In the ever-evolving landscape of construction and manufacturing, selecting the right materials can significantly impact the success of any project. Among various materials available, the “Perforated Copper Sheet” stands out due to its superior conductivity, durability, and aesthetic appeal. According to a recent industry report from the Copper Development Association, the demand for perforated copper products is projected to grow by 15% annually through 2025, driven largely by advancements in architecture and electrical applications. This growth emphasizes the importance of understanding how to choose the best perforated copper sheet for specific needs.

Renowned expert in metallurgical processes, Dr. Emily Carr, notes, "The unique properties of perforated copper sheets make them indispensable in applications where both functionality and design are crucial." Her insights reflect the increasing relevance of perforated copper across diverse sectors, from HVAC systems to decorative panels. As we move towards 2025, it's essential for professionals in the field to be equipped with the knowledge required to make informed decisions about perforated copper sheets, taking into consideration factors such as hole patterns, sheet thickness, and intended usage.

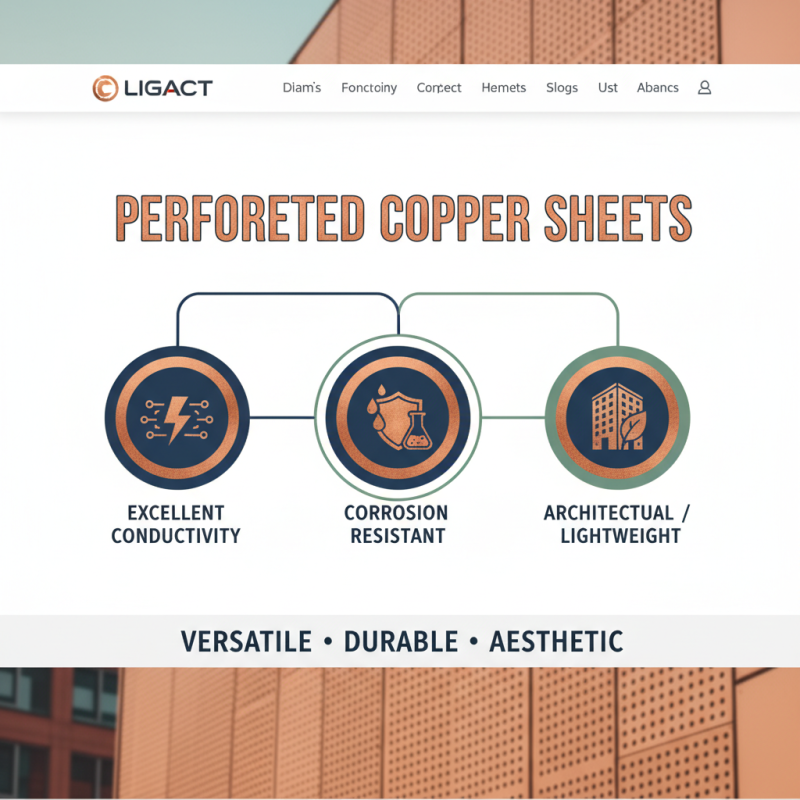

Perforated copper sheets are a versatile material widely utilized in various applications, thanks to their distinct features and inherent benefits. One of the primary attributes of perforated copper sheets is their excellent conductivity, making them ideal for electrical projects. Additionally, their ability to resist corrosion and oxidation enhances their durability, ensuring longevity in both indoor and outdoor environments. The holes in the sheets not only reduce weight and material costs but also provide aesthetic appeal, making them a fashionable choice for architectural designs.

When selecting the right perforated copper sheet for your project, consider the size and pattern of the perforations. Larger holes can facilitate airflow and drainage, which is beneficial for applications requiring ventilation. Conversely, smaller holes can enhance structural integrity and filtration. It's essential to match the perforation pattern to the specific needs of your project to maximize efficiency and effectiveness.

**Tips:** Always assess the thickness of the copper sheet in relation to your intended use. Thicker sheets are generally more robust and better suited for load-bearing applications, while thinner sheets can offer greater flexibility for intricate designs. Additionally, when selecting a finish, take into consideration how the sheet will be exposed to the elements or used in a finished product to ensure it meets your project's requirements.

When choosing a perforated copper sheet for your project, identifying your specific requirements is crucial. Start by determining the size of the sheet you need. Consider the dimensions of your project area and any design constraints you may have. Depending on the application, you might require larger sheets for extensive coverage or smaller pieces for detailed work. Measuring accurately ensures that the sheet will fit perfectly within your project's framework, avoiding unnecessary waste or additional modifications later on.

Next, the thickness of the copper sheet plays a significant role in functionality and performance. Thicker sheets provide greater strength and durability, making them suitable for structural applications or environments that experience heavy use. Conversely, thinner sheets are more lightweight and flexible, which can be advantageous for decorative purposes or projects that require intricate shaping. Additionally, the thickness can affect the hole patterns you'll be able to achieve, so it's essential to align your choice with both the practical uses and aesthetic goals of your project.

Lastly, consider the hole patterns available in the perforated copper sheets. The pattern can significantly influence both the aesthetic and functional performance of the material. Different configurations, such as round, square, or custom shapes, can affect light filtration, airflow, and even sound absorption depending on the intended use. By assessing your requirements for size, thickness, and hole patterns, you can make an informed decision that aligns perfectly with your project's objectives.

When selecting the right perforated copper sheet for your project, understanding the various grades and alloys of copper is crucial. Copper is known for its excellent electrical conductivity, corrosion resistance, and thermal conductivity, making it essential in diverse applications. According to the Copper Development Association, C11000 is one of the most widely used grades because it contains 99.9% copper, offering superior ductility and electrical performance, which is especially valuable in electrical and electronic applications.

For architectural and decorative projects, C26000 brass offers a blend of strength and aesthetic appeal. This alloy not only provides good corrosion resistance but also enhances machinability and workability traits, making it suitable for various designs and perforation patterns. Data from the International Copper Study Group indicates that approximately 25% of copper usage is in construction, highlighting the importance of selecting the right alloy for the longevity and visual quality of architectural installations.

Moreover, when opting for perforated sheets, considering the thickness and hole patterns in relation to the chosen alloy is essential. A study published in the Journal of Materials Science has shown that thinner sheets may be more vulnerable to deformation under stress if not paired with a robust alloy. Understanding these nuances ensures that the material you choose will meet the specific demands of your project, whether it’s for functional use or aesthetic enhancement.

| Copper Grade | Alloy Composition | Best Applications | Thickness Range (mm) | Perforation Type |

|---|---|---|---|---|

| C11000 | 99.9% Copper | Electrical applications, HVAC systems | 0.3 - 3.0 | Round holes, Square holes |

| C26000 | 70% Copper, 30% Zinc | Architectural features, Marine hardware | 0.5 - 4.0 | Slot holes, Custom shapes |

| C44000 | 90% Copper, 10% Nickel | Corrosion resistance applications | 0.2 - 3.5 | Round holes, Perforated sheets |

| C15200 | Copper with >99.99% purity | High conductivity applications, Electronics | 0.4 - 5.0 | Diamond holes, Decorative |

When searching for the right perforated copper sheet for your project, one crucial aspect to consider is the evaluation of suppliers, particularly regarding quality assurance and certification standards. Ensuring that a supplier adheres to recognized quality standards is imperative, as it directly impacts the performance and durability of the materials. Look for certifications such as ISO 9001, which indicates that the supplier has met international standards for quality management. This not only reflects their commitment to delivering high-quality products but also assures that they maintain consistent production processes.

Furthermore, it is essential to assess the supplier's quality assurance processes. Inquire about their testing methods and quality control measures throughout the production cycle. Reliable suppliers will provide detailed information about their inspection processes, including how they handle raw materials and their protocols for addressing defects. Engaging with suppliers who invest in rigorous quality assurance can save you time and resources in the long run, as it minimizes the risks of receiving subpar products that may hinder the success of your project. Opt for suppliers who are transparent about their quality measures and committed to continuous improvement, ensuring you receive a product that meets your project's specific requirements.

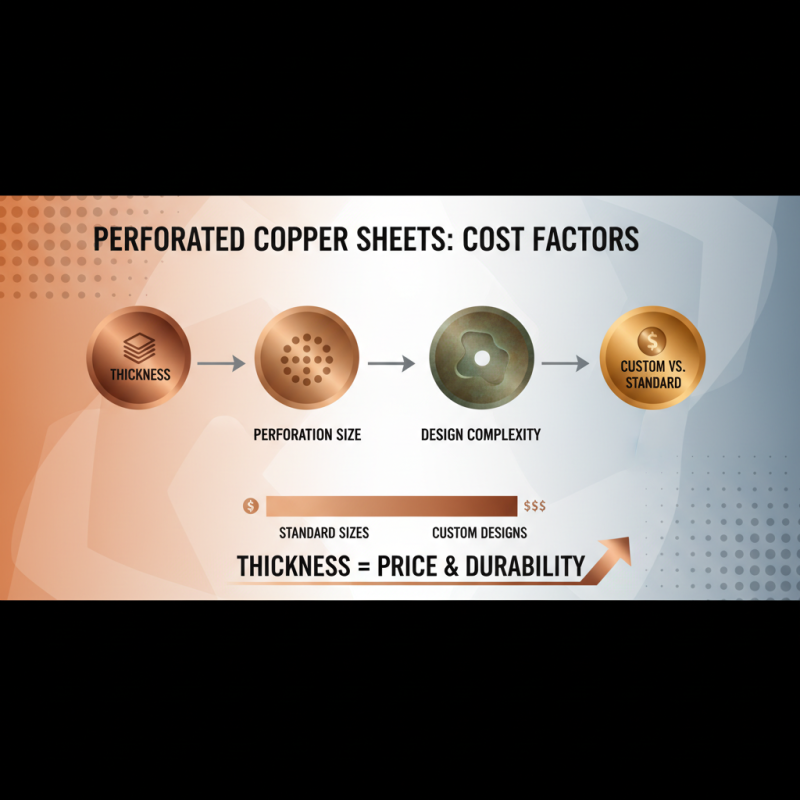

When budgeting for perforated copper sheets, it's essential to consider various cost factors that can impact your project. The price of perforated copper sheets can vary significantly based on factors such as sheet thickness, perforation size, and the complexity of the design. Standard sizes are usually more affordable, while custom designs may incur additional costs. Additionally, the thickness of the copper can influence not just the price, but also the durability and appearance of the finished product.

**Tips**: Always request quotes from multiple suppliers to compare prices. This can help you leverage competitive offers and gain insight into market rates. Don’t forget to factor in shipping costs, as these can add a significant amount to your overall budget, especially for large orders.

Another crucial aspect to consider is the quantity needed for your project. Often, purchasing in bulk can result in considerable savings per unit, so assess your project's requirements thoroughly. Considering future projects that may also utilize perforated copper sheets can streamline costs and reduce waste in the long run.

**Tips**: Look into wholesale options or suppliers that offer discounts for larger quantities. Planning ahead can lead to better financial choices and more efficient use of materials.