construction industry, these panels are often used for facades, offering a modern look while enhancing ventilation and natural lighting. Similarly, in automotive manufacturing, perforated screens assist in noise control and engine cooling, thus playing a crucial role in enhancing vehicle performance and comfort.

In addition to their structural benefits, perforated panels serve as versatile solutions in the manufacturing of machinery and equipment. They facilitate the separation of materials during production processes, improving efficiency and safety. As industries evolve, the demand for customized perforated panels tailored to specific operational needs continues to grow. Companies like Dinco Trading LLC exemplify this trend by providing premium aluminum solutions that cater to various industrial requirements, helping to drive progress in the UAE’s ambitious industrial landscape.

| Panel Type | Material | Hole Size (mm) | Thickness (mm) | Application Industry | Average Price ($) |

|---|---|---|---|---|---|

| Acoustic Panels | Aluminum | 5 | 2 | Construction | 150 |

| Screen Panels | Steel | 10 | 3 | Mining | 200 |

| Printed Panels | Plastic | 8 | 1.5 | Event Management | 120 |

| Grill Panels | Stainless Steel | 7 | 2.5 | Food Processing | 180 |

| Air Intake Panels | Aluminum | 6 | 4 | HVAC | 220 |

| Filter Panels | Fiberglass | 4 | 3 | Chemical Industry | 160 |

| Security Screens | Steel | 9 | 3.5 | Retail | 300 |

| Decorative Panels | Aluminum | 5 | 2 | Architecture | 160 |

| Vibration Isolation Panels | Plastic | 7 | 2 | Manufacturing | 140 |

| Mesh Panels | Fiberglass | 8 | 4 | Environmental | 175 |

The perforated screen panel technology is advancing rapidly, with innovative materials and designs driving industrial applications. As depicted in recent market projections, the perforated metal sheets market is expected to reach $5.3 billion by 2035, primarily fueled by demands in architecture, automotive, and industrial sectors. The adoption of perforated panels in various industries is not only a response to aesthetic needs but also a fulfillment of functional requirements such as ventilation and noise management.

Emerging trends highlighted at industry seminars, such as the DTS 2025, underscore a shift towards integrating high-definition displays with perforated technologies. Such advancements could revolutionize how these panels are utilized, allowing for improved functionality without compromising on aesthetics. Additionally, the Future Interfaces Group's research into tactile OLED screens indicates a potential for creating interactive and responsive environments using perforated designs, suggesting a future where industrial and architectural needs converge more seamlessly.